Ultra-high molecular weight polyethylene fiber varicose veins sock and production equipment thereof

A polyethylene fiber and ultra-high polymer technology, applied in electromechanical devices, mixers, electric vehicles, etc., can solve the problems of easy breeding of bacteria, aggravation of disease, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

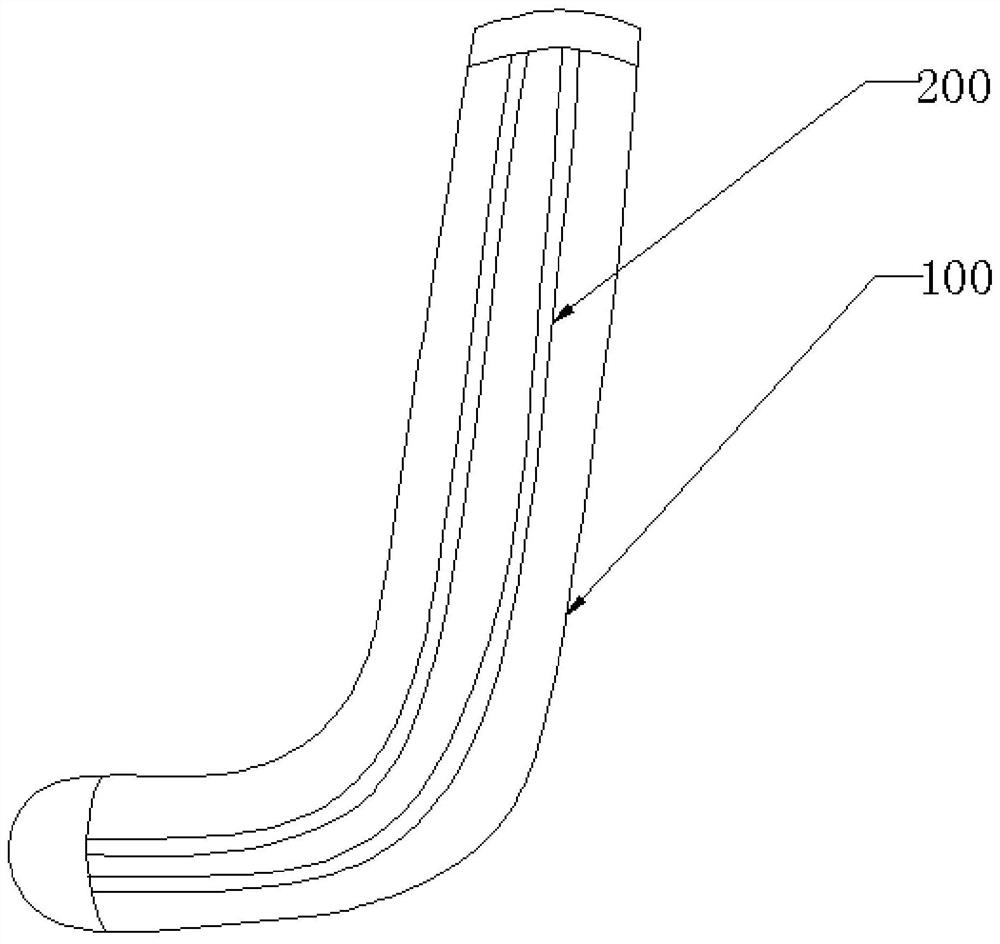

[0039] Such as figure 1 As shown, the present invention discloses a kind of ultra-high molecular weight polyethylene fiber varicose veins socks, including a sock body 100. In a specific embodiment of the invention, the inner layer of the sock body 100 is adhered with nano-antibacterial materials, and the sock body At least two soft magnetic strips 200 parallel to each other are arranged on the outer side of the body 100 along the length direction, and two adjacent soft magnetic strips 200 attract each other.

