Magnesia sulfoaluminate cement composition as well as product and manufacturing method thereof

A technology of magnesia sulphoaluminate and cement composition, which is applied in the field of building materials, can solve problems such as strength attenuation, achieve long service life, improve impermeability, and improve the effect of sulfate erosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Making a non-combustible inorganic composite board

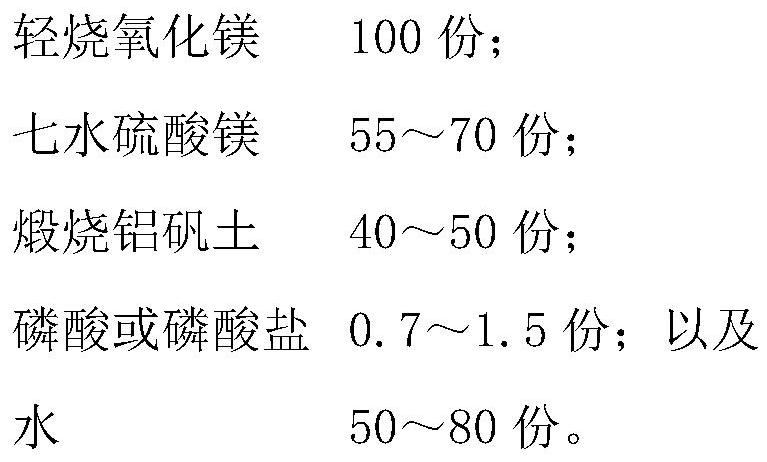

[0030] The raw materials used are light-burned magnesia and calcined bauxite. After testing, the light-burned magnesia contains 63% active MgO, and the calcined bauxite contains active Al. 2 o 3 65%, active SiO 2 15%. The proportion of magnesia sulfoaluminate cement screened in the test is as follows: 100 parts of light-burned magnesia, 45 parts of calcined bauxite, 69 parts of magnesium sulfate heptahydrate, 0.7 parts of phosphoric acid, and 76 parts of water. It is also necessary to select a matching glass fiber mesh cloth according to the thickness of the non-combustible inorganic composite board. Make a solution of magnesium sulfate heptahydrate, phosphoric acid and water, and stir it with calcined bauxite and light-burned magnesia to form a clean slurry. After the clean slurry is made, add 30 parts of sawdust and mix it into a slurry in a mill with loosening function, and roll it with the upper and...

Embodiment 2

[0031] Example 2: Making Glass Magnesium Air Duct Board

[0032] The raw materials used are light-burned magnesia and calcined bauxite. After testing, the light-burned magnesia contains 60% active MgO, and the calcined bauxite contains 56% active Al2O3 and 18% active SiO2. The ratio of the magnesia sulfoaluminate cement screened out in the test is as follows: 100 parts of light-burned magnesia, 47 parts of calcined bauxite, 63 parts of magnesium sulfate heptahydrate, 1.5 parts of sodium hexametaphosphate, 60 parts of water share. It is also necessary to use 90-110g glass fiber twisted mesh cloth per square meter and molded polystyrene foam plastic board for heat insulation with a thickness of 20mm. Make a solution of magnesium sulfate heptahydrate, sodium hexametaphosphate and water, and stir it with calcined bauxite to form a clean slurry. After the clean slurry is made, the upper and lower layers of glass fiber twisted mesh cloth are respectively passed through the clean s...

Embodiment 3

[0033] Example 3: Making straw-based panels

[0034]The raw materials used are light-burned magnesia and calcined bauxite. The light-burned magnesia contains 65% active MgO, the calcined bauxite contains 58% active Al2O3 and 16% active SiO2. The ratio of magnesia sulfoaluminate cement screened out in the test is as follows: 100 parts of light-burned magnesia, 50 parts of calcined bauxite, 69 parts of magnesium sulfate heptahydrate, 1.0 part of phosphoric acid, and 77 parts of water. The straw is selected from wheat straw, and the straw with hollow structure is cut open by cutting method and processed into long strips with a length of 20-25mm and a width of 0.8-1.8mm. Make a solution of magnesium sulfate heptahydrate, phosphoric acid and water, and stir it with calcined bauxite and light-burned magnesia to form a clean slurry. After the clean slurry is made, it is mixed with 110 parts of strip-shaped wheat straw in a roller mill with a loosening function to form a semi-dry slu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com