High value-added whole-grain food deep processing technology

A high value-added, whole grain technology, applied in the field of food processing, can solve the problems of slow increase in income and production, slow sales of agricultural products, difficult sales, etc., to avoid the problem of oil deterioration, reduce the oxygen concentration, and reduce the frying temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

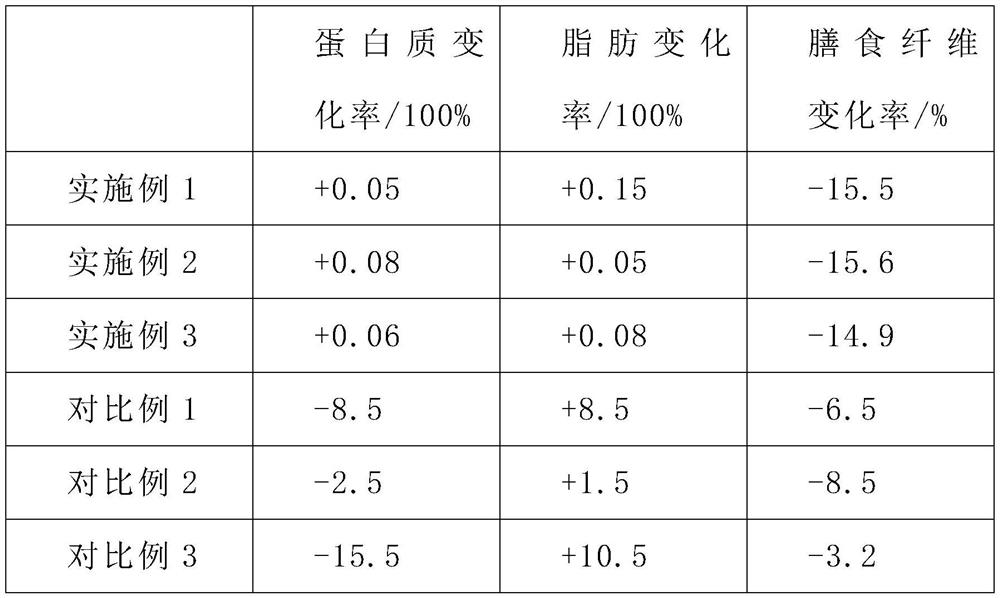

Examples

Embodiment 1

[0029] Preparation of fermented yeast liquid: cut the stem of amaranth into short stalks with a length of 1 mm, mix the short stalks with water at a mass ratio of 1:3, let stand and soak for 12 hours at room temperature, and filter to obtain the filtrate; The grain food and the filtrate are mixed at a mass ratio of 1:1, and 10% pectin is added to the grain food mass, and fermented in airtight conditions at room temperature for 24 hours, filtered, and the yeast liquid is obtained;

[0030] Pickling: After mixing the grain food and fermented yeast liquid at a mass ratio of 1:3, ultrasonic treatment at an ultrasonic frequency of 45 kHz for 3 minutes, standing at room temperature for 24 hours, and suction filtration to obtain pickled grains;

[0031] Frozen pressing: After freezing the pickled grains at a temperature of -75°C for 10 minutes, press them at a pressure of 3 MPa for 10 minutes to obtain pressed pickled grains;

[0032] Vacuum frying: Put the pressed pickled grains int...

Embodiment 2

[0035] Preparation of fermented yeast liquid: cut the stem of amaranth into short stalks with a length of 5 mm, mix the short stalks with water at a mass ratio of 1:10, let stand and soak for 36 hours at room temperature, filter to obtain the filtrate; The grain food and the filtrate are mixed at a mass ratio of 1:5, and 20% pectin by weight of the grain food is added, and fermented in airtight conditions at room temperature for 48 hours, and then filtered to obtain the fermented yeast liquid;

[0036] Pickling: After mixing the grain food and fermented yeast liquid at a mass ratio of 1:10, ultrasonic treatment at an ultrasonic frequency of 50 kHz for 10 minutes, standing at room temperature for 36 hours, and suction filtration to obtain pickled grains;

[0037] Frozen pressing: After freezing the pickled grains at a temperature of -85°C for 30 minutes, press them at a pressure of 15 MPa for 80 minutes to obtain pressed pickled grains;

[0038]Vacuum frying: Put the pressed pi...

Embodiment 3

[0041] Preparation of fermented yeast liquid: cut the stem of amaranth into short stalks with a length of 3 mm, mix the short stalks with water at a mass ratio of 1:5, leave to soak at room temperature for 15 hours, filter to obtain the filtrate; The grain food and the filtrate are mixed according to the mass ratio of 1:3, and pectin with 15% of the grain food quality is added, and the closed fermentation is carried out at room temperature for 28 hours, and the yeast liquid is obtained by filtering;

[0042] Pickling: After mixing the grain food and fermented yeast liquid at a mass ratio of 1:5, ultrasonic treatment at an ultrasonic frequency of 48 kHz for 5 minutes, standing at room temperature for 28 hours, and suction filtration to obtain pickled grains;

[0043] Frozen pressing: After freezing the pickled grains at a temperature of -80°C for 20 minutes, under the condition of a pressure of 8 MPa, heat preservation and pressing for 50 minutes to obtain pressed pickled grains...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com