[0040] By adopting the above-mentioned technical scheme, nano-antibacterial materials are adhered to the inner layer of the sock body 100, and the special nano-antibacterial material is used, which has a good antibacterial effect. The outer side of the sock body 100 is provided with at least two soft magnetic strips parallel to each other along the length direction. 200, two adjacent soft magnetic strips 200 are attracted to each other. When the blood flows from the hear...

Embodiment 2

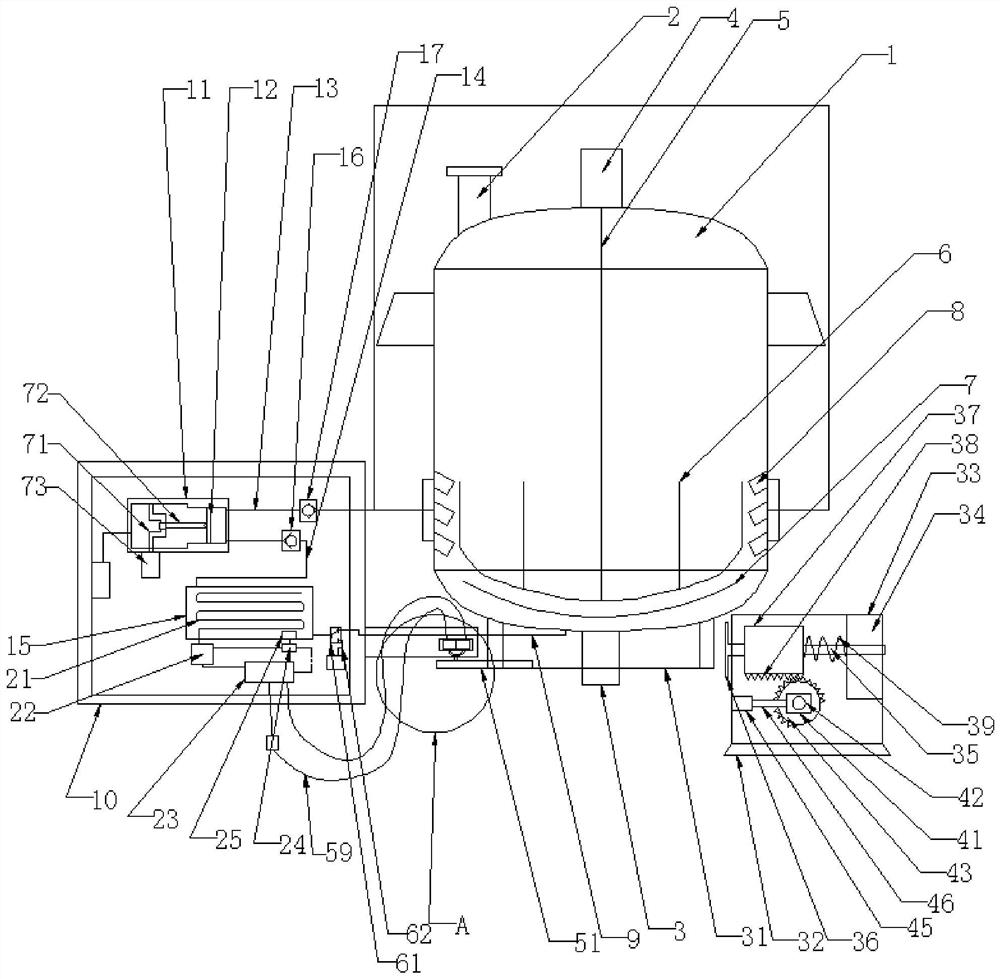

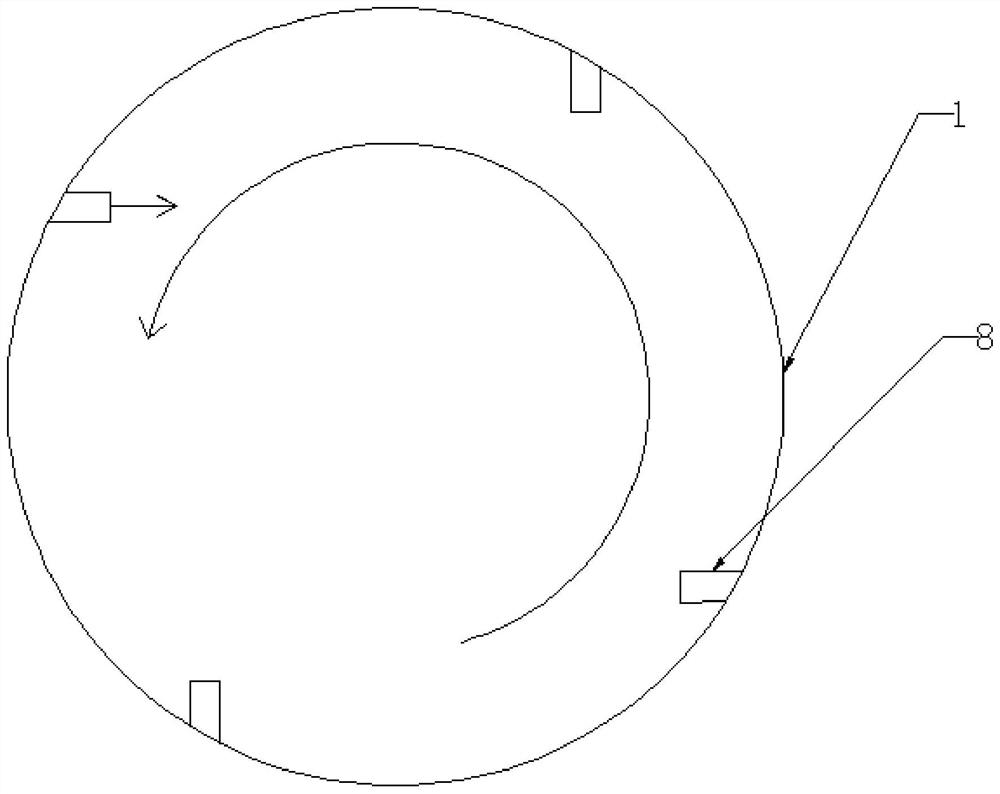

[0048] Such as Figure 2-Figure 4As shown, the present invention also discloses a production equipment for ultra-high molecular polyethylene fiber varicose socks, comprising a reactor body 1, the top of the reactor body 1 is provided with a feed pipe 2, and the bottom of the reactor body 1 is A discharge pipe 3 is provided, and the top of the reactor body 1 is provided with a stirring shaft 5 that extends into the reactor body 1 and is driven by a motor 4. The bottom of the stirring shaft 5 is fixed with a stirring paddle 6, and the reactor body 1 A pressure relief valve is installed on the top. In a specific embodiment of the present invention, the bottom of the reactor body 1 is equipped with a main electric heating tube 7 below the stirring paddle 6, and the reactor body 1 above the main electric heating tube 7 The side wall is fixed with several nozzles 8 spraying towards the obliquely downward direction, and the bottom of the reaction kettle body 1 below the main electric...

Embodiment 3

[0061] Such as Figure 2-Figure 4 As shown, the present invention simultaneously discloses a production method suitable for the production equipment of the above-mentioned ultra-high molecular polyethylene fiber varicose veins socks. In a specific embodiment of the present invention, the following steps are included:

[0062] S1. Feed stirring: The raw material enters the interior of the reactor body 1 through the feed pipe 2, and the main electric heating pipe 7 runs to heat the mixed liquid inside the reactor body 1, and driven by the motor 4, the stirring shaft 5 Rotate to drive the stirring paddle 6 to stir the mixture;

[0063] S2. Circulating heating and stirring: During the stirring process, the rotating shaft 71 at the output end is driven by the rotating motor 73 to rotate. During the rotating process of the rotating shaft 71, the driving rod 72 drives the piston 12 to move back and forth, and the switching valve 61 is now The inlet end and the outlet end are connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com