Device and method for filtering and removing organic pollutants in water by electro-catalytic ozone adsorption membrane

A technology of organic pollutants and electrocatalysis, which is applied in the field of water treatment, can solve the problems of low concentration and limited degradation rate, and achieve the effect of increasing removal rate, enhancing mass transfer, and promoting catalytic degradation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

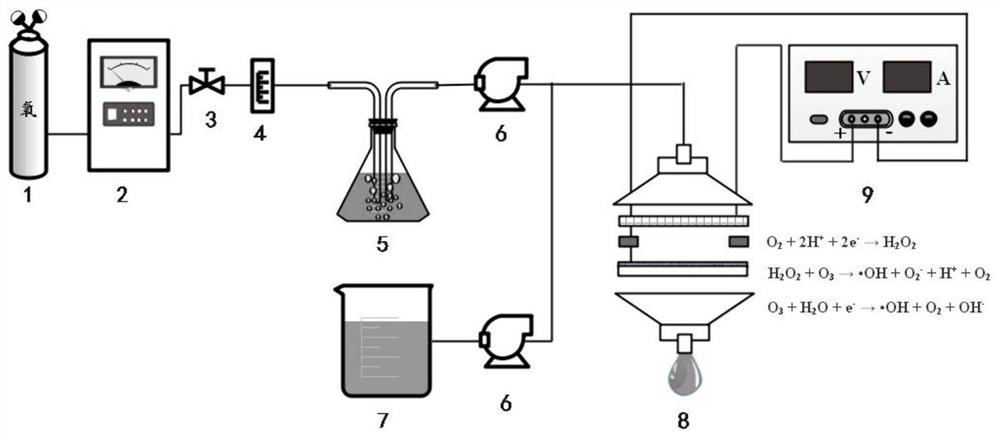

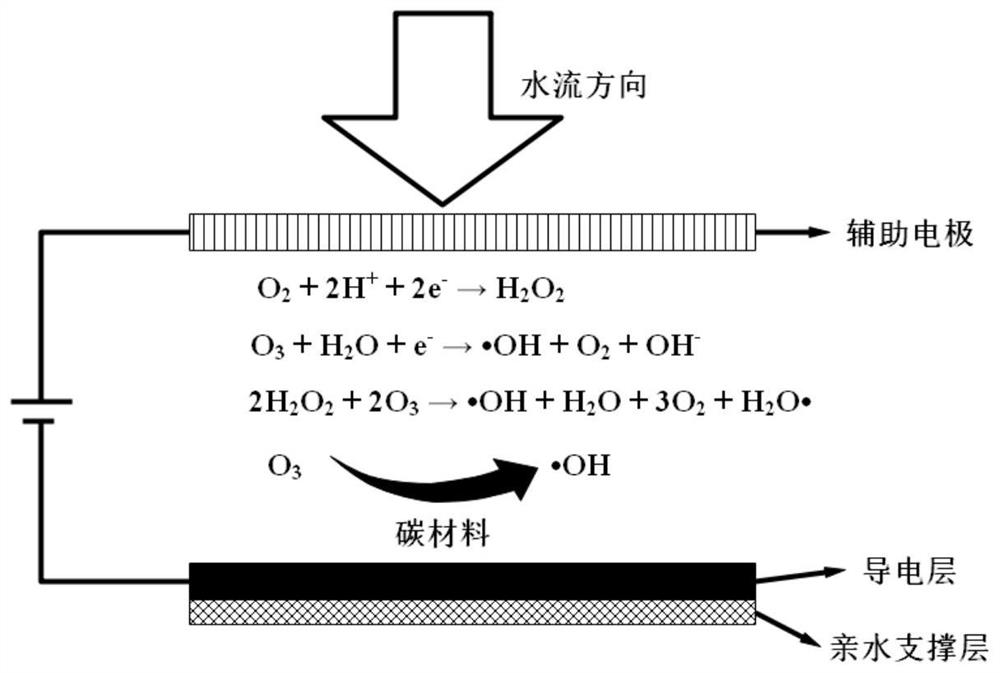

[0040] In this embodiment, the electrocatalytic ozone filter membrane electrode is pressed by commercial carbon cloth (conductive layer) and support layer (hydrophilic filter membrane), and is connected to an external power supply. The organic pollutants in the influent are first adsorbed on the carbon cloth layer, and at the same time, the filter membrane electrode electrocatalyzes the reduction of oxygen to generate H in situ 2 o 2 , react with ozone in the influent water to generate strong oxidizing free radicals, then oxidize the strong oxidizing free radicals generated by the reaction with ozone, and finally be degraded, and the above-mentioned continuous reaction of adsorption and degradation in the filtration process is carried out in a continuous cycle, so as to realize the organic pollutants in water Long-term continuous and efficient removal.

