Prolinol rapid desulfurizer and preparation method thereof

A technology of desulfurization agent and prolinol, which is applied in the field of prolinol fast desulfurization agent and its preparation, can solve the problem that it is difficult to meet the needs of various catalytic reaction sites at the same time, the easy recombination of photogenerated electrons and holes, and the utilization rate of visible light Low-level problems, to achieve the effect of easy operation, easy access to raw materials, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

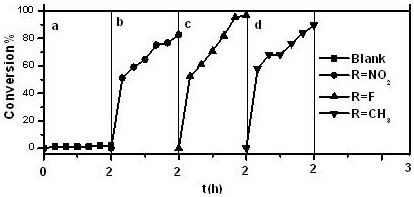

Embodiment 1

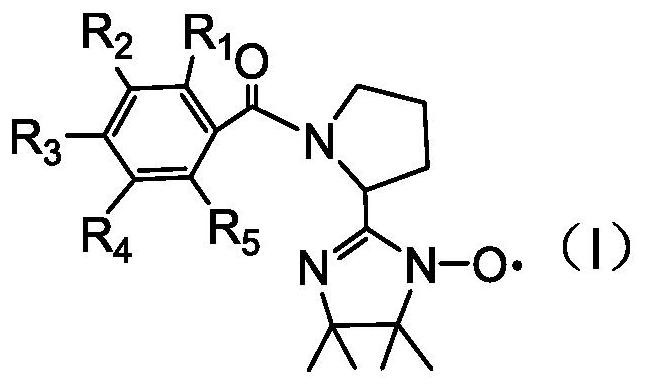

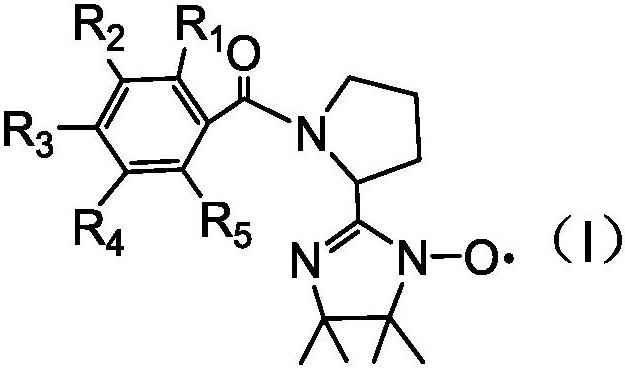

[0025] Embodiment 1: a kind of prolinol fast desulfurizer, prepared by the following steps:

[0026] Weigh 0.54g of 1-(4-methylphenyl)pyrrole-2-carbaldehyde (2.5mmol), and weigh (2.5mmol) 0.37g of 2-3-dihydroxyamine-2-3-dimethyl with the same molar ratio Butane and 20ml chromatographic methanol were put into a one-necked flask and heated to reflux for 24 hours. The methanol solvent was removed by rotary evaporation, and the remaining substance was dissolved in 20 ml of dichloromethane, placed in an ice-water bath, and stirred. Add sodium nitrite (103 mg, 1.5 mmol) and stir at reflux for 1 h. The dichloromethane was removed under reduced pressure to obtain a deep red solution, which was dried under reduced pressure. The crude product was analyzed and purified by gradient elution column chromatography on a silica gel column to obtain 0.56 g of a light yellow viscous product radical with a yield of 68%. R f =0.58(CH 2 Cl 2 / CH 3 OH,15:1).EI-MS(m / z)330.2181[M] + .IR(KBr)340...

Embodiment 2

[0027] Embodiment 2: a kind of prolinol fast desulfurizer, prepared by the following steps:

[0028] Weigh 0.62g of 1-(4-nitrophenyl)pyrrole-2-carbaldehyde (2.5mmol), and weigh (2.5mmol) 0.37g of 2-3-dihydroxyamine-2-3-dimethyl with the same molar ratio Butane and 20ml chromatographic methanol were put into a one-necked flask and heated to reflux for 24 hours. The methanol solvent was removed by rotary evaporation, and the remaining substance was dissolved in 20 ml of dichloromethane, placed in an ice-water bath, and stirred. Add sodium nitrite (103 mg, 1.5 mmol) and stir at reflux for 1 h. The dichloromethane was removed under reduced pressure to obtain a deep red solution, which was dried under reduced pressure. The crude product was analyzed and purified by gradient elution column chromatography on a silica gel column to obtain 0.54 g of a light yellow viscous product radical with a yield of 60%. R f =0.49(CH 2 Cl 2 / CH 3 OH,15:1).EI-MS(m / z)360.1562[M] + .IR(KBr)3359...

Embodiment 3

[0029] Embodiment 3: a kind of prolinol fast desulfurizer, prepared by the following steps:

[0030] Weigh 0.55g of 1-(3-fluorophenyl)pyrrole-2-carbaldehyde (2.5mmol), and weigh (2.5mmol) 0.37g of 2-3-dihydroxyamine-2-3-dimethyl with the same molar ratio Butane and 20ml chromatographic methanol were put into a one-necked flask and heated to reflux for 24 hours. The methanol solvent was removed by rotary evaporation, and the remaining substance was dissolved in 20 ml of dichloromethane, placed in an ice-water bath, and stirred. Add sodium nitrite (103 mg, 1.5 mmol) and stir under reflux for 1 h. The dichloromethane was removed under reduced pressure to obtain a dark red solution, which was dried under reduced pressure. The crude product was analyzed and purified by gradient elution column chromatography on a silica gel column to obtain 0.45 g of a light yellow viscous product free radical with a yield of 54%. R f =0.61 (CH 2 Cl 2 / CH 3 OH,15:1), EI-MS (m / z) 334.1924[M] +...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com