High-strength bulk cu‑zr‑zn metallic glass and preparation method thereof

A kind of metallic glass, high-strength technology, applied in the field of high-strength bulk Cu-Zr-Zn metallic glass and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

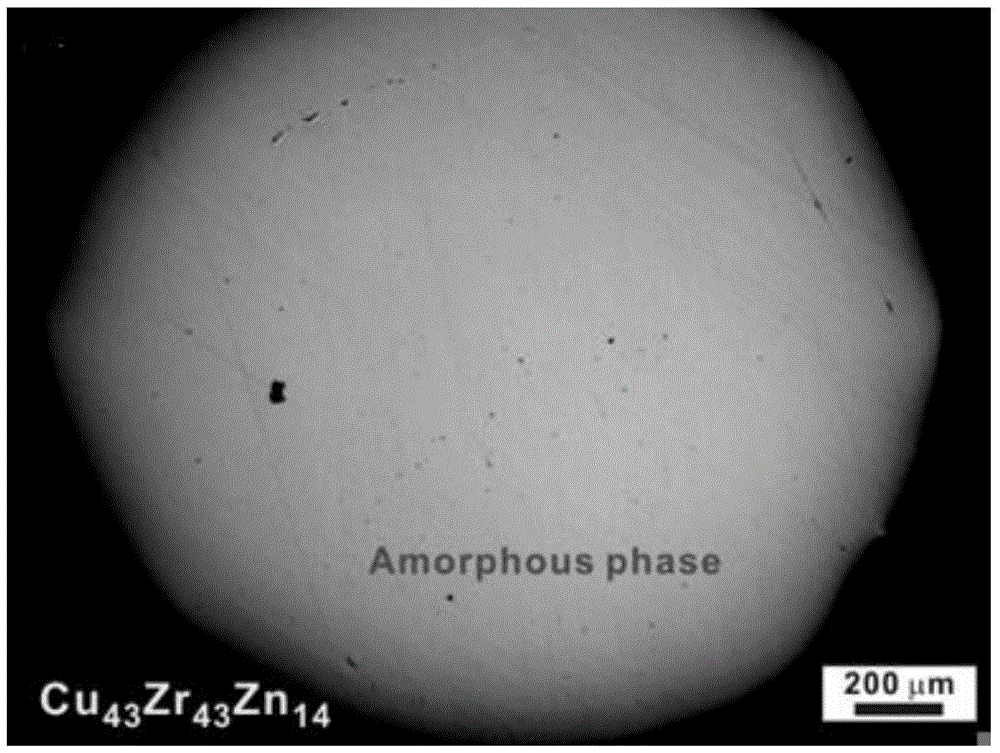

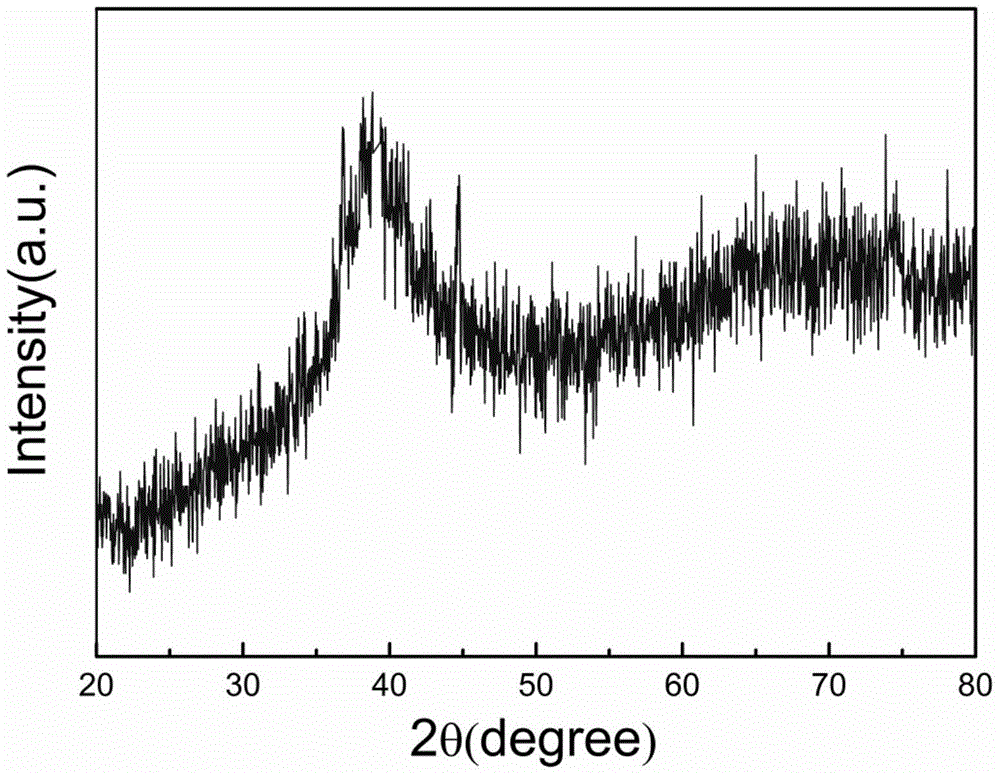

Embodiment 1

[0026] Step 1: Preparation of Cu 43 Zr 43 Zn 14 For a sample of 5g, weigh 1.8047g of pure Cu and 2.5907g of pure Zr, and put them in a well-polished water-cooled crucible;

