Plate laminating device for green and environment-friendly carton production line

A bonding device, green and environmentally friendly technology, applied in biological packaging, paper/cardboard containers, packaging, etc., can solve problems affecting production efficiency and low efficiency, and achieve the effect of ensuring output efficiency and convenient bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

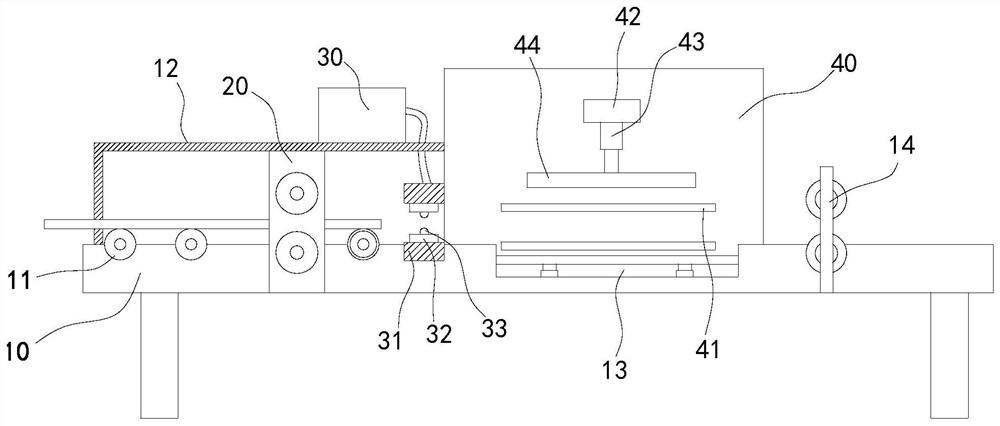

[0026] Such as Figure 1-11 As shown, the present invention provides a board bonding device for a green environmental protection carton production line, including:

[0027] A frame 10, the upper surface of the frame 10 is provided with a conveying roller 11, and the top of the conveying roller 11 is provided with a support frame 12;

[0028] Laminating device, the laminating device is arranged at the middle position of the frame 10, wherein the laminating device includes a box body 40 arranged on the frame 10, and the middle position of the top of the outer wall of the box body 40 is A horizontal plate 42 is provided, a hydraulic cylinder 43 is vertically provided at the bottom of the horizontal plate 42, a pressure plate 44 is provided horizontally at the output end of the hydraulic cylinder 43, a pair of discharge ports 41 are provided at the bottom of the outer wall of the box body 40, The box body 40 is provided with a discharge mechanism, and the discharge mechanism incl...

Embodiment 2

[0033] Such as Figure 1-11 As shown, the present invention provides a board bonding device for a green environmental protection carton production line, including:

[0034] A frame 10, the upper surface of the frame 10 is provided with a conveying roller 11, and the top of the conveying roller 11 is provided with a support frame 12;

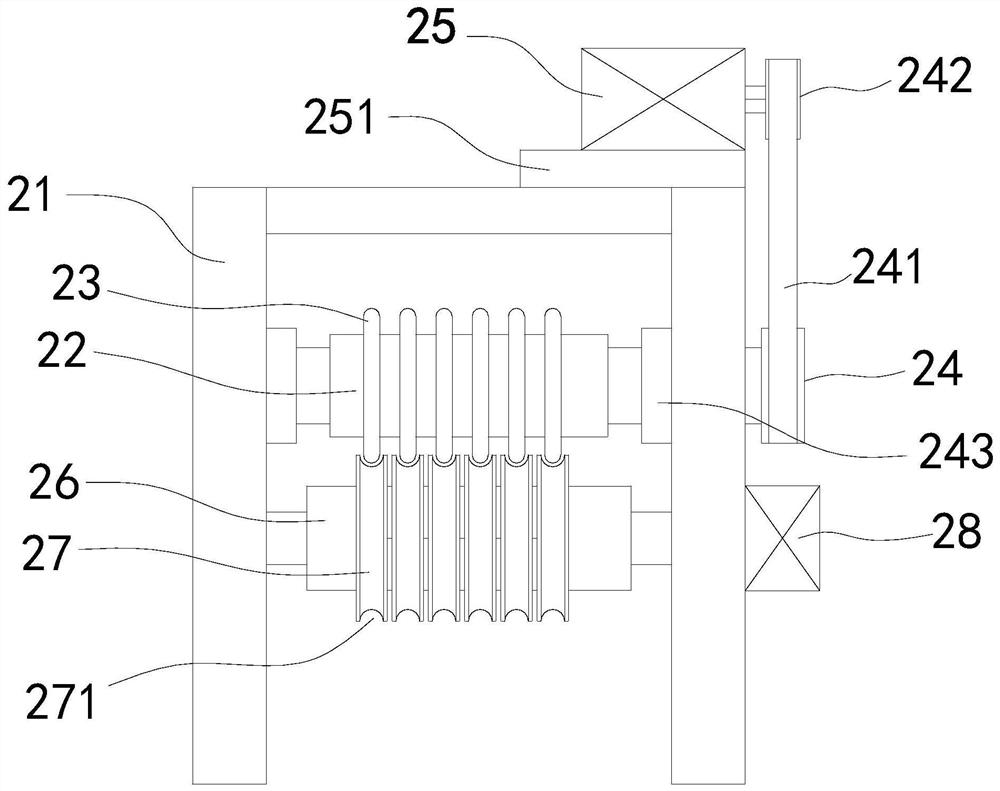

[0035] An indentation device 20, the indentation device 20 includes a fixed frame 21 arranged on the support frame 12, a second roller body 26 is movably arranged between the fixed frame 21, and the second roller body 26 The right end is connected with the second motor 28 arranged on the right end of the fixed frame 21, the surface of the second roller body 26 is provided with a second protruding ring 27, and the outer wall of the second protruding ring 27 is provided with a groove 271, so The top of the second roller body 26 is provided with a movable groove 211 corresponding to the fixed frame 20, and a slider 243 is slidably arranged in the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com