Ingot casting furnace with tail gas treatment function

A technology for exhaust gas treatment and ingot casting furnace, which is applied in the growth of polycrystalline materials, crystal growth, single crystal growth, etc., can solve the problems of affecting the application effect of polycrystalline silicon solar panels, high content of carbon and oxygen elements, and deterioration of the quality of polycrystalline silicon ingots. , to achieve the effect of preventing life safety, improving utilization, and using safe and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

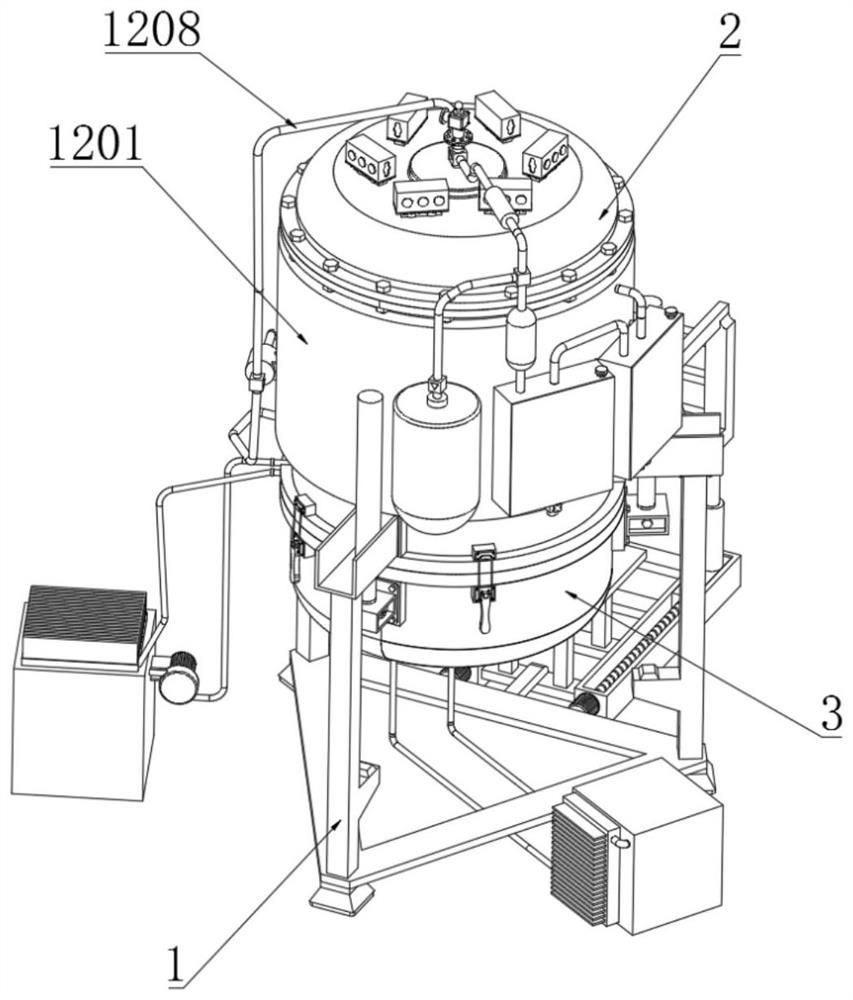

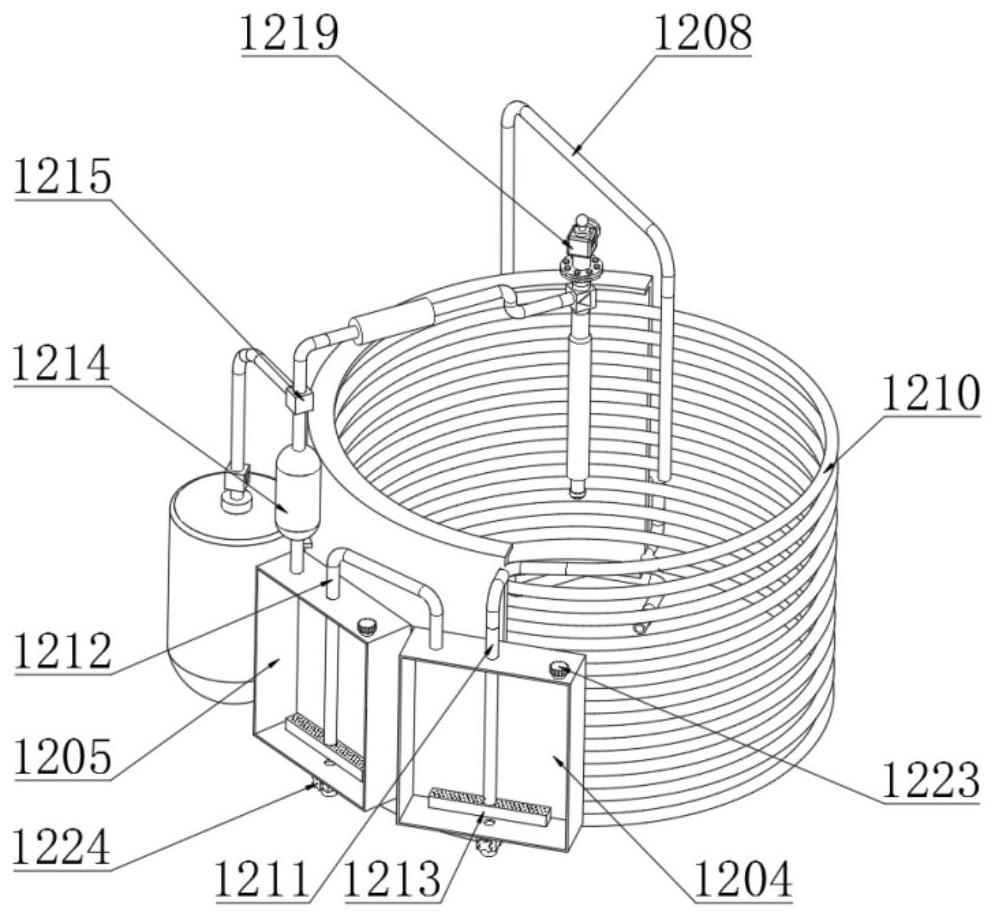

[0042] Such as Figure 1-16 As shown, the outer side of the upper furnace body 2 is provided with an exhaust gas treatment mechanism 12;

[0043] Exhaust gas treatment mechanism 12 includes insulation cover 1201, intake vertical pipe 1202, circulating air pump 1203, front scrubber box 1204, rear scrubber box 1205, front three-way valve 1206, lower exhaust pipe 1207, upper exhaust pipe 1208, lower guide Air pipe 1209, spiral circulation pipe 1210, upper exhaust pipe 1211, middle air pipe 1212, distribution square pipe 1213, drying barrel 1214, middle three-way valve 1215, upper air pipe 1216, heating jacket 1217, rear three-way valve 1218, control Valve 1219, side air guide pipe 1220, sealing valve 1221, gas tank 1222, liquid filling port 1223 and liquid discharge valve 1224;

[0044] The outer side of the upper furnace body 2 is fixedly equipped with a thermal insulation cover 1201, and the top of the upper furnace body 2 is connected with an inlet vertical pipe 1202 whose in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com