Rotary machine fault intelligent diagnosis method based on fuzzy soft morphology graph recognition

A rotating machinery and graphic recognition technology, applied in the field of high-speed rotating machinery fault diagnosis and signal processing, can solve problems such as difficult knowledge rules, difficult automatic extraction of information, and insufficient use of information, so as to improve accuracy, improve diagnosis speed and Accuracy, the effect of improving the level of automatic diagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

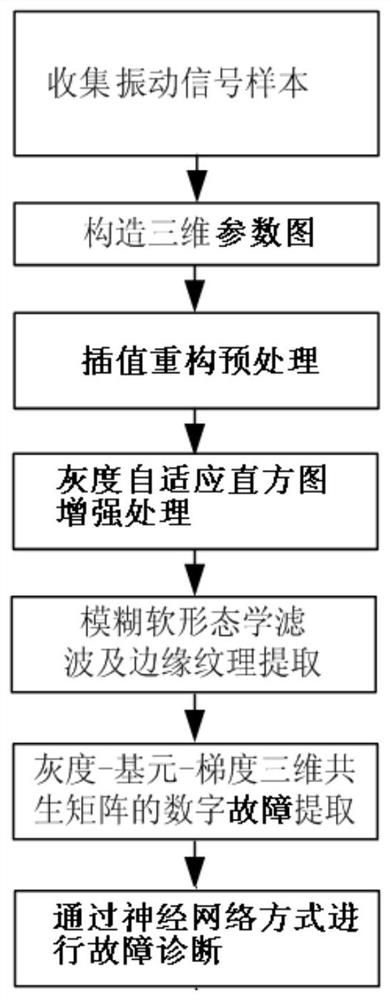

[0063] Diagnosis graphic information has been effectively used. In the past fault diagnosis, due to the difficulty of graphic feature extraction, it is difficult to be directly used in the fault diagnosis of rotating machinery, so the diagnostic accuracy is low. The invention constructs fuzzy soft morphological parameter graphic feature extraction and preprocessing methods, which can effectively obtain vibration information and improve the accuracy of fault diagnosis.

[0064] The invention relates to the field of high-speed rotating machinery fault diagnosis technology and signal processing technology. It is the first domestic rotating machinery fault diagnosis method based on fuzzy soft morphology graphic recognition technology, and can be applied to petrochemical, metallurgy, electric power, aviation and aerospace industries. Some large rotating machinery as the main production tools such as aero-engines, gas turbines, fans, steam turbines, compressors and generators.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com