High-thermal-conductivity uranium dioxide single crystal composite fuel pellet and preparation method thereof

A composite fuel, uranium dioxide technology, applied in the field of nuclear power, can solve the problems of containment and unfavorable fission products, and achieve the effect of offsetting self-blocking and loss, shortening the cycle of research and development, and reducing risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

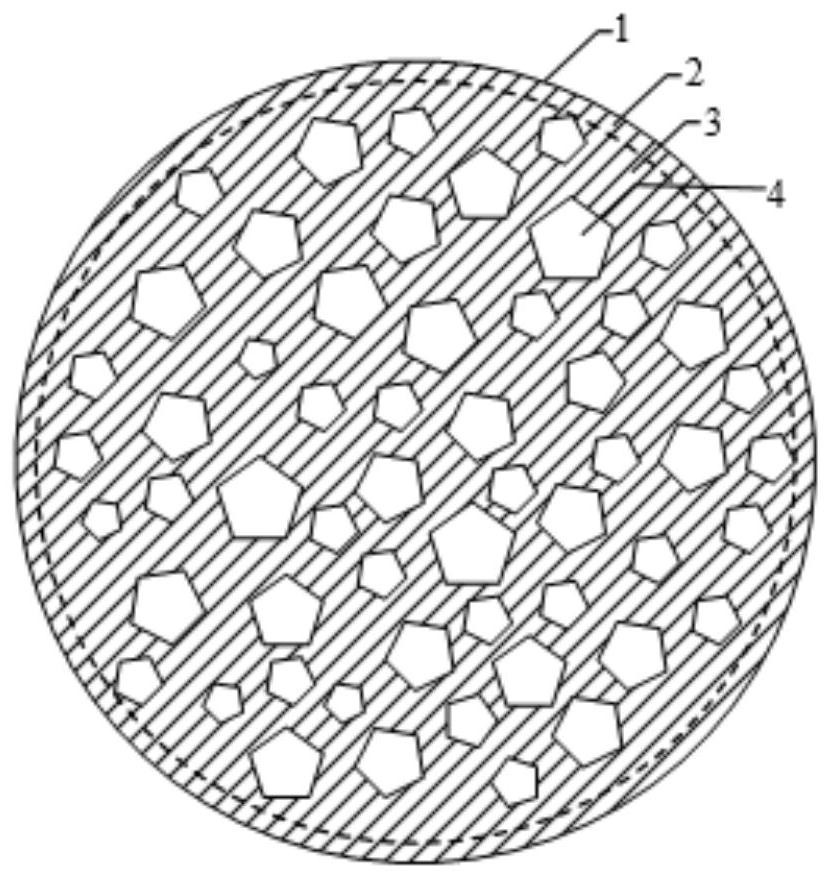

[0023] figure 2 As shown, a high thermal conductivity uranium dioxide single crystal composite fuel pellet, the pellet is UO 2 The single crystal is a fuel particle, and the fuel particle uses SiC powder as a connection medium, and the outer surface of the fuel particle and the connection medium is wrapped with a fuel-free area.

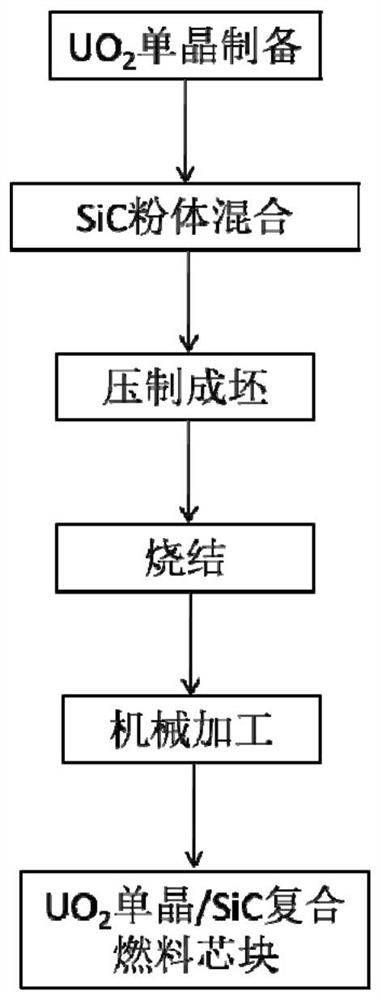

[0024] image 3 shown, using UO 2 The single crystal is used as the dispersed phase, and the second phase of SiC is used as the connecting medium. Using the mechanical method, the UO 2 Mix single crystal and SiC powder evenly, add Al 2 o 3 Powder, etc. are used as sintering aids, and pressed into green bodies. Then, the green body was sintered at 1800°C by a pressureless sintering process, and a columnar composite fuel pellet with a dish-shaped depression at the end and chamfered edges was prepared by machining.

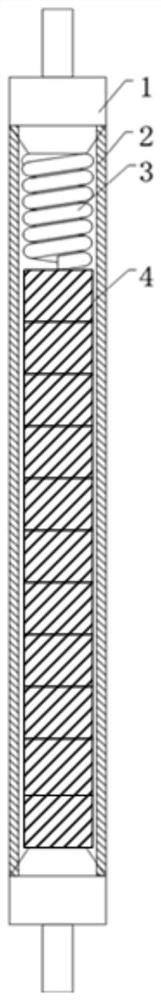

[0025] Figure 4 for the adoption of UO 2 The fuel element of single crystal / SiC composite fuel pellets, the cladding material i...

Embodiment 2

[0027] The difference between this embodiment and the first embodiment is that Zr metal powder is used as the connection medium, and no sintering aid is added. The sintering temperature is 1600°C.

[0028] The above-mentioned high thermal conductivity composite fuel pellets of the present invention are exemplified as follows:

[0029] 1. In composite fuel pellets, UO 2 Single crystal accounts for 80% of the total volume, and SiC accounts for 20% of the total volume. The thermal conductivity of the composite fuel pellet at 1200 °C is about 5.2 W m -1 ·K -1 .

[0030] 2. In composite fuel pellets, UO 2 Single crystal accounts for 50% of the total volume, and SiC accounts for 50% of the total volume. The thermal conductivity of the composite fuel pellet at 1200 °C is about 10.9 W m -1 ·K -1 .

[0031] 3. Among composite fuel pellets, UO 2 Single crystal accounts for 80% of the total volume, and Zr accounts for 20% of the total volume. The thermal conductivity of the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductance | aaaaa | aaaaa |

| thermal conductance | aaaaa | aaaaa |

| thermal conductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com