A method for preparing titanium-silicon polymer oxide composite lithium-ion battery negative electrode material by thermal decomposition of organic titanium-silicon polymer

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, active material electrodes, negative electrodes, etc., can solve the problems of insignificant volume change, low initial charge and discharge efficiency, loss of specific capacity of materials, etc., to overcome the poor rate performance Good, improved cycle stability, excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

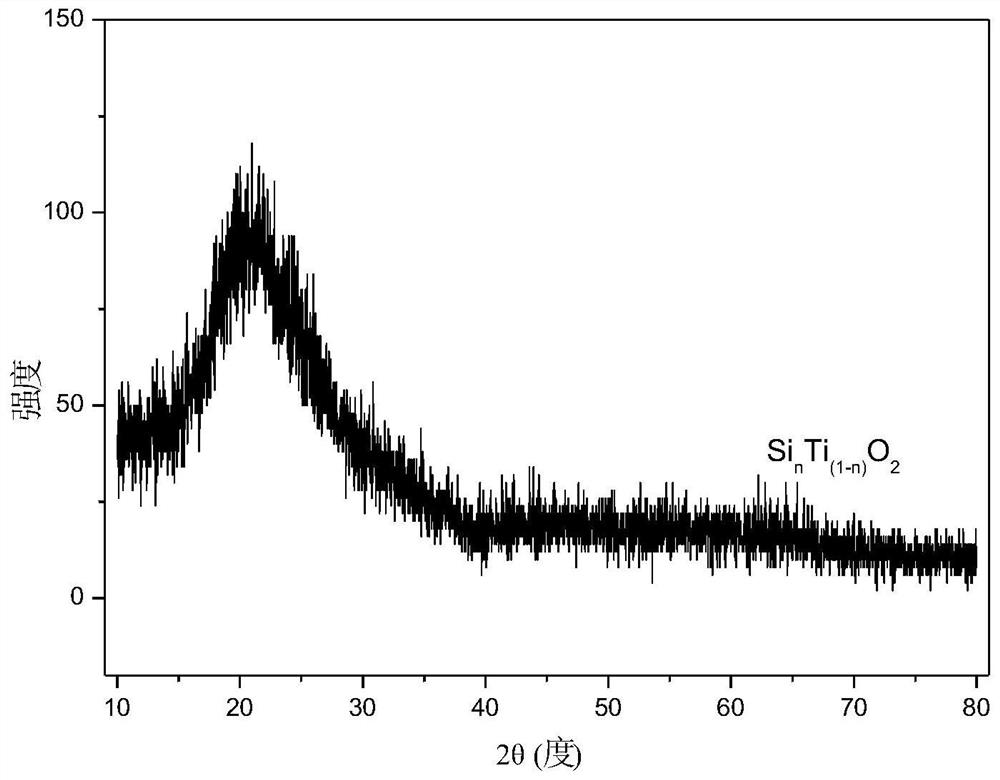

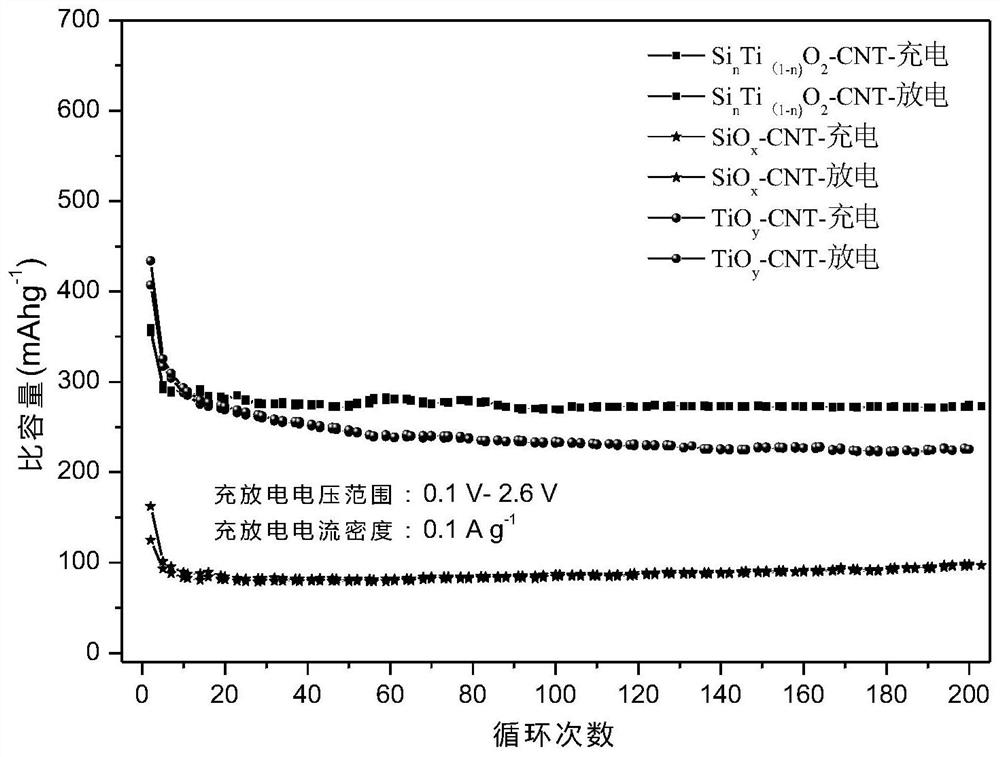

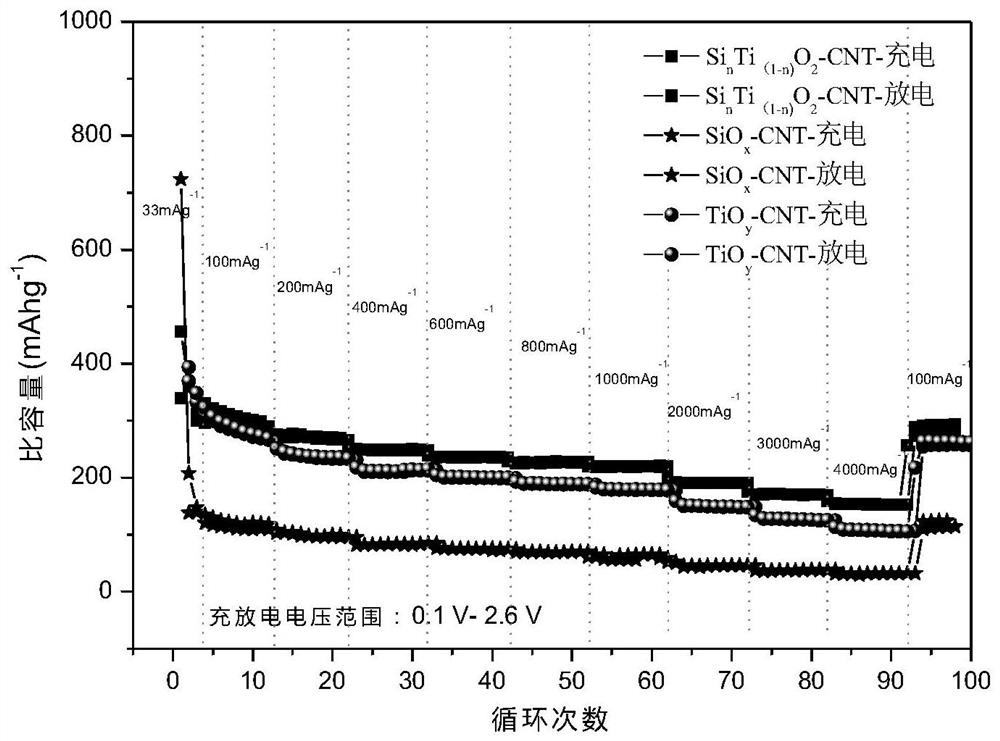

[0030] (1) Titanium silicon polymer oxide Ti n Si (1-n) O 2 - Preparation of anode material for CNT lithium ion battery

[0031] Add 0.7500g of carbon nanotube powder to the reaction kettle, then add 42.0g of anhydrous ethylene glycol (as a reactant and solvent in this example), stir evenly on a magnetic stirrer, close the lining of the reaction kettle, and send into the glove box. Then add 3.47g of tetrapropoxysilicon dropwise, add slowly while magnetically stirring, and then add 10.67g of isopropyl titanate dropwise, add 0.10g of isopropyl titanate dropwise, and then add 0.10g Finally, take out the glove box under the condition of stirring evenly, and tighten the reaction kettle. Put it into a homogeneous reactor, set the reaction temperature to 140°C, take out the reactor after 6 hours of reaction, cool it to room temperature at room temperature, remove the reaction mixture, wash the reactor three times with ethanol and combine the washed mixture with the reaction mixtu...

Embodiment 2

[0038] (1) Comparative material SiO x - Preparation of CNTs

