High-performance concrete and preparation method thereof

A high-performance concrete and gel material technology, applied in the field of concrete materials, can solve problems such as insufficient compression resistance, flexural resistance, difficulty in separating free water, and stuck mixing equipment, so as to improve dispersion and dissipation efficiency and prevent increase The effect of tough fiber agglomeration and good viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

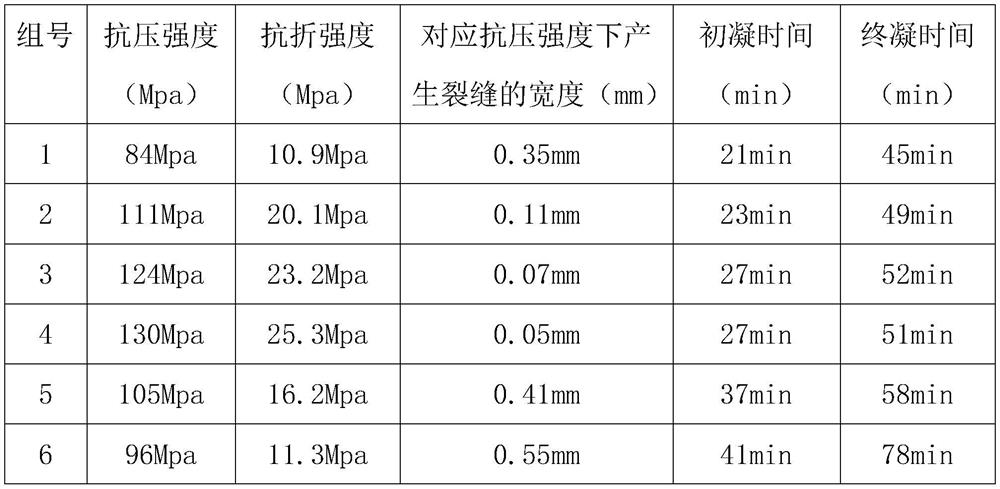

Examples

Embodiment 1

[0033] A high-performance concrete, including gel material, aggregate, admixture, toughening fiber, mixing water, proportioned according to mass fraction, wherein:

[0034] The gel material includes 50-70 parts of Portland cement, 15-25 parts of fly ash, and 15-25 parts of silica fume;

[0035] The aggregate includes 16-19 parts of fine river sand, 4-6 parts of ISO standard sand, and 0.5-1.5 parts of quartz sand;

[0036] The admixture includes polycarboxylate water reducer, hydroxypropyl methylcellulose;

[0037] The toughening fibers include 1-1.5 parts of pva chopped fibers and 0.6-1.5 parts of pp fibers, and the quality of the toughening fibers does not exceed 3% of the mass of the gel material;

[0038] The ratio of the mixing water mass to the gel material mass is less than 0.3.

Embodiment 2

[0040] The technical content described in embodiment 1 is further detailed and supplemented, the Portland cement adopts 52.5 Portland cement, the fly ash adopts first-grade fly ash, and the silica fume adopts nano silica fume;

[0041] Fine river sand adopts freshwater river fine river sand whose particle size range is set between 0.45-0.75mm, and its gradation effect is good, and the ratio of aggregate mass to gel material mass is set between 0.20-0.30;

[0042] The ratio of the mass of the admixture to the mass of the gel material is set between 0.001-0.002;

[0043] The length of pva chopped fiber is set between 6-12mm, and the length of pp fiber is set at 9-12mm;

[0044] Tap water is used for mixing water, and the construction effect of high-performance concrete is the best when the ratio of mixing water mass to gel material mass is set between 0.15-0.25.

Embodiment 3

[0046] A preparation method of high-performance concrete has the following steps:

[0047] S1: Mix Portland cement, fly ash, and silica fume and stir evenly to form a gel material;

[0048] S2: Add a specific amount of mixing water and stir to mix evenly, so that the mixture is in a slurry state;

[0049] S3: Slowly add the toughening fiber several times, and stir evenly to ensure that the toughening fiber is fully dispersed in the gel material;

[0050] S4: Add a specific amount of mixing water to adjust fluidity;

[0051] S5: adding a specific amount of hydroxypropyl methylcellulose to adjust the consistency;

[0052] S6: Add a specific amount of mixing water and a specific amount of aggregate, and stir evenly;

[0053] S7: Add a specific amount of polycarboxylate superplasticizer, stir and mix evenly to produce high-performance concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com