Anti-atomization raw material transportation robot for chemical production

A chemical production and anti-fogging technology, applied in the field of robotics, can solve problems such as physical harm to workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

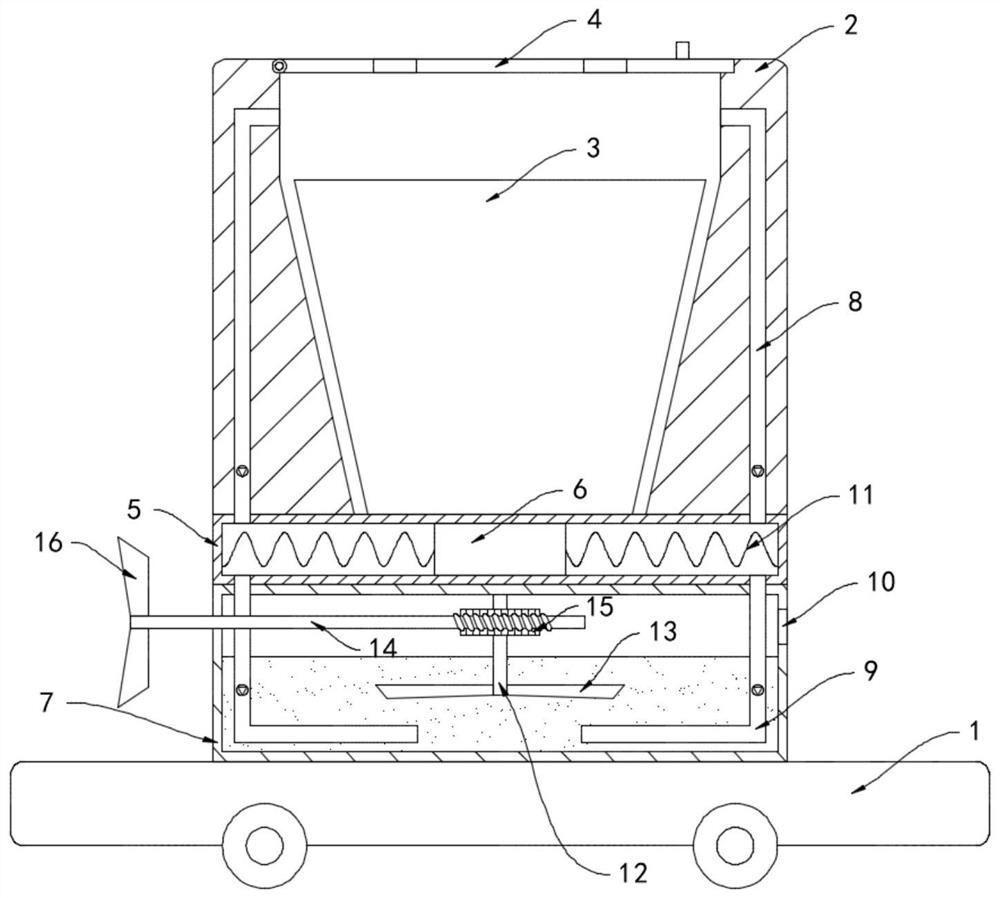

[0018] like figure 1 As shown, an anti-atomization raw material transportation robot for chemical production includes a base 1 and a heat preservation cylinder 2. The heat preservation cylinder 2 is provided with a groove in the shape of a round table, and a liquid holding bucket 3 is arranged in the groove. The upper end of 2 is hinged with an upper cover 4, and a through hole is provided in the upper cover 4. A negative pressure tube 5 arranged horizontally is installed on the bottom of the heat preservation tube 2, and a slider 6 is sealed and slidably connected in the negative pressure tube 5, and the slider 6 passes through The spring 11 is fixedly connected to the inner side wall of the negative pressure pipe 5, the lower end of the negative pressure pipe 5 is fixedly installed with a defogging box 7, and both ends of the negative pressure pipe 5 are fixedly connected with a one-way suction pipe 8 and a one-way exhaust pipe 9. The upper end of the one-way suction pipe 8 ...