[0039] Add 0.7500g of carbon nanotube powder to the reaction kettle, then add 42.0g of anhydrous ethylene glycol (as a reactant and solvent in this example), stir evenly on a magnetic stirrer, close the lining of the reaction kettle, and send into the glove box. Then add 3.47g of tetrapropoxysilicon dropwise, add slowly and magnetically stir, wait for the mixing to be uniform, then add 0.10g of cetyldimethylamine, and finally take out the glove box under the condition of uniform stirring , tighten the reactor. Put it into a homogeneous reactor, set the reaction temperature to 140 °C, take out the reaction kettle after 6 hours of reaction, cool it to room temperature, transfer the reaction mixture, wash the reaction kettle three times with 10 ml of ethanol respectively, combine the washings into the reaction mixture, extract The solid filter cake was obtained by filtration and separation, and the filter cake was t...

Embodiment 3

[0043] (1) Comparative material TiO y- Preparation of CNTs

[0044] Add 0.7503g of carbon nanotube powder to the reaction kettle, then add 42g of anhydrous ethylene glycol (as a reactant and solvent in this example), stir evenly on a magnetic stirrer, close the lining of the reaction kettle, and send inside the glove box. Then add 10.67g of isopropyl titanate dropwise, add slowly and magnetically stir, and then add 0.10g of cetyldimethylamine after mixing evenly, finally take out the glove box after stirring evenly, and tighten the reaction kettle . Put it into a homogeneous reactor, set the reaction temperature to 140°C, take out the reaction kettle after 6 hours of reaction, cool it to room temperature, transfer the reaction mixture, wash the reaction kettle three times with 10 ml of ethanol, combine the washings into the reaction mixture, extract The solid filter cake was obtained by filtration and separation, and the filter cake was taken and placed in a blast drying ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com