[0041] The electrocatalytic ozone membrane filtration reactor is characterized in that: the reactor feed water is continuou...

Embodiment 2

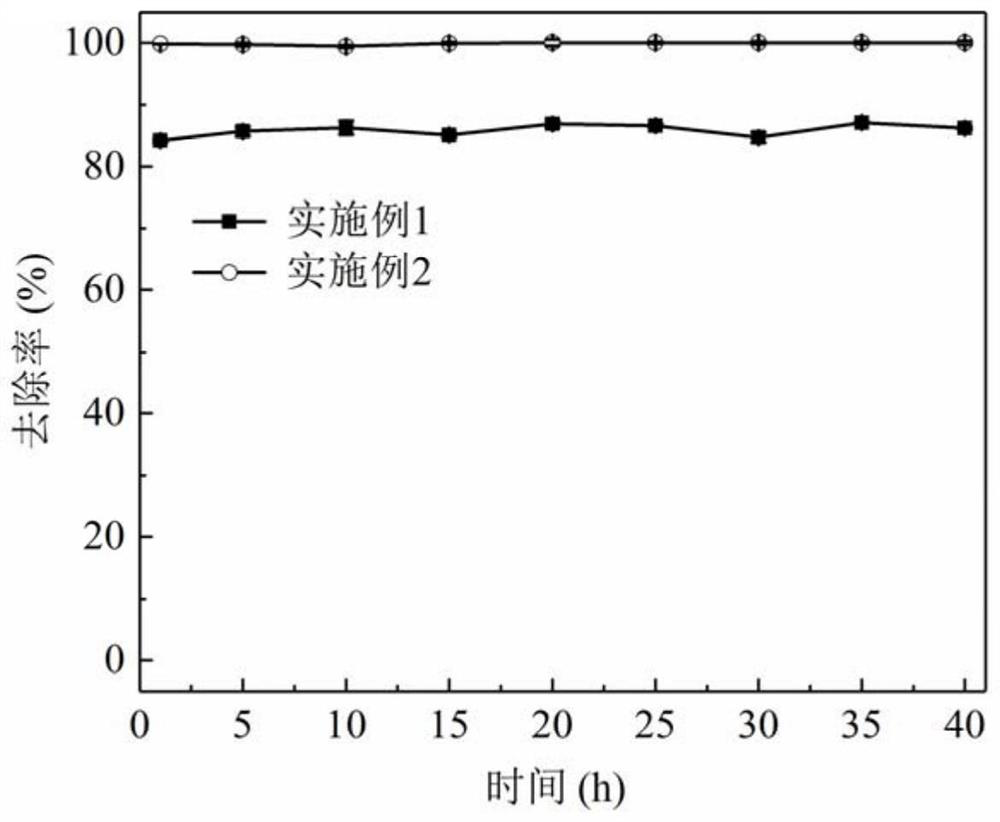

[0044] Except that the electrocatalytic ozone filter membrane electrodes are made of carbon nanotubes and hydrophilic membranes, the other device configurations are the same as in Example 1. The carbon nanotube electrocatalytic ozone filter membrane electrode is composed of a carbon nanotube material tube conductive layer and a base film. Its preparation method is to prepare a uniformly dispersed carbon nanotube dispersion solution first, and then vacuum filter or pressurize it. Loaded on the basement membrane surface. The loading capacity of conductive nanomaterials is 22g / m 2 , the thickness of the conductive layer is 85 μm, the experimental results can be found in image 3 and Table 1.

Embodiment 3

[0046] Except that rhodamine B (RhB) concentration is 10mg L in the raw water stock solution -1 , except that the filtration time was 120min, all the other devices and experimental parameters were the same as in Example 1. For experimental results, see Figure 4 and Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com