MVR evaporative crystallization equipment for high-salinity wastewater in pharmaceutical industry

A high-salt wastewater, evaporation and crystallization technology, applied in the direction of water pollutants, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of low crystal purity, complex structure, no energy saving, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

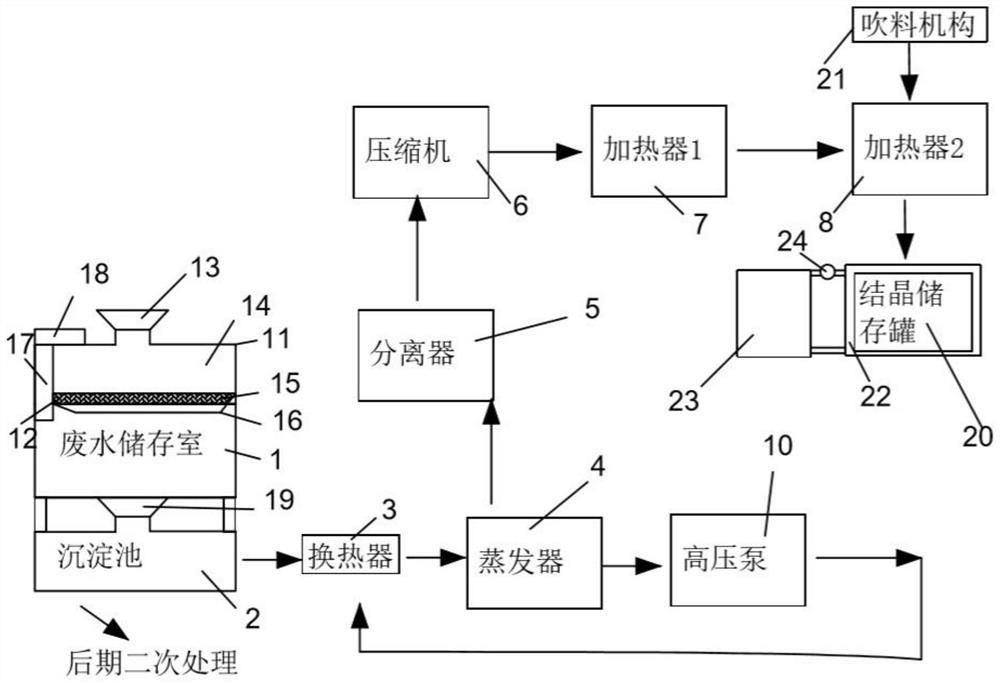

[0025] see figure 1 , this embodiment provides a high-salt wastewater MVR evaporation and crystallization equipment in the pharmaceutical industry, including a medical wastewater storage room 1, a chemical sedimentation tank 2 is provided below the medical wastewater storage room 1, and the top of the chemical sedimentation tank 2 is drained The outlet of the chemical precipitation tank 2 is connected to a heat exchanger 3, and the impurities discharged from the slag discharge port below the chemical precipitation tank 2 are subjected to secondary treatment. The output of the heat exchanger 3 is connected to an evaporator 4, and the steam outlet of the evaporator 4 A separator 5 is connected, and the secondary steam outlet of the separator 5 is connected with a compressor 6, and the output of the compressor 6 is connected with a first heater 7 and a second heater 8 in sequence, and the second heater The heating temperature of 8 is higher than the heating temperature of the fir...

