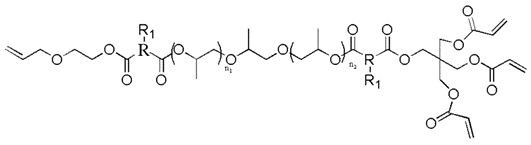

Free radical-cationic water-based hybrid light-cured resin and synthesis method thereof

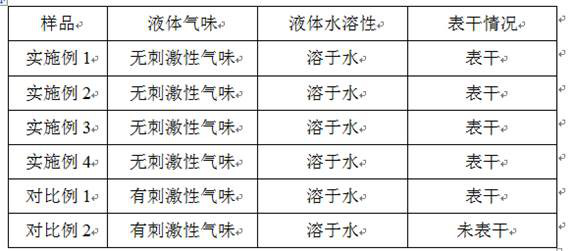

A hybrid light-curing, cationic technology, used in additive processing and other directions, can solve problems such as affecting the surface quality of printed products, sticky surface of printed products, and warping and deformation of printed products, so as to reduce production operation risks and reduce volume shrinkage. , to promote the effect of dry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

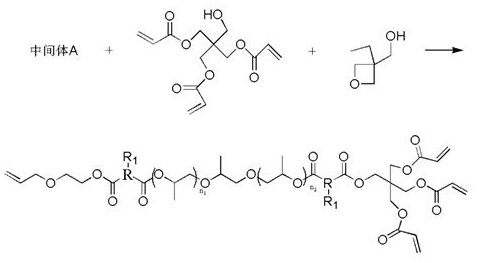

Method used

Image

Examples

Embodiment 1

[0031] After the reactor is preheated to 55°C, put 60g of toluene diisocyanate-trimethylolpropane adduct into the reactor, then dropwise add 18g of sodium hydroxysulfonate, 25g of reactive diluent morpholine acrylic acid, and the polymerization inhibitor p-hydroxybenzene Mixture of 0.05g of methyl ether and 0.01g of catalyst dibutyltin dilaurate, control the temperature at 55°C~60°C, keep warm for 1h~2h, add 120g of polyoxypropylene glycol, 3-ethyl -5g of 3-oxetanemethanol and 20g of pentaerythritol triacrylate, control the temperature at 70°C~75°C, keep warm for 2h~3h, test the isocyanate value, stop the reaction when the isocyanate value is zero, and obtain a hybrid light-curable water-based resin.

Embodiment 2

[0033] After the reaction kettle is preheated to 55°C, put 90g of isophorone diisocyanate trimer into the reaction kettle, then dropwise add 25g of sodium hydroxysulfonate, 58g of reactive diluent morpholine acrylic acid, and 0.05g of polymerization inhibitor p-hydroxyanisole g and the catalyst dibutyltin dilaurate 0.01g, control the temperature at 55°C~60°C, keep warm for 1h~2h, add 80g of polyoxypropylene glycol, 3-ethyl-3- 8g of oxetanemethanol and 14g of pentaerythritol triacrylate, control the temperature at 70°C~75°C, keep warm for 2h~3h, test the isocyanate value, stop the reaction when the isocyanate value is zero, and obtain a hybrid light-curable water-based resin.

Embodiment 3

[0035] After preheating the reaction kettle to 55°C, put 70g of hexamethylene diisocyanate trimer into the reaction kettle, then dropwise add 21g of sodium hydroxysulfonate, 45g of reactive diluent morpholine acrylic acid, and 0.05g of polymerization inhibitor p-hydroxyanisole g and the catalyst dibutyltin dilaurate 0.01g, control the temperature at 55°C~60°C, keep warm for 1h~2h, add 150g of polyoxypropylene glycol, 3-ethyl-3- Oxetane methanol 10g and pentaerythritol triacrylate 16g, control the temperature at 70°C~75°C, keep warm for 2h~3h, test the isocyanate value, stop the reaction when the isocyanate value is zero, and obtain a hybrid light-curable water-based resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com