Method for preparing medical titanium alloy material through laser sintering

A laser sintering, titanium alloy technology, applied in electrolytic coatings, additive processing, surface reaction electrolytic coatings, etc., can solve problems such as adverse effects on implant stability, affecting bone growth rate, biomechanical mismatch, etc. The effect of easy bonding, lower elastic modulus, and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

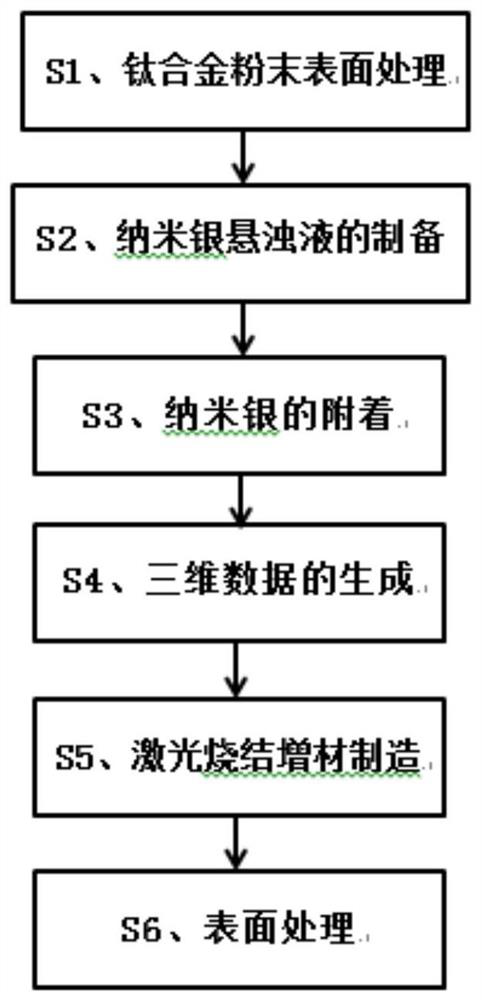

[0028] A method for preparing a medical titanium alloy material by laser sintering, the method comprising the steps of:

[0029] S1. Titanium alloy powder surface treatment: select atomized titanium alloy powder with an average particle size of 20 μm, use inert gas to drive the atomized titanium alloy powder, and hit the spiral mold with an air velocity of 400m / s. The spiral mold adopts a spiral pipe Mold, the inner diameter of the mold is 1cm, and the inner surface of the spiral mold is evenly distributed with carbide protrusions with a triangular cross-section. The width and height of the carbide protrusions are both 70 nanometers, and the mold is ultrasonically vibrated during the impact process , the frequency of ultrasonic vibration is 20kHz, and the amplitude is 2μm. After being processed by a spiral mold, the surface of the atomized titanium alloy powder is cut out of nano-scale pits, and the treated titanium alloy powder is collected for use;

[0030] S2. Preparation o...

Embodiment 2

[0036] A method for preparing a medical titanium alloy material by laser sintering, the method comprising the steps of:

[0037] S1. Titanium alloy powder surface treatment: select atomized titanium alloy powder with an average particle size of 40 μm, use inert gas to drive the atomized titanium alloy powder, and hit the spiral mold with an air velocity of 450m / s. The spiral mold adopts a spiral pipe Mold, the inner diameter of the mold is 1.5cm, and the inner surface of the spiral mold is evenly distributed with carbide protrusions with a triangular cross-section. The width and height of the carbide protrusions are both 75nm, and the mold is ultrasonically vibrated during the impact process. , the ultrasonic vibration frequency is 20kHz, and the amplitude is 3μm. After being processed by a spiral mold, the surface of the atomized titanium alloy powder is cut out of nano-scale grooves, and the processed titanium alloy powder is collected for use;

[0038] S2. Preparation of na...

Embodiment 3

[0044] A method for preparing a medical titanium alloy material by laser sintering, the method comprising the steps of:

[0045] S1. Titanium alloy powder surface treatment: select atomized titanium alloy powder with an average particle size of 60 μm, use inert gas to drive the atomized titanium alloy powder, and hit the spiral mold with an air velocity of 500m / s. The spiral mold adopts a spiral pipe Mold, the inner diameter of the mold is 2cm, and the inner surface of the spiral mold is evenly distributed with carbide protrusions with a triangular cross-section. The width and height of the carbide protrusions are both 80nm. Ultrasonic vibration is performed on the mold during the impact process. The frequency of ultrasonic vibration is 20kHz, and the amplitude is 4μm. After being processed by a spiral mold, the surface of the atomized titanium alloy powder is cut out of nano-scale pits, and the treated titanium alloy powder is collected for later use;

[0046] S2. Preparation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com