Composite manufacturing method of corrosion-resistant impeller of sea water pump

A manufacturing method and sea water pump technology, which are applied to components, pumps, and pump components of a pumping device for elastic fluid, can solve the problems of large dilution rate of surfacing layer alloy, low degree of automation, limited process parameters, etc. To achieve the effect of improving the shape accuracy of the finished product, strong scalability, and ensuring corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

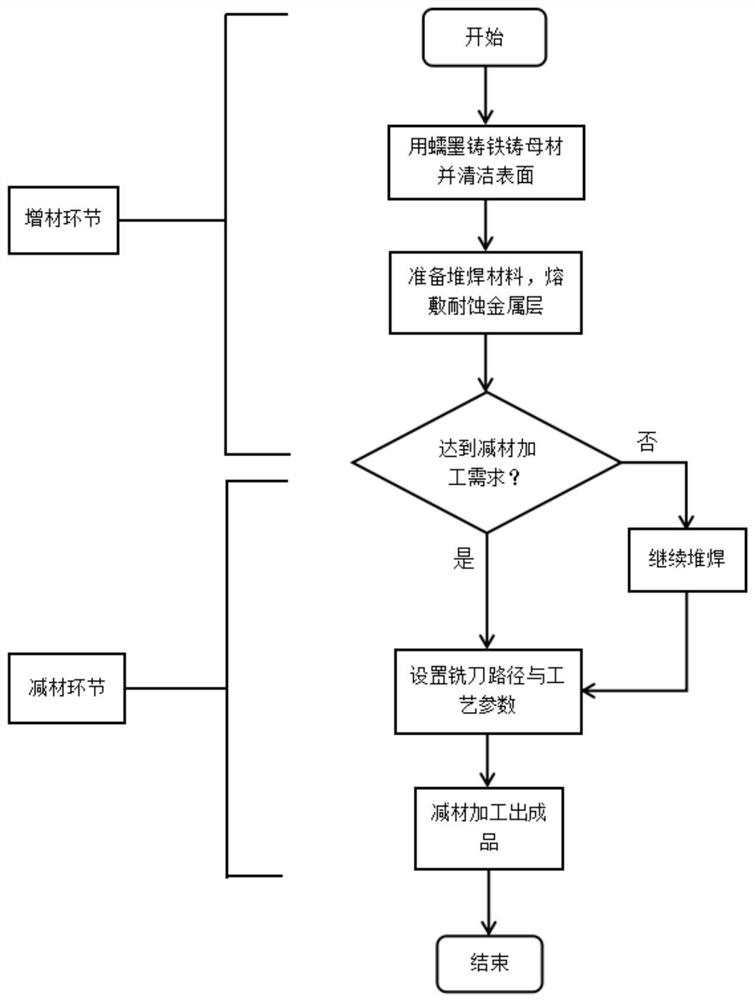

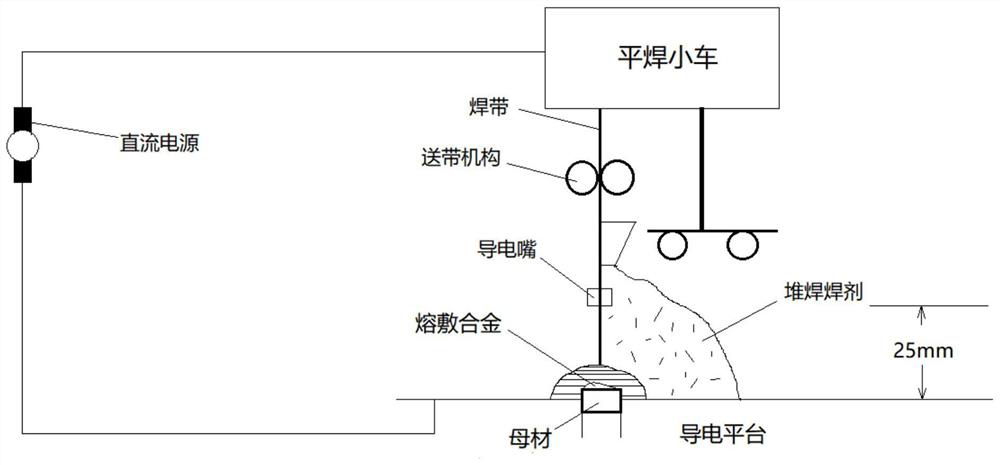

[0038] refer to Figure 1 to Figure 4 The embodiment of the composite manufacturing method of a seawater pump corrosion-resistant impeller of the present invention will be further described

