Manufacturing method of high-strength anti-aging cable protection pipe

A technology for cable protection tubes and manufacturing methods, which is applied to chemical instruments and methods, cleaning methods and appliances, electrical components, etc., can solve the problems of inability to mass-produce rapidly and have no manufacturing methods, and achieve good use strength and anti-aging performance. good protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

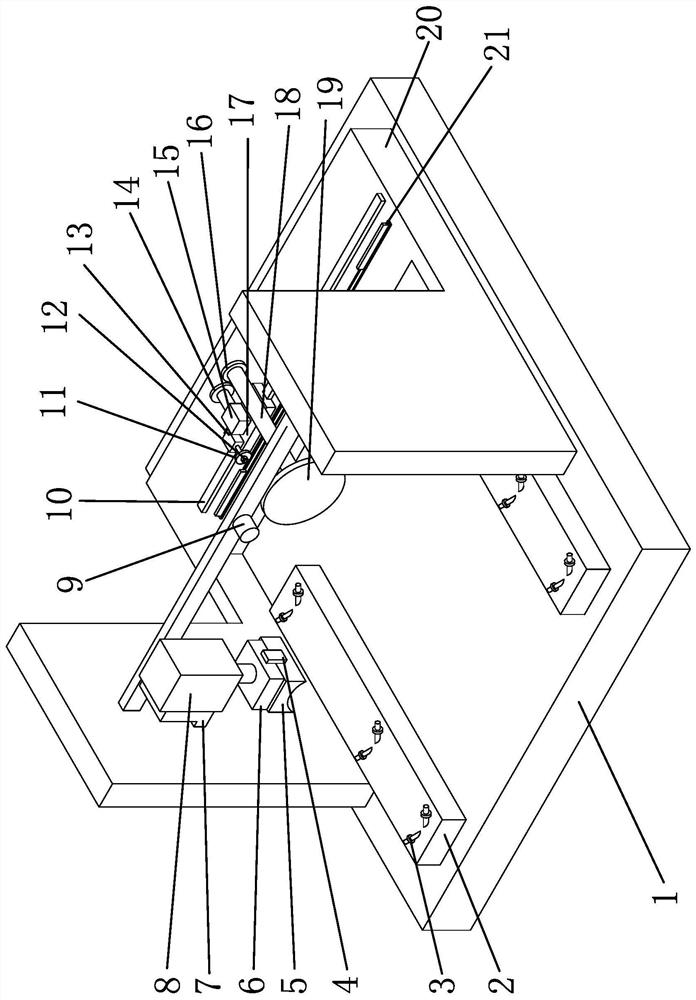

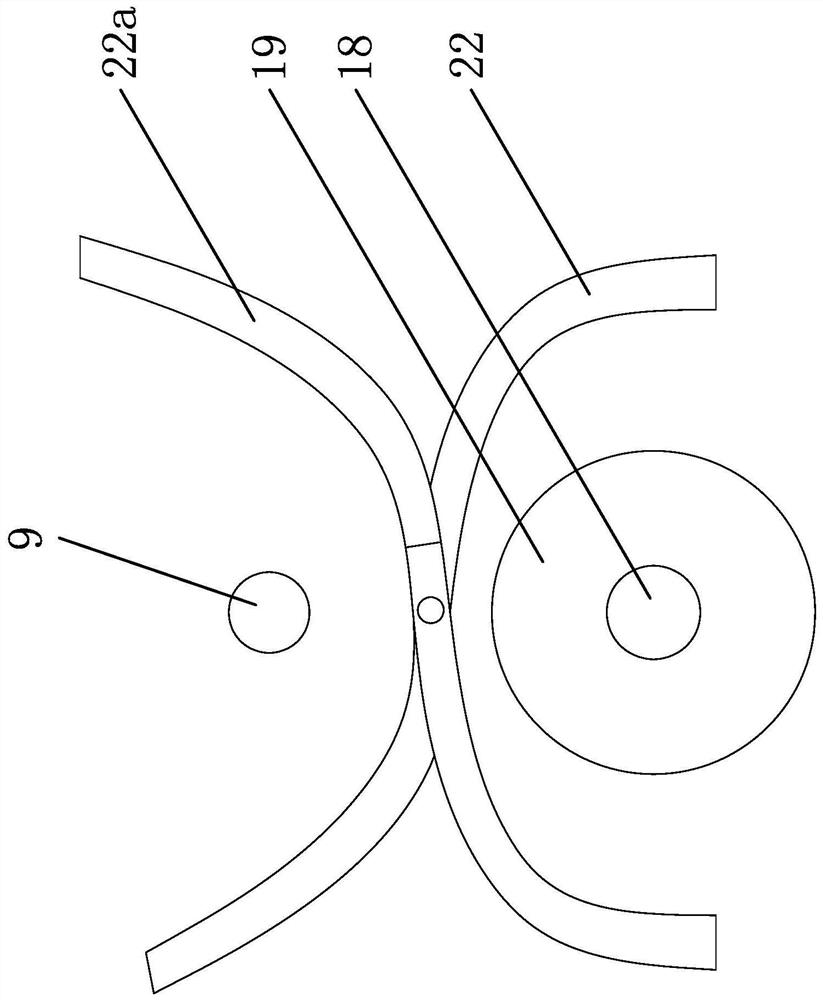

[0064] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

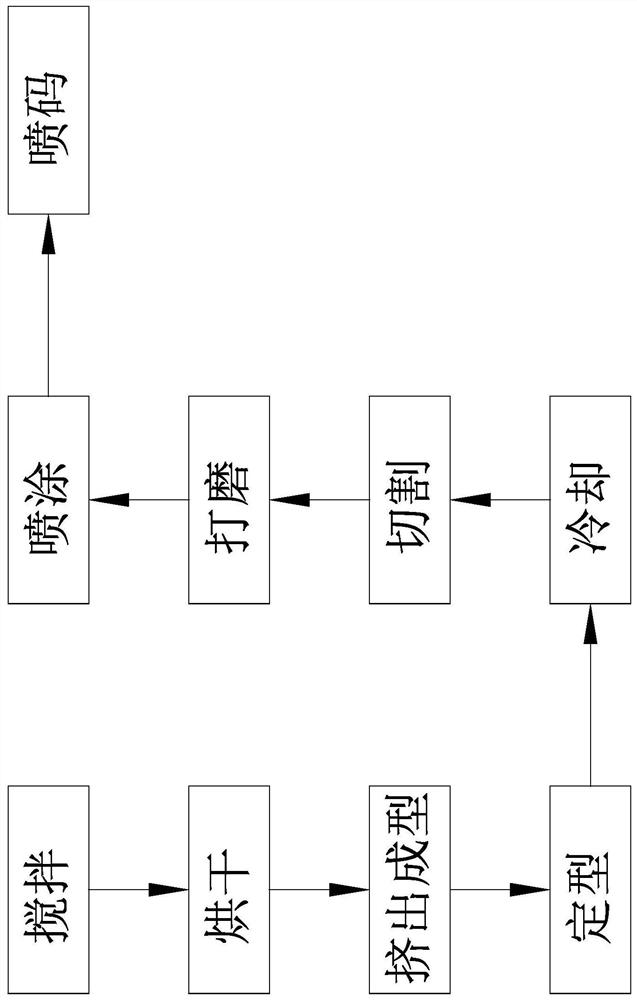

[0065] like Figure 1-Figure 10 As shown, the manufacturing method of the high-strength aging-resistant cable protection tube includes the following steps:

[0066] a. Stirring: by weight, weigh 100 parts of high-density polyethylene resin, 0.8-2.2 parts of antioxidant, 1-4 parts of lubricant, 0-40 parts of filler, 6-20 parts of plasticizer, stabilize Put 0.5-1.5 parts of the agent and 4-8 parts of the color masterbatch into the mixer for stirring treatment to obtain the mixture: in this embodiment, weigh 100 parts of high-density polyethylene resin, 1.2 parts of antioxidant 1 part, 3 parts of lubricant, 15 parts of filler, 9 parts of plasticizer, 1 part of stabilizer and 5 parts of color masterbatch are put into the mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com