Water jet propulsion type underwater spherical heavy-load robot

A technology of water jet propulsion and robot, which is applied in the direction of propulsion engine, ship propulsion, propulsion components, etc. It can solve the problems of inability to realize heavy-duty operation, reduce concealment performance, and expose robots, so as to reduce the possibility and eliminate flow pulsation , Improve the effect of maneuverability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

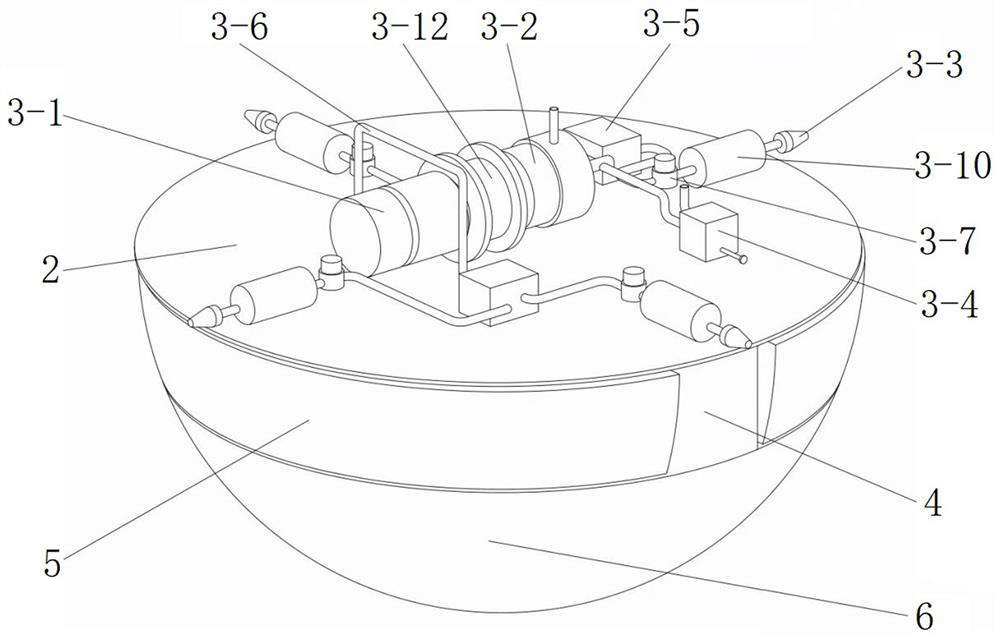

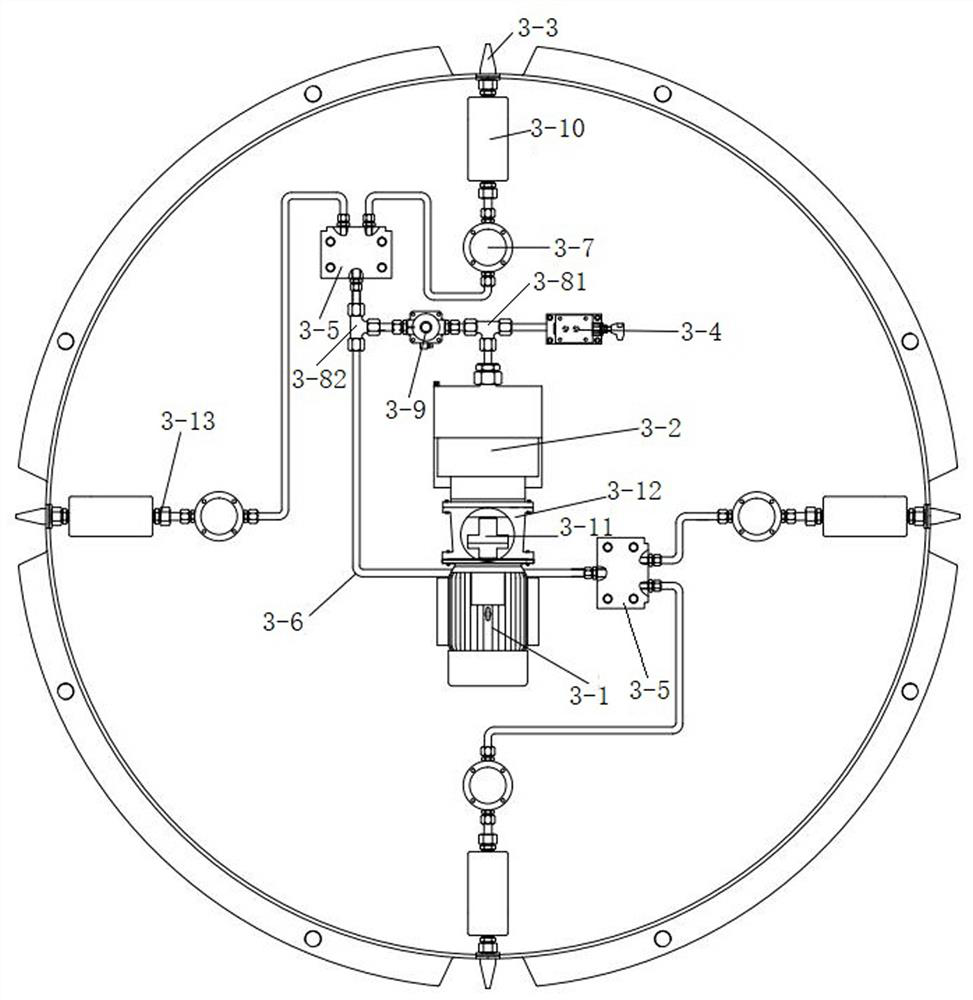

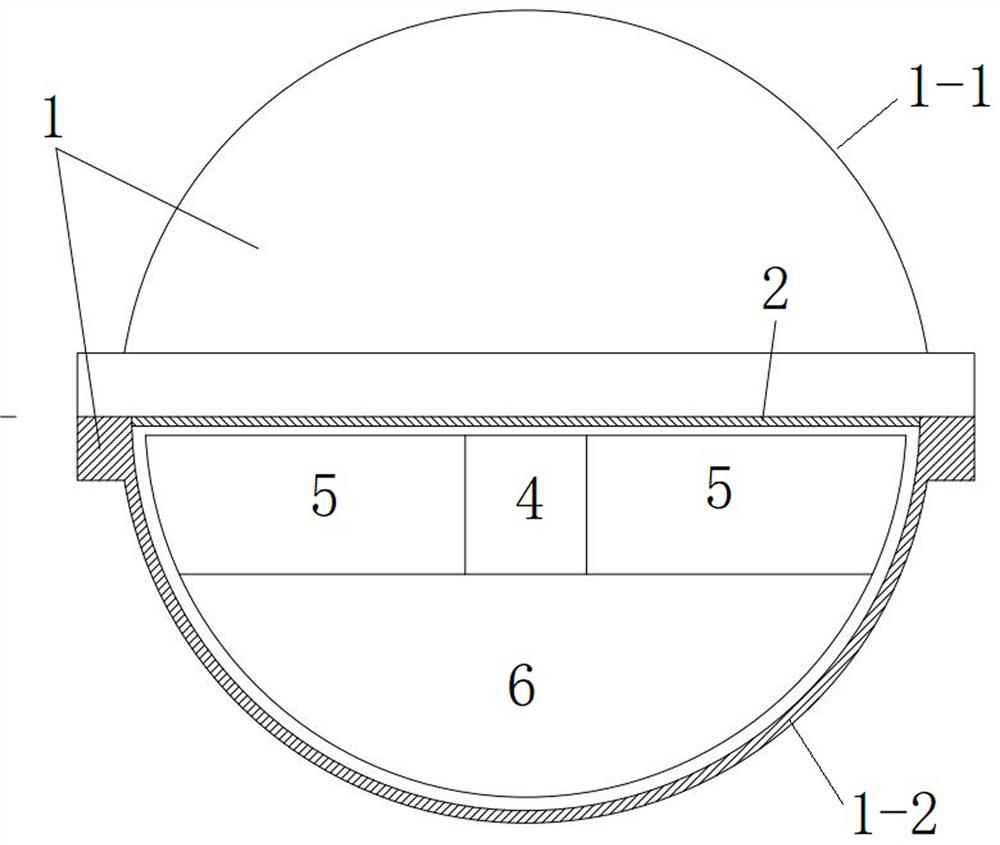

[0030] Such as Figure 1-5Shown, a kind of water-jet propulsion type underwater spherical heavy-duty robot comprises spherical shell 1, and spherical shell 1 comprises upper hemispherical shell 1-1 and lower hemispherical shell 1-2, and the lower periphery of upper hemispherical shell 1-1 An upper boss is provided, and a lower boss is arranged on the upper periphery of the lower hemispherical shell 1-2. The upper boss and the lower boss are correspondingly evenly distributed with longitudinal bolt holes, and a circle of diameters of 7 to 9 mm is provided on the inner side of the upper boss. The upper sealing groove and the inner side of the lower boss have a lower sealing groove with a diameter of 7-9mm. The upper hemispherical shell 1-1 and the lower hemispherical shell 1-2 are locked and fixed by eight bolts matching the corresponding number of longitudinal bolt holes, and through Sealing rings are installed in the upper and lower sealing grooves to seal the connection to pr...

Embodiment 2

[0035] The difference between this embodiment and Embodiment 1 is that the underwater spherical heavy-duty robot is also equipped with an intelligent control manipulator. Extend the grabbing cabin through the intelligent opening and closing window for deep-sea grabbing operations, and set up a storage bin in the grabbing cabin, and the submarine target objects grabbed by the intelligent control manipulator can be stored in the storage bin for later scientific research Wait.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com