Dyeing and finishing process of rayon fabric

A fabric dyeing and finishing technology, applied in the field of dyeing and finishing technology, can solve the problems of poor wearing performance and easy wrinkling of fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] The dyeing and finishing process of a kind of rayon fabric disclosed by the invention specifically comprises the following process steps:

[0064] S1: Singeing, specifically singeing the fabric with a singeing machine to obtain a singeed gray cloth.

[0065] S2: Pretreatment, that is, descouring, bleaching, mercerizing, and presetting are performed on the burnt gray cloth obtained in step S1, so as to obtain a pretreated gray cloth.

[0066] S3: non-ironing finishing, specifically taking the pre-treated gray cloth obtained in step S2, putting it into the non-ironing modified solution for padding, the specific process of padding is as follows, the excess rate of padding is 85%, and the padding is completed The final gray cloth is dried at 80°C for 3 minutes, and then the preliminarily dried gray cloth is baked at 160°C for 3 minutes. After the baking is completed, the gray cloth is stacked for 24 hours to obtain a non-ironing gray cloth.

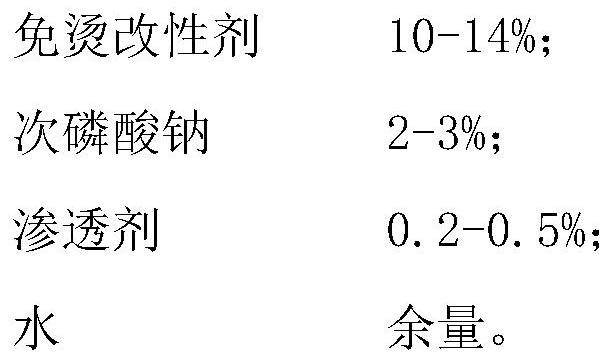

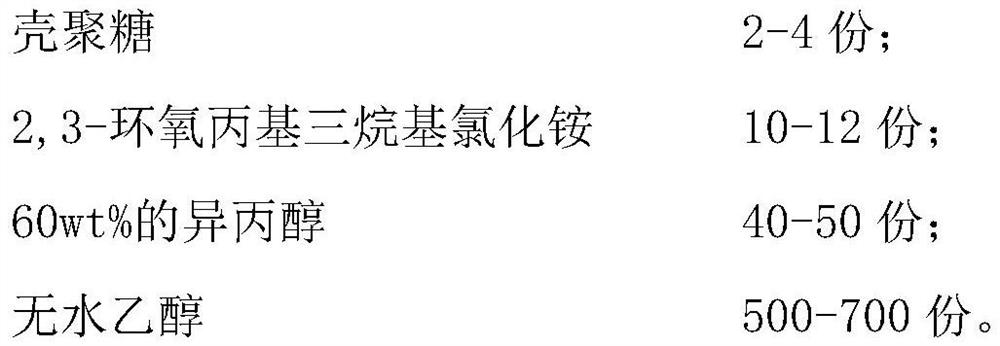

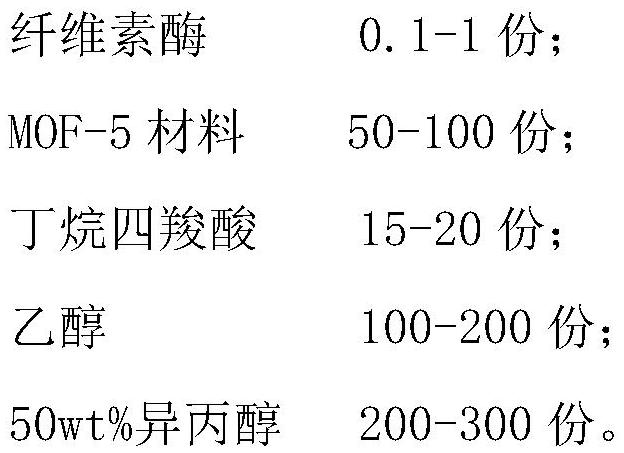

[0067] Wherein, the non-iron m...

Embodiment 43

[0114] The difference between Example 43 and Example 1 is that no hydrophobic treatment is performed between Step S4 and Step S5, that is, the post-treatment of Step S5 is directly performed on the pad-dyed gray fabric obtained in Step S4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com