Big bearing-type stranded rope machine and automation control technology thereof

A stranding machine and bearing technology, applied in the field of large-bearing stranding machine and its automation control, can solve the problems of wire brittleness, influence, and low degree of automation of stranding equipment, avoid or reduce waste, and ensure product quality. , the effect of simple control circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing, the large-bearing type stranding machine of the present invention and automatic control technology are described in further detail:

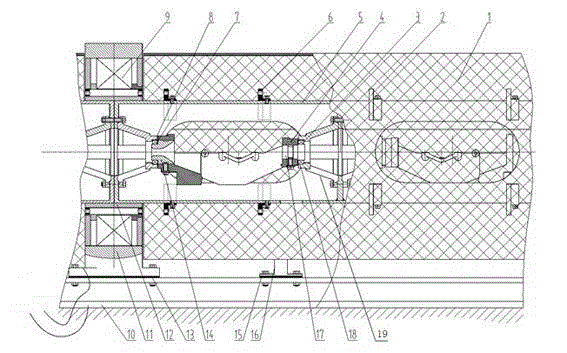

[0012] figure 1 Among them, the large bearing type stranding machine of the present invention is mainly composed of a safety cover 1, a wire passing mold base 2, a frame blue bearing I3, a frame blue 4, a cylinder body 5, a ceramic wire passing die 6, a frame blue bearing II7, and an insulating material 8 , cylinder large bearing 9, base bar 10, cylinder large bearing seat 11, cylinder large bearing bush 12, insulating material 13, horn shaft 14, insulating material 15, safety cover support seat 16, small shaft 17, insulating material 18 and sand frame 19; the ceramic wire passing mold 6 is set in the wire passing mold base 2, and the insulating materials 8 and 18 are set in the contact between the frame blue bearing I3 and the frame blue bearing II7 at the two ends of each frame 4 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com