Cylindrical part inner and outer ring grinding equipment

A technology of inner and outer rings and cylinders, which is applied in the field of parts processing, can solve the problems of poor practicability, small scope of application, and difficulty in meeting different requirements for grinding cylindrical parts, so as to achieve good grinding operations and expand the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

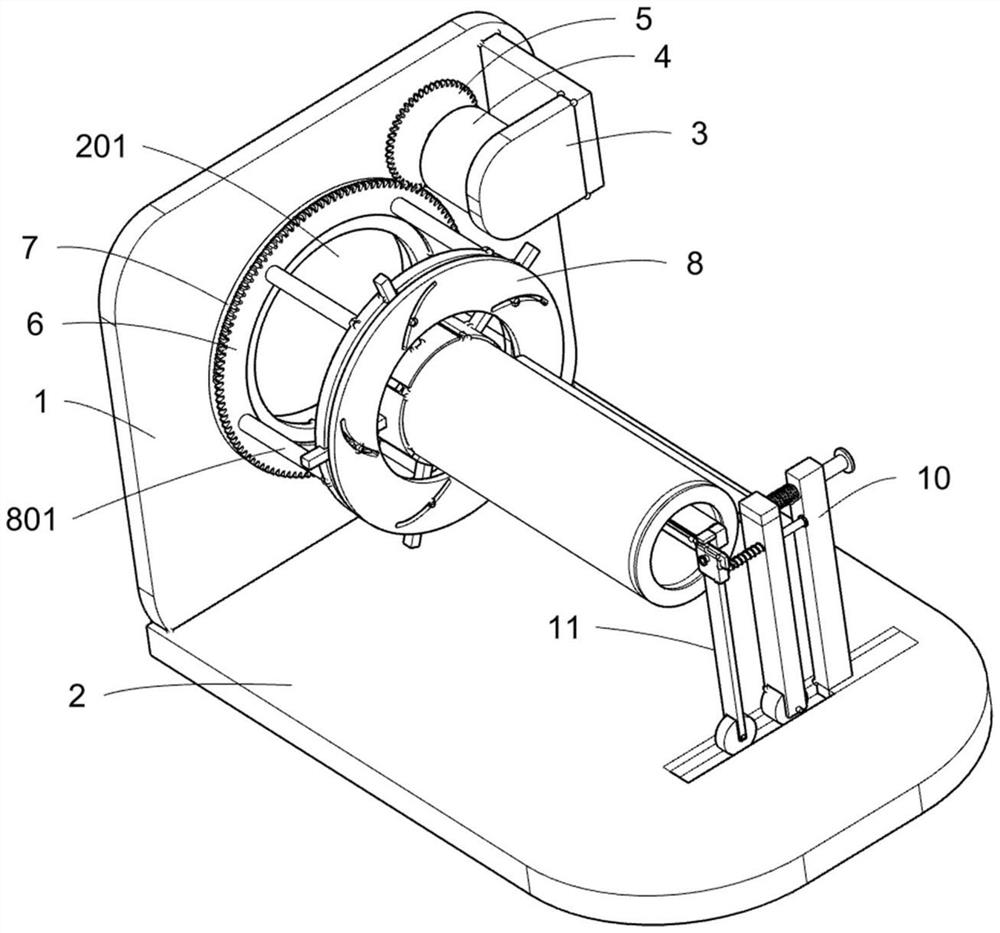

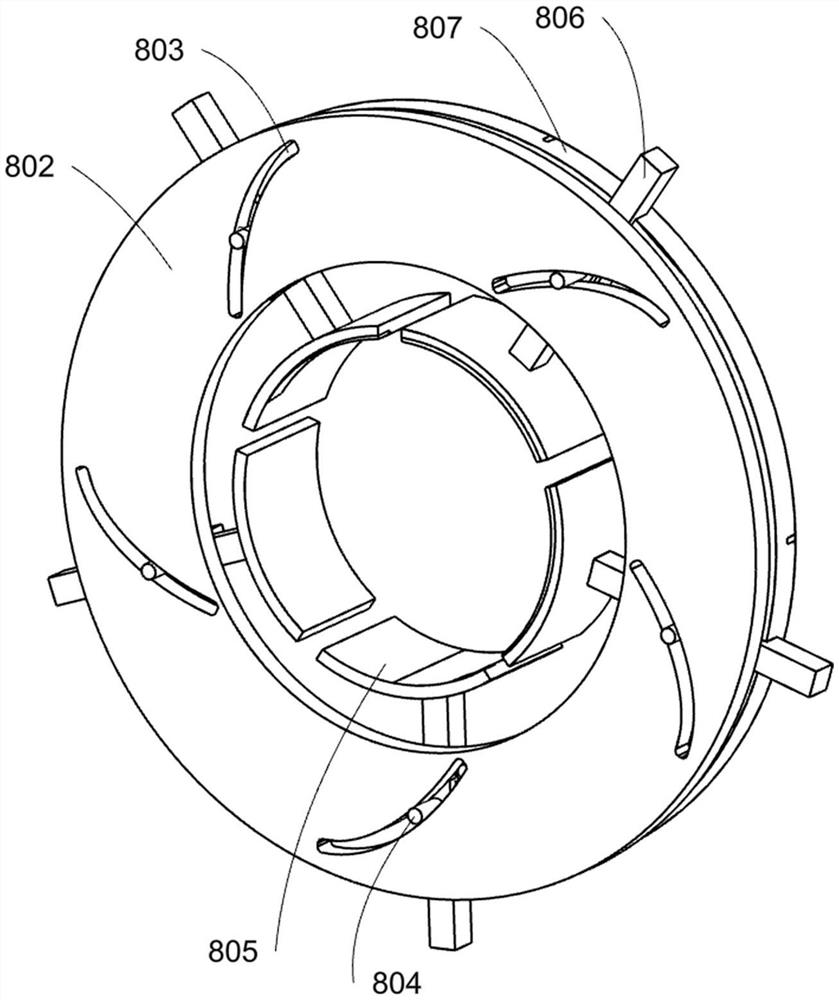

[0025] A kind of grinding equipment for the inner and outer rings of cylindrical parts, such as Figure 1-7 As shown, it includes a vertical plate 1, a horizontal plate 2, a machine plate 3, a rotating motor 4, a pinion 5, a large gear 6, a rotating disk 7, a fixing mechanism 8, an outer ring grinding mechanism 10 and an inner ring grinding mechanism 11, The horizontal plate 2 is fixed on the lower end of the vertical plate 1, and a large through hole 201 is provided on the vertical plate 1, and the machine plate 3 is fixed on one side of the vertical plate 1 and is located above the horizontal plate 2. , the rotating motor 4 is fixed on the machine plate 3, the pinion 5 is arranged on the output shaft of the rotating motor 4 through the rotating shaft and is close to the vertical plate 1, and the rotating disk 7 is rotatably arranged in the large through hole 201 Inside, the large gear 6 is fixed on one side of the rotating disk 7 and meshes with the pinion 5, the fixing mech...

Embodiment 2

[0033] On the basis of Example 1, such as Figure 6-7 Described, also include chute block 117 and big screw rod 118, described chute block 117 is fixedly arranged on the upper end of the second movable support 112 and one end of the second cylinder movable rod 113 and a side of chute block 117 are fixed. Then, the connecting plate 116 is slidably located in the chute block 117, and a threaded hole 119 is provided on the chute block 117, and the large screw 118 is screwed in the threaded hole 119 and one end of the large screw 118 is connected to the connecting plate. 116, and the large screw 118 is used to adjust the position of the connecting plate 116.

[0034] A scale 120 is also included, and the scale 120 for measuring cylindrical parts is fixed on the upper side of the connecting plate 116 .

[0035] In actual use, some special cylindrical parts are composed of hollow parts and solid parts. In order to be able to grind the inner and outer rings of such cylindrical parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com