Sliding directional intelligent control method based on GRU

An intelligent control and sliding drilling technology, which is applied to the automatic control system of drilling, directional drilling, adaptive control, etc., can solve the problems of gradient disappearance, poor model accuracy and pan-China performance, and low efficiency, so as to solve the problem of gradient disappearance, The effect of solving gradient explosion and improving training efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

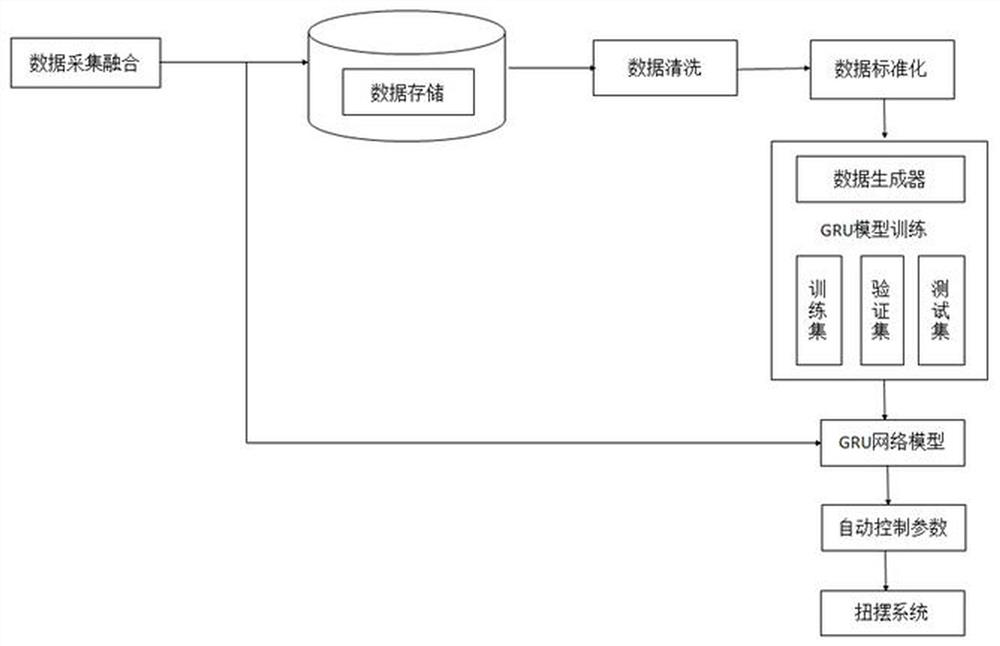

[0032] The invention discloses a GRU-based sliding orientation intelligent control method, such as figure 1 As shown, it includes the following steps:

[0033] Step 1: Data acquisition fusion and storage

[0034] Obtain the on-site initial sample data of the torsion pendulum system, MWD system and integrated mud logging system in sliding drilling, classify and integrate the obtained initial sample data, and store the integrated initial sample data in the database.

[0035] In this step, the initial sample data comes from the three systems of torsion, MWD, and comprehensive mud logging. The data can be the current real-time collected data or the previous collected data to provide real field data for model training.

[0036] Step 2: Data cleaning and standardization

[0037] Due to the large amount of data collected on site and many types, some data have no practical guiding significance for sliding orientation operations. Therefore, data cleaning should be performed on the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com