Fault detection method, heat pump heating equipment, fault detection device and storage medium

A fault detection and fault technology, applied in the field of heat pump heating equipment, can solve problems such as continuous operation of compressors and potential safety hazards for users of compressor relays, and achieve the effect of improving the safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

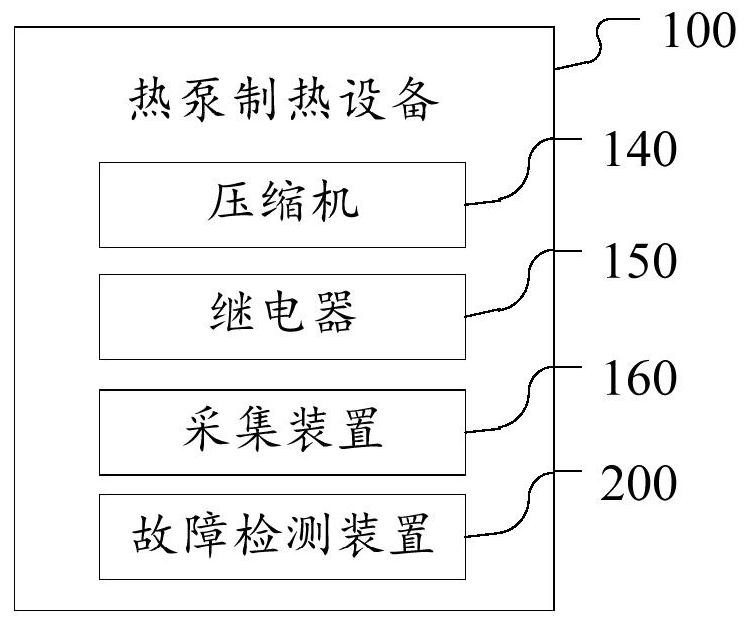

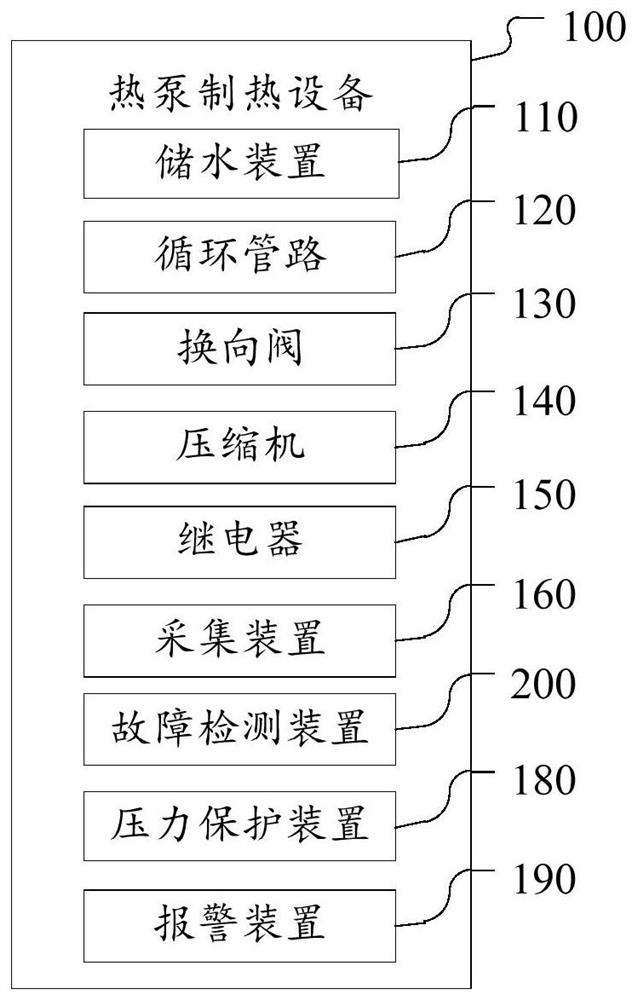

[0064] Such as Figure 4 As shown, this embodiment provides a fault detection method for controlling the heat pump heating equipment 100 according to any embodiment of the present invention. The fault detection method includes:

[0065] Step S102, the fault detection device outputs a closing signal to the relay of the compressor;

[0066] Step S104, the collecting device collects the operating parameters of the heat pump heating equipment;

[0067] Step S106, the fault detection device detects the fault of the relay according to the operating parameters.

[0068] The fault detection method in this embodiment is specifically: after the fault detection device 200 outputs a shutdown signal to the compressor 140, the acquisition device 160 starts to collect the operating parameters of the heat pump heating equipment 100, and the fault detection device 200 detects whether the relay 150 exists according to the operating parameters Fault. Wherein, when the detection result of the ...

Embodiment 2

[0072] Such as Figure 5 with Image 6 As shown, this embodiment provides a fault detection method. In addition to the technical features of the foregoing embodiments, this embodiment further includes the following technical features.

[0073] The operating parameters include the water temperature of the water storage device, and the fault detection device detects the fault of the relay according to the operating parameters, specifically including:

[0074] Step S202, based on the fact that the water temperature is greater than or equal to the first target water temperature and the temperature difference between the water temperature and the first target water temperature is greater than or equal to the first temperature difference threshold, the fault detection device determines that there is a fault in the relay; or

[0075] Step S302, based on the fact that the water temperature is less than the first target water temperature, or based on the fact that the water temperatur...

Embodiment 3

[0084] Such as Figure 7 with Figure 8 As shown, this embodiment provides a fault detection method. In addition to the technical features of any of the above embodiments, this embodiment further includes the following technical features.

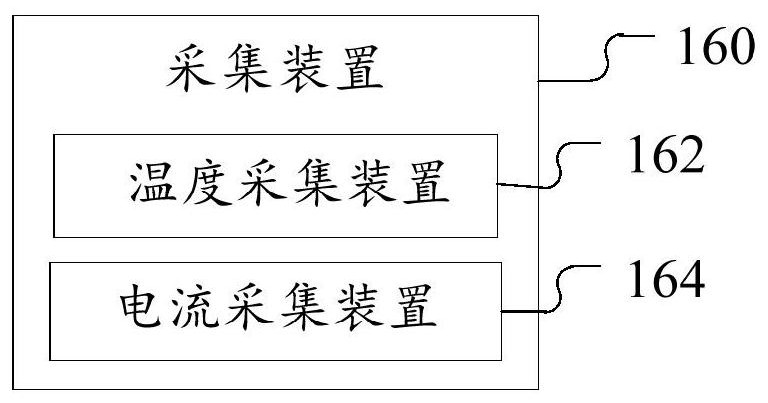

[0085] The operating parameters include the current of the compressor, and the fault detection device detects the fault of the relay according to the operating parameters, specifically including:

[0086]Step S402, based on the fact that the current is greater than or equal to the current threshold, the fault detection device determines that there is a fault in the relay; or

[0087] Step S502, based on the fact that the current is less than the current threshold, the fault detection device determines that the relay is normal.

[0088] In this embodiment, the current of the compressor 140 can be detected and collected by the current collection device 164 . The current collection device 164 can specifically be a current sampling resistor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com