Threaded wellhead seal inspection pressure-test load determination method, storage medium and equipment

A determination method and sealing detection technology, applied in drilling equipment, sealing/package, measurement, etc., can solve problems such as thread leakage, and achieve the effect of ensuring safe and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

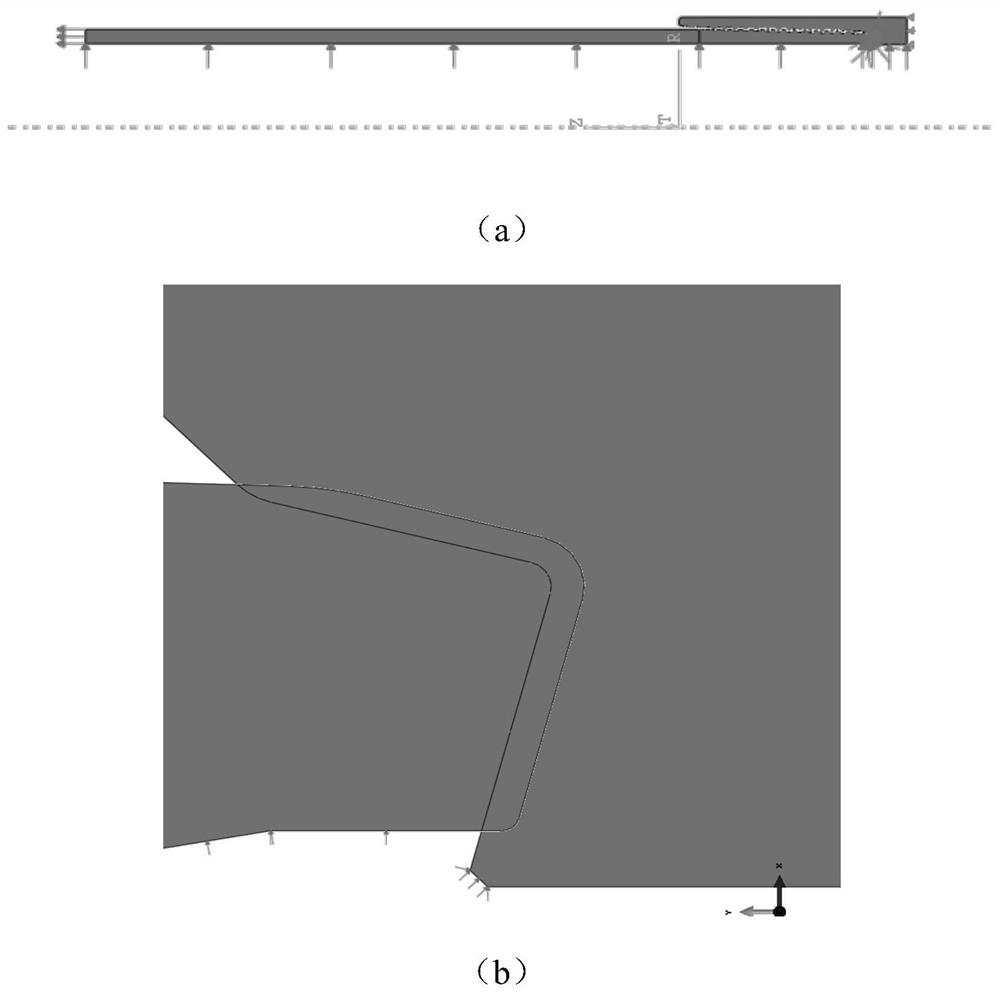

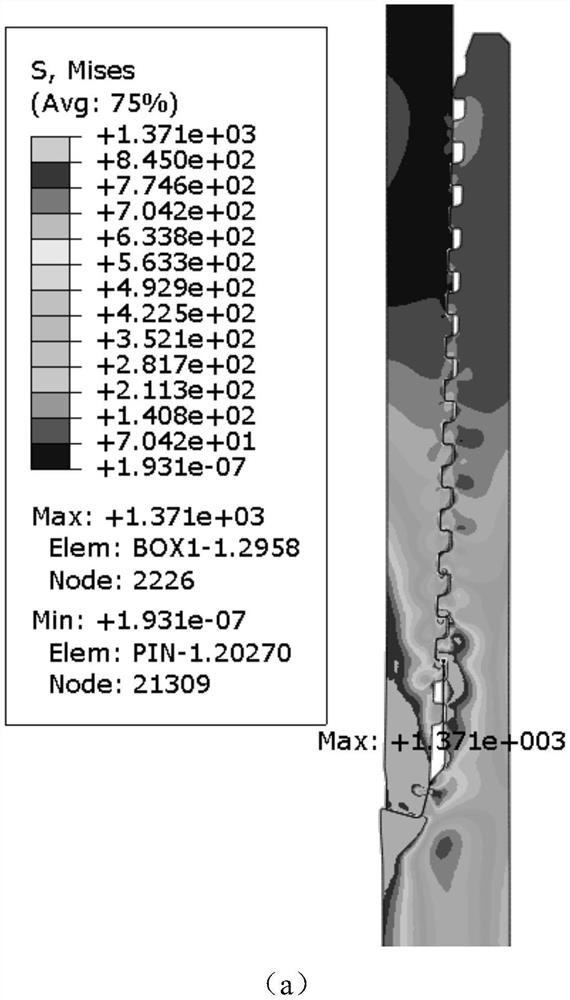

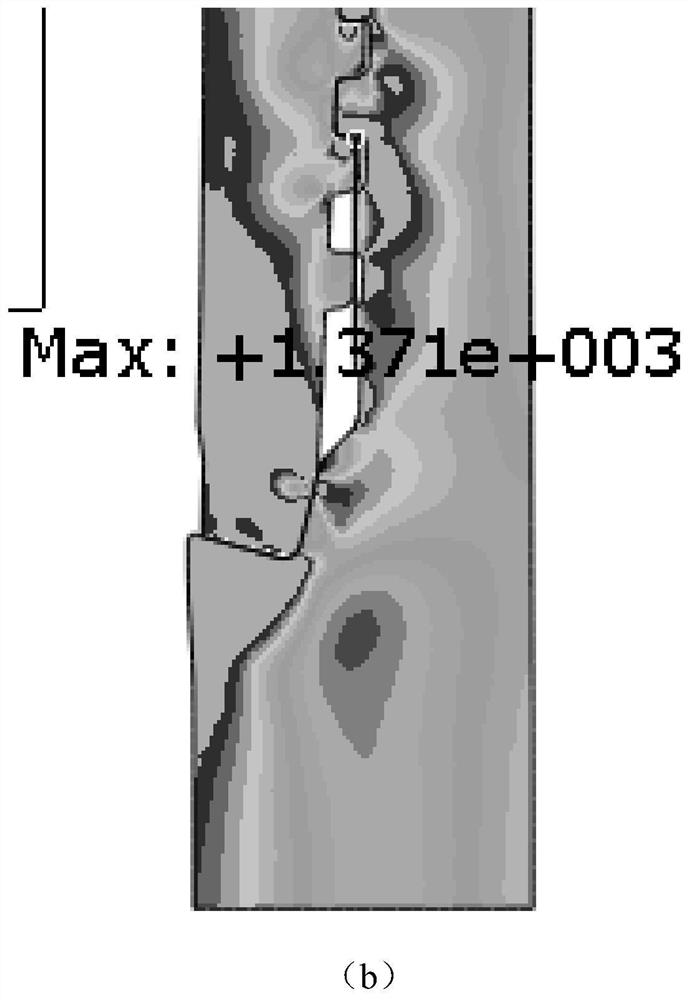

[0039] The invention discloses a method for determining the pressure test load of an oil-casing gas-seal threaded wellhead seal, comprising the following steps:

[0040] S1, analysis sample selection;

[0041] The limit tolerance is used to reflect the main parameters of the thread structure, the pitch diameter of the thread, the taper of the thread, the diameter of the sealing surface and the ellipticity. The limit fit value is selected within the product design tolerance range (see Table 1 and Table 2), so that the thread is screwed up to ensure the seal. The largest surplus, that is, to ensure that the inspected thread products are within the qualified processing tolerance range, and after the three steps of internal pressure loading, load protection, and unloading of the wellhead pressure test, they still have good sealing integrity to ensure the subsequent downhole working conditions of the oil field. safe use.

[0042] The maximum interference fit of the seal within the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com