Test method and test system for mechanical properties of material

A technology of mechanical properties and test methods, applied in the direction of analyzing materials, using stable bending force to test material strength, and using stable tension/pressure to test material strength, etc., can solve problems such as low work efficiency and improve accuracy. Effect

Pending Publication Date: 2020-11-17

NAT POLYMER MATERIALS IND INNOVATION CENT CO LTD

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] In order to solve the problem of low work efficiency caused by relying too much on manual feeding in the prior art, the present invention provides a test method and test system for the mechanical properties of materials, which can effectively solve the above problems

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment I

[0088] Specific embodiment 1: as Figure 5 , in order to improve work efficiency, a control cabinet 1, 2 tensile test assemblies 2, 3 bending test assemblies 5, and a feed bin 7 are arranged on the base plate 9; the tensile test assembly 2, bending test assembly 5 1. The feed bin 7 takes the conveying device 4 as the center of circle and surrounds the outside of the conveying device 4, which facilitates the work of the conveying device 4.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

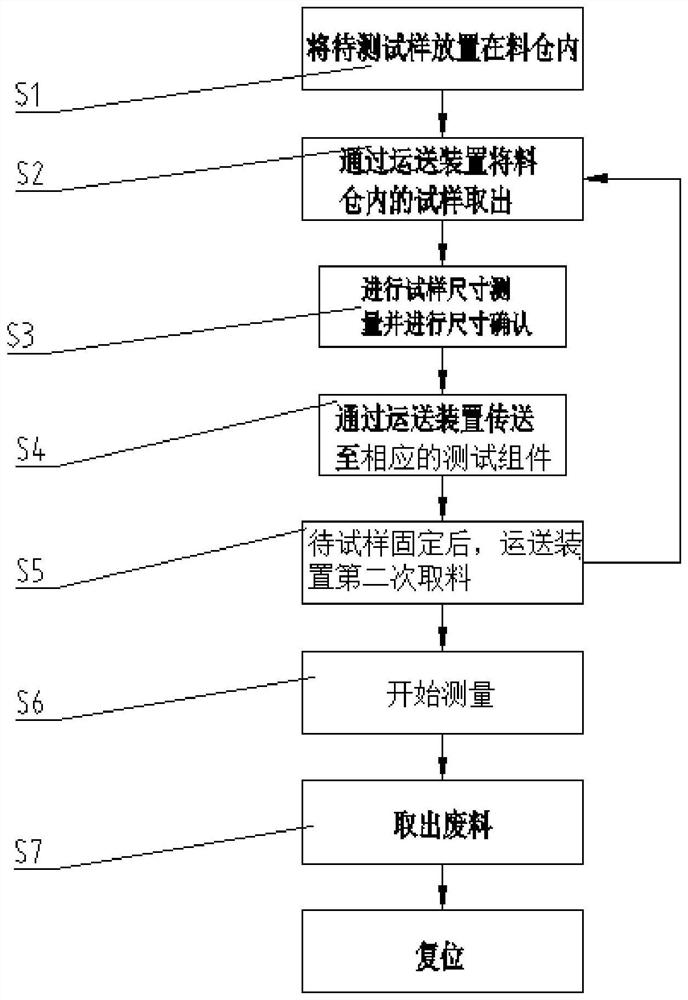

In order to solve the problem of low working efficiency caused by excessively depending on manual feeding in the prior art, the invention provides the testing method and the testing system for the mechanical properties of the material, a conveying device is controlled by a control center to convey a to-be-tested sample to a testing station, and a tensile test or a bending test is carried out; after the work is completed, the waste is taken out through the waste taking-out device; in addition, when a tensile test or a bending test is carried out, scheduling optimization is carried out on the conveying device by adopting a chicken swarm algorithm and a genetic second-generation hybrid algorithm, so that the productivity in unit time is improved. According to the method, a conveying device iscontrolled by a control center to convey a to-be-tested sample to a test station, a tensile test or a bending test is carried out, and after the above work is completed, waste is taken out through awaste taking-out device; and when a tensile test or a bending test is carried out, scheduling optimization is carried out on the conveying device, so that the productivity in unit time is improved, and the test efficiency is improved.

Description

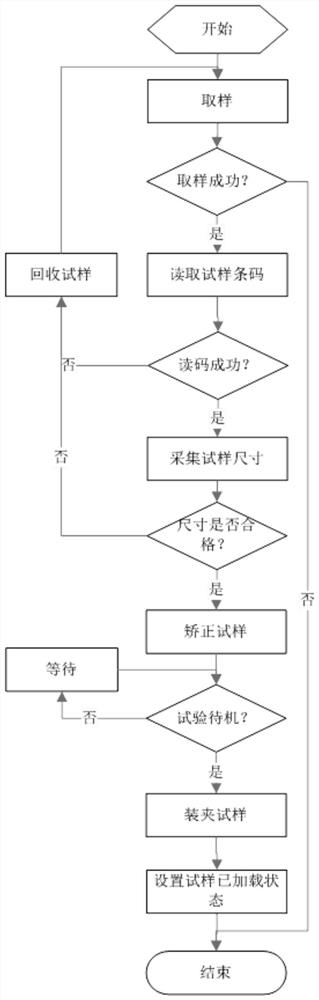

technical field [0001] The invention relates to the field of material performance testing, in particular to a testing method and testing system for the mechanical properties of materials. Background technique [0002] A standard sample is actually a "reference value" that provides one or more quantities of a substance as a "reference value" for the accuracy of other measurements. Therefore, the measurement requirements for the sample are relatively high. [0003] Existing methods for sample measurement usually use manual loading, tensile testing and bending testing are performed through a tensile machine, and then the data is recorded, and the waste is manually removed, and then the measurement of the next sample is carried out. The detection process mostly relies on manual labor, and the work efficiency is low. Contents of the invention [0004] In order to solve the problem of low work efficiency caused by relying too much on manual feeding in the prior art, the presen...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N35/00G01N35/10G01N3/08G01N3/20

CPCG01N3/08G01N3/20G01N35/00584G01N35/0092G01N35/0099G01N35/1081G01N2035/0094G01N2203/0017G01N2203/0023

Inventor 吴博庞承焕程春锋李卫领肖星

Owner NAT POLYMER MATERIALS IND INNOVATION CENT CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com