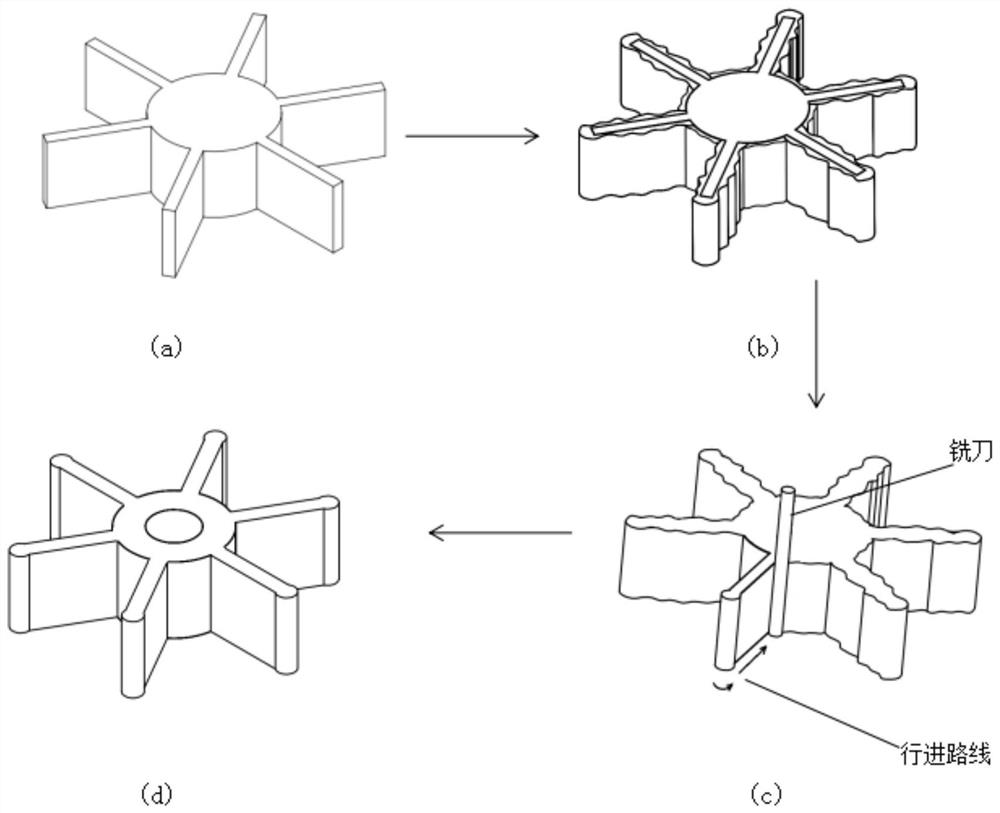

[0039] In order to get as image 3 -The six-leaf open impeller shown in (d) is now compositely manufactured by a composite manufacturing method of a seawater pump corrosion-resistant impeller provided by the present invention, and the steps are as follows:

[0040] The first is the additive link:

[0041] Use cast steel to cast the base metal to be surfacing. In this example, ZG200-400 is used as an example to cast, and the blank is obtained as image 3 -As shown in (a), note that its geometric size should be "indented" by at least 3mm compared to the target product, to reserve space for the corrosion-resistant alloy layer. The base material needs to be pretreated before use, and the runners and burrs should be repaired, and then polished with sandpaper The scale and sand inclusions ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com