Method for testing sealing performance of crimping terminal assembly of crimping electric connector for cable network

A technology of crimping terminals and a testing method, which is applied in the field of tightness testing of crimping terminal components of crimping electrical connectors for cable nets, and achieves the effects of improving efficiency, increasing the number of simultaneous detections, and quickly detecting leaks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

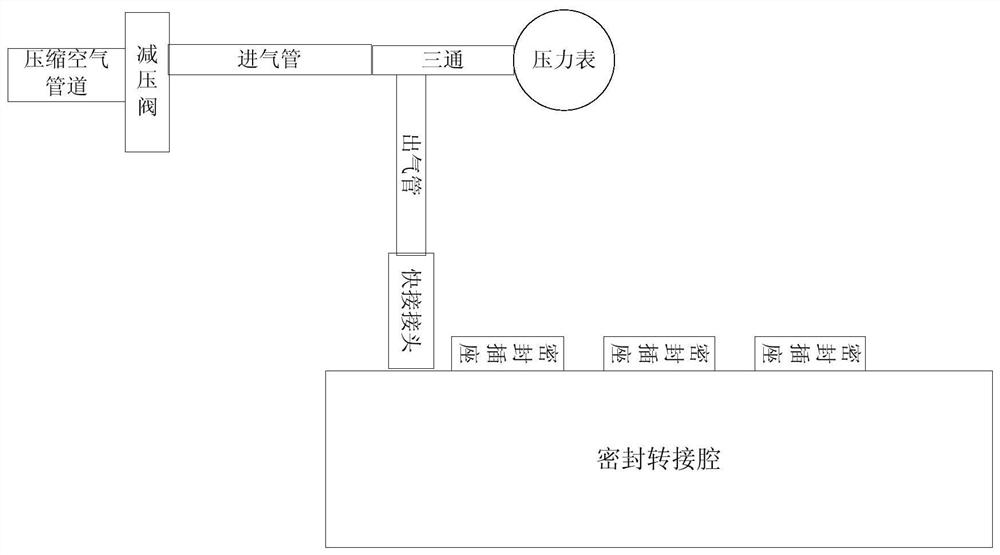

[0030] (1) Design a set of sealing test device for crimp terminal assembly

[0031] Including transparent water storage, pressure reducing valve, pressure gauge, compressed air supply pipe, tee, sealed adapter chamber, test tube fixing tool, test tube, L-shaped bracket, quick connector, sealed socket. And fix the pressure reducing valve, tee and pressure gauge on the L-shaped bracket. Connect the tightness test device to the compressed air supply pipe, and the pressure of the compressed air should not be less than 0.2MPa. Fill the water reservoir with water, the depth of water should be able to submerge the vertically placed 15ml, Φ16mm test tube and the sealed adapter chamber with a height of 80mm. It is required that the sealed transfer cavity is placed in the water storage under 0.2MPa, and there is no obvious air bubble leakage from the sealed transfer cavity. Close the compressed air valve.

[0032] Including 1 transparent water reservoir, 1 pressure reducing valve, 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com