Three-dimensional network graphene-based tensile strain sensor and its preparation method

A graphene-based, tensile strain technology, applied in graphene, chemical instruments and methods, electric/magnetic solid deformation measurement, etc., can solve the problems of insufficient self-repair performance of sensors, internal damage of flexible materials, and decreased sensitivity of sensors. Achieve the effect of uniform compressive stress distribution, uniform tensile deformation and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

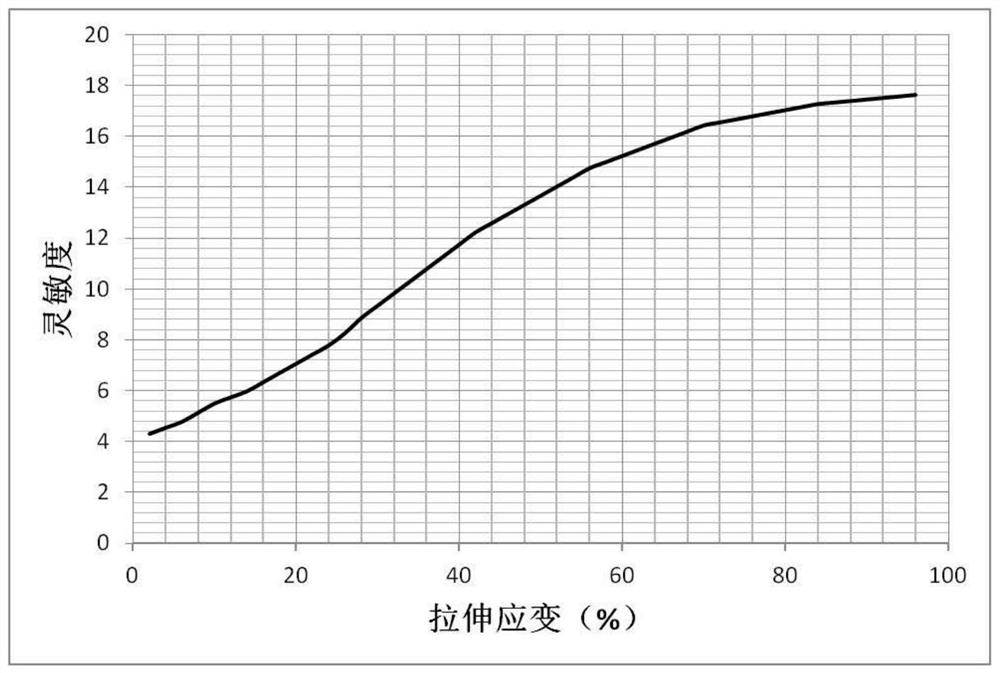

Embodiment 1

[0026] A three-dimensional network graphene-based tensile strain sensor, its preparation method comprising:

[0027] (1) Preparation of soft gel precursor:

[0028] Dissolve 5g of urea and 8g of formaldehyde in 50ml of water to obtain mixed solution A; dissolve vinyl polydimethylsiloxane, N-isopropylacrylamide, and vinylpyrrolidone in the solvent respectively to obtain a mass volume concentration of 8g / 100ml The solutions B, C, and D were mixed and reacted with the solutions A, B, C, and D according to the volume ratio of 1:2:1:1 to obtain the reaction product M, which is the soft gel precursor.

[0029] (2) Preparation of graphene with 3D network structure:

[0030] The nickel foam was cleaned sequentially with alcohol, acetone, and deionized water, and then dried with nitrogen gas. As a template for growing graphene with a 3D network structure, the cleaned and dried nickel foam was transferred to a chemical vapor deposition device, and the nickel foam was sprayed with metha...