Embodiment 2

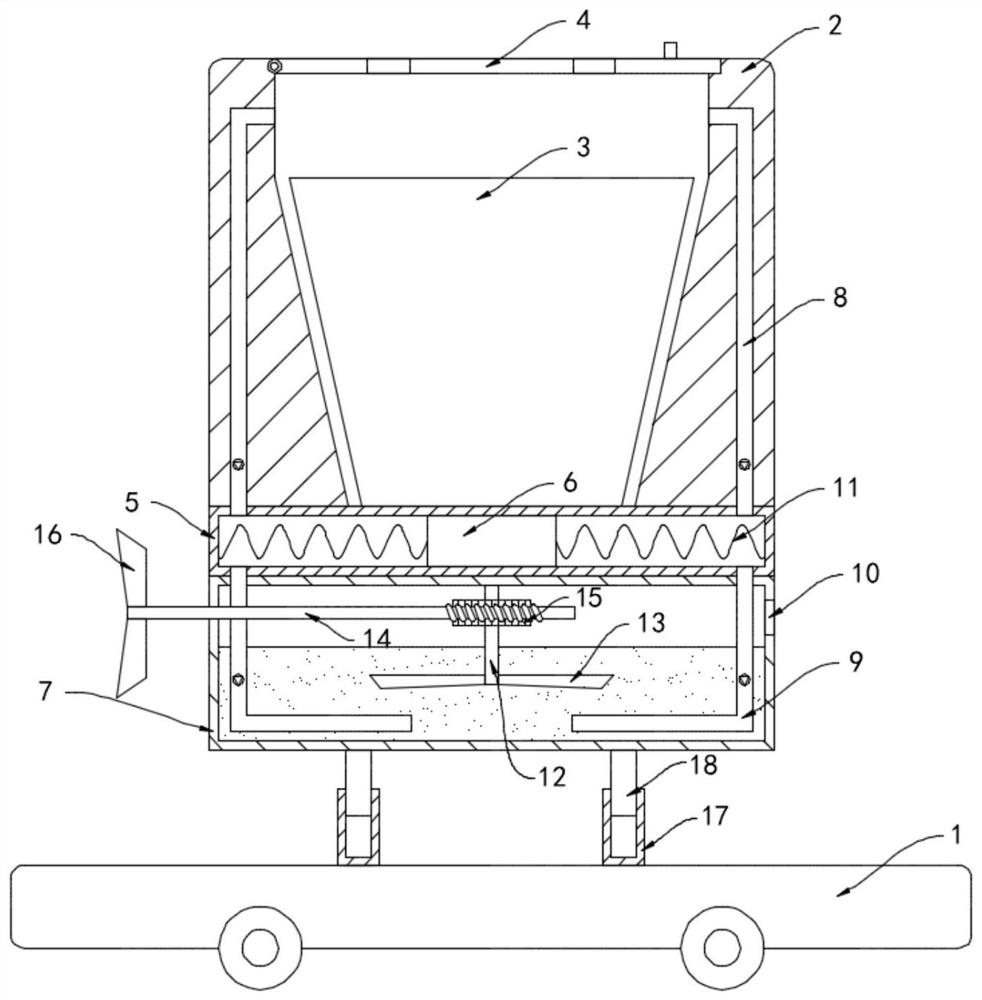

[0023] like figure 2 As shown, the difference between this embodiment and Embodiment 1 is that: the upper surface of the base 1 is fixedly connected with a sleeve 17, and a lifting rod 18 is sealed and slid inside the sleeve 17, and the upper end of the lifting rod 18 is fixed to the defogging box 7 To connect, the sleeve 17 is filled with thermal expansion and contraction medium, and the thermal expansion and contraction medium is one or more of kerosene, mercury and methylene chloride.

[0024] In this embodiment, when the transport robot is driving on a bumpy road section, shaking repeatedly causes a large amount of acid solution to volatilize and atomize, then the acid solution and the alkaline solution undergo neutralization reactions in the demister box 7, generating a large amount of heat. Conducted to the sleeve 17 through the lifting rod 18, the thermal expansion and contraction medium expands when the temperature rises, pushing the lifting rod 18 to move upward, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com