Embodiment 2

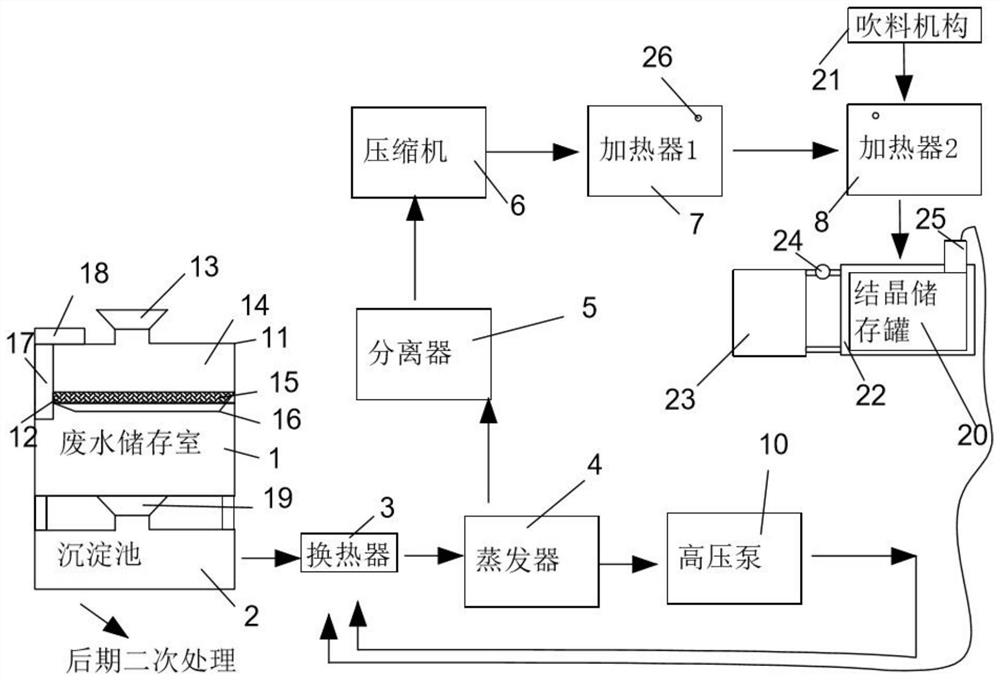

[0031] see figure 2 , this embodiment provides a high-salt wastewater MVR evaporation and crystallization equipment in the pharmaceutical industry. In order to further save energy, a hot gas outlet 25 is provided above the crystallization storage tank 20, and the hot gas outlet 25 is sent into the heat exchanger 3 through a pipeline. And it is connected with the output of the high-pressure pump 10, and the energy-saving effect is improved by sending the generated preheat back to the heat exchanger 3.

[0032] Further, in order to facilitate automatic temperature monitoring, a temperature detector 26 for detecting internal temperature is provided in the first heater 7 and the second heater 8, and the temperature is automatically detected by setting the temperature detector 26 .

Embodiment 3

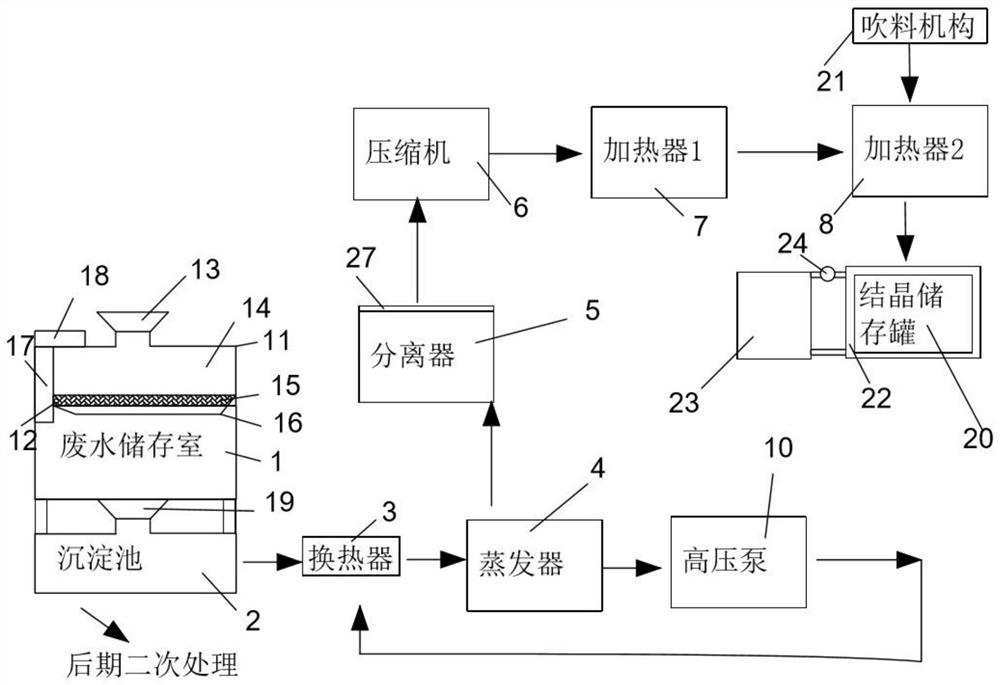

[0034] see image 3 , the present embodiment provides a high-salt wastewater MVR evaporation and crystallization equipment in the pharmaceutical industry. Further, to improve the filtering effect, a second filter screen 27 is connected to the secondary steam outlet of the separator 5. By setting the second filter screen 27 Improve the filtering effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com