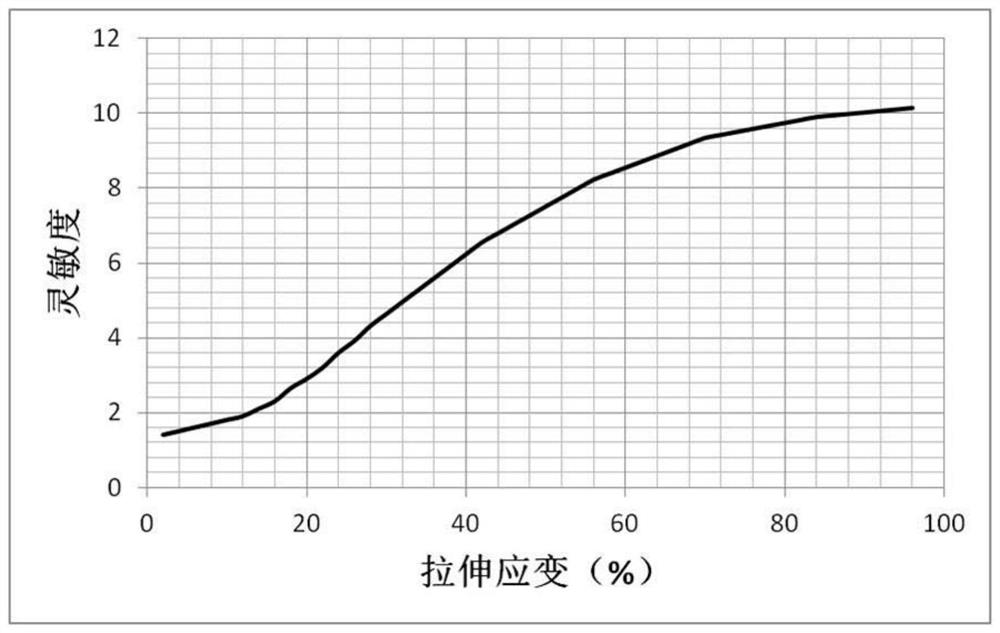

Embodiment 2

[0037] A three-dimensional network graphene-based tensile strain sensor, its preparation method comprising:

[0038] (1) Preparation of soft gel precursor:

[0039] Dissolve 3g of urea and 7g of formaldehyde in 50ml of water to obtain a mixed solution A; dissolve vinyl polydimethylsiloxane, N-isopropylacrylamide, and vinylpyrrolidone in the solvent respectively to obtain a mass volume concentration of 6g / 100ml The solutions B, C, and D were mixed and reacted with the solutions A, B, C, and D according to the volume ratio of 1:2:1:1 to obtain the reaction product M, which is the soft gel precursor.

[0040] (2) Preparation of graphene with 3D network structure:

[0041] The nickel foam was cleaned sequentially with alcohol, acetone, and deionized water, and then dried with nitrogen gas. As a template for growing graphene with a 3D network structure, the cleaned and dried nickel foam was transferred to a chemical vapor deposition device, and the nickel foam was sprayed with met...

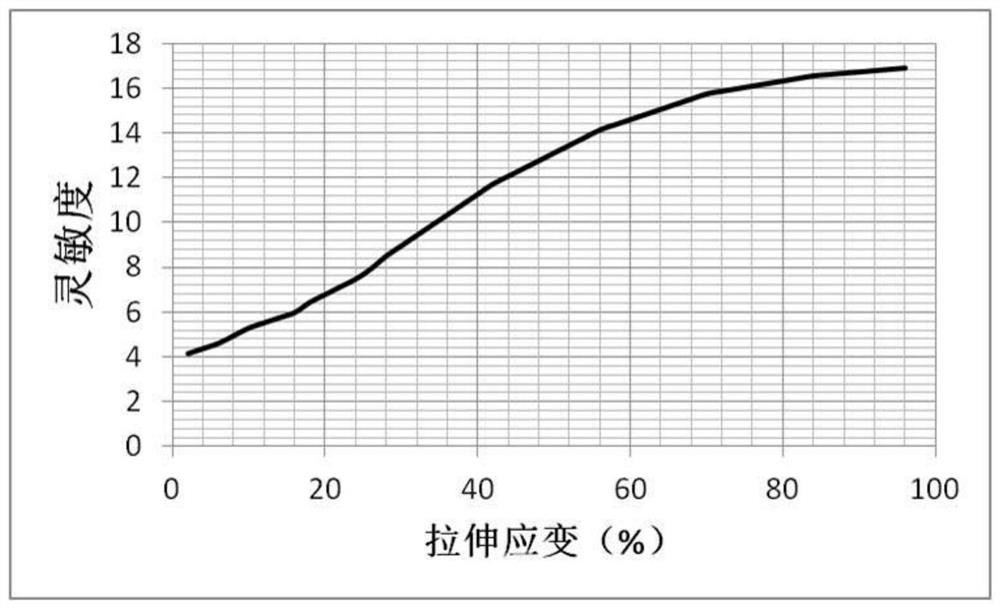

Embodiment 3

[0048] A three-dimensional network graphene-based tensile strain sensor, its preparation method comprising:

[0049] (1) Preparation of soft gel precursor:

[0050] Dissolve 3g of urea and 10g of formaldehyde in 50ml of water to obtain a mixed solution A; dissolve vinyl polydimethylsiloxane, N-isopropylacrylamide, and vinylpyrrolidone in the solvent respectively to obtain a mass volume concentration of 10g / 100ml The solutions B, C, and D were mixed and reacted with the solutions A, B, C, and D according to the volume ratio of 1:2:1:1 to obtain the reaction product M, which is the soft gel precursor.

[0051] (2) Preparation of graphene with 3D network structure:

[0052] The nickel foam was cleaned sequentially with alcohol, acetone, and deionized water, and then dried with nitrogen gas. As a template for growing graphene with a 3D network structure, the cleaned and dried nickel foam was transferred to a chemical vapor deposition device, and the nickel foam was sprayed with m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com