Method for preparing thermally-driven purified water

A pure water, heat-driven technology, used in chemical instruments and methods, heating water/sewage treatment, water/sewage treatment, etc., can solve problems such as high pretreatment requirements, complex system design, and difficulty in direct use, reducing The effect of energy consumption, reducing energy consumption and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

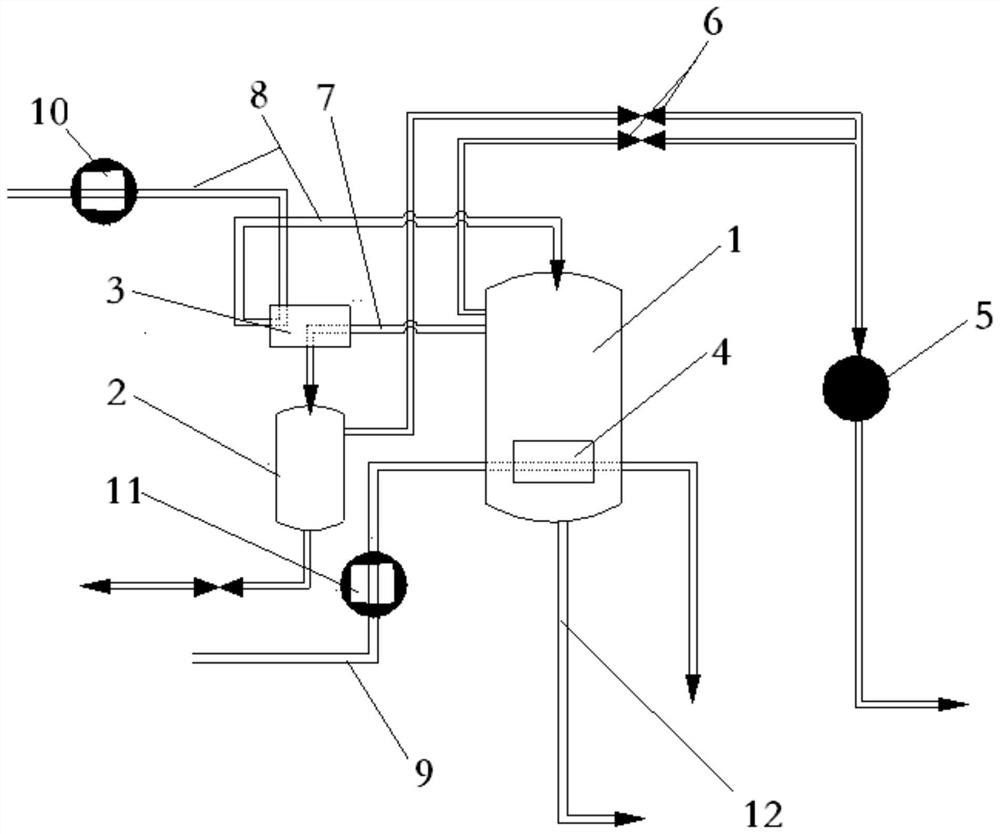

[0009] Referring to the accompanying drawings, the heat-driven pure water preparation method of the present application uses seawater as the water source for water production, and industrial wastewater with a temperature of about 30-50 degrees as the heat source for pure water production. The water production system of the present application contains Generating tank 1, water storage tank 2, condenser 3, evaporator 4, vacuum pump 5, valve 6, condensation pipeline 7, water source pipeline 8, heat source pipeline 9. The generator tank 1 and the vacuum pump 5 are connected with a pipeline, and a valve 6 is installed on the pipeline to prevent the gas from flowing back and keep the low-pressure environment in the generator tank 1 . The water storage tank 2 is connected with the vacuum pump 5 with a pipeline, and a valve 6 is installed on the pipeline to prevent the gas from flowing backward and keep the low-pressure environment in the water storage tank 2 . The condenser 3 connect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com