[0027] Step 2: Evacuate the electric arc furnace to a vacuum of 5×10 -5 Pa, and then backfill Ar gas with a purity of 99.999% to one atmospheric pressure;

[0028] Step 3: Turn on the electric arc furnace and heat up to the melting point of the alloy prepared in step 1, turn the alloy ingot over, re-melt, repeat 3 times to mix the alloy evenly to obtain Cu 50 Zr 50 master alloy;

[0029] Step 4: Remove the surface scale of the master alloy and crush it, weigh 0.6046g of pure Zn, and mix it;

[0030] Step 5: Put it into the quartz test tube in the high-vacuum high-frequency induction melting-blow casting furnace;

[0031] Step 6: Evacuate the high-vacuum high-frequency induction melting-blow casting furnace to a vacuum of 5×10 -5 Pa, and then backfill Ar gas with a purity of 99.999% to one atmospher...

Embodiment 2

[0035] Step 1: Preparation of Cu 43 Zr 43 Zn 14 For a sample of 5g, weigh 1.8047g of pure Cu and 2.5907g of pure Zr, and put them in a well-polished water-cooled crucible;

[0036] Step 2: Evacuate the electric arc furnace to a vacuum of 5×10 -5 Pa, and then backfill Ar gas with a purity of 99.999% to one atmospheric pressure;

[0037] Step 3: Turn on the electric arc furnace and heat up to the melting point of the alloy prepared in step 1, turn the alloy ingot over, re-melt, repeat 4 times to mix the alloy evenly to obtain Cu 50 Zr 50 master alloy;

[0038] Step 4: Remove the surface scale of the master alloy and crush it, weigh 0.6046g of pure Zn, and mix it;

[0039] Step 5: Put it into the quartz test tube in the high-vacuum high-frequency induction melting-blow casting furnace;

[0040] Step 6: Evacuate the high-vacuum high-frequency induction melting-blow casting furnace to a vacuum of 5×10 -5 Pa, and then backfill Ar gas with a purity of 99.999% to one atmospher...

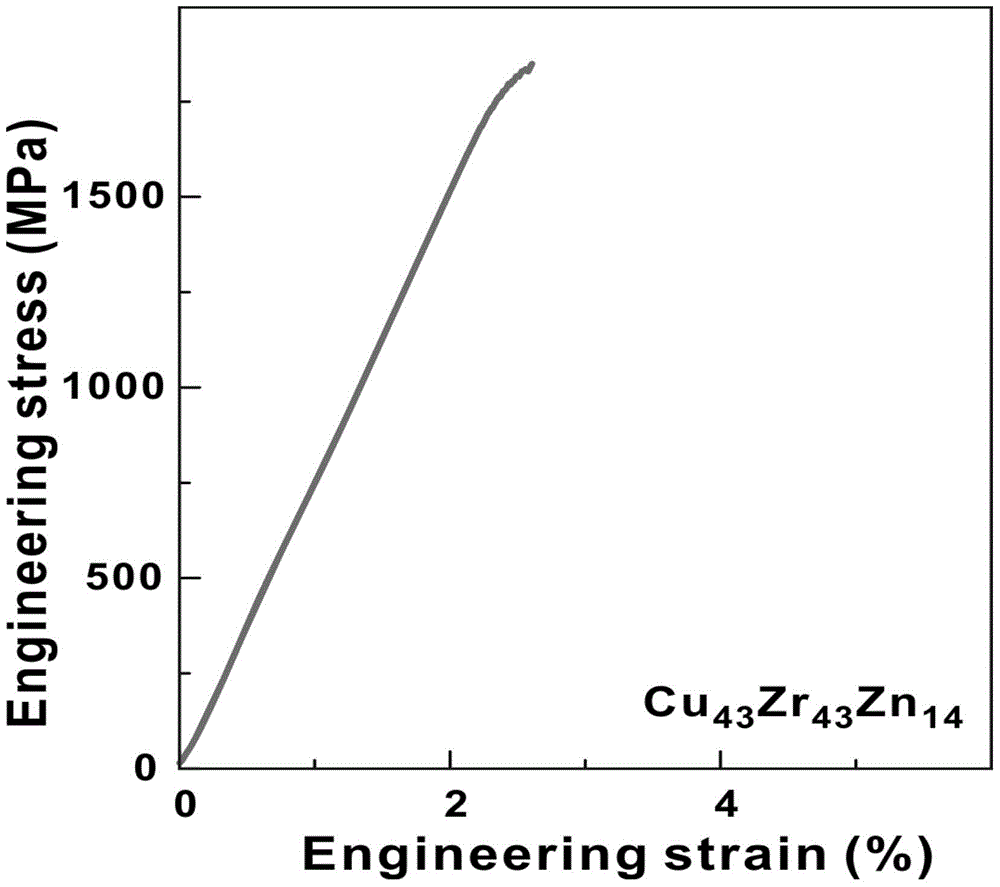

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com