Environment-friendly easily-decomposed corrugated paper and processing technology thereof

A processing technology and technology of corrugated paper, applied in the field of corrugated paper processing, can solve the problems of poor flame retardancy of corrugated paper, reduced work efficiency, slow solidification of corrugated paper, etc., to reduce the probability of burning, increase the difficulty of burning, and improve the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

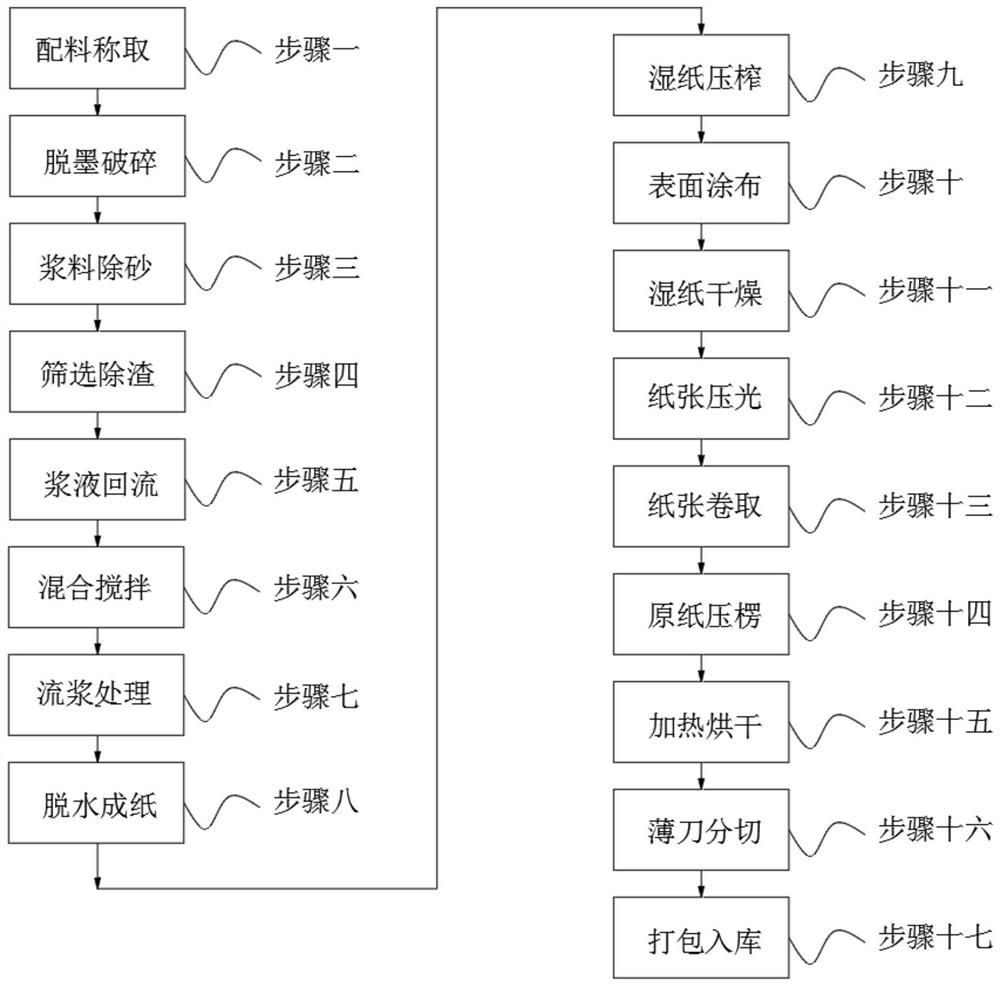

Image

Examples

Embodiment 1

[0044] An environmentally friendly and easy-to-decompose corrugated paper, the formula includes: straw pulp board, waste paper, deinking agent, retention aid, flame retardant and corn starch glue, and the parts by weight of each component are: 30-40 parts of straw Pulp board, 100-120 parts of waste paper, 0.5-0.7 parts of deinking agent, 0.12-0.2 parts of retention aid, 1-3 parts of polyurethane, 4-7 parts of flame retardant and 5-10 parts of corn Starch glue, the deinking agent is one or more mixtures of sodium carbonate, sodium hydroxide and polyoxyethylene alkylphenyl ether, and the retention aid is one of polyethyleneimine, polyacrylamide and polyethylene oxide or multiple mixtures, the flame retardant is composed of 20-30 parts of magnesium hydroxide and 3-8 parts of calcium carbonate, the corn starch glue is made of 0.1-0.25 parts of 30% hydrogen peroxide, 0.85-0.95 parts of 30 % concentration of caustic soda, 0.2-0.42 parts of borax, 12-14 parts of cornstarch, 82-86 par...

Embodiment 2

[0064] An environmentally friendly and easy-to-decompose corrugated paper, the formula includes: straw pulp board, waste paper, deinking agent, retention aid, flame retardant and corn starch glue, and the parts by weight of each component are: 30-40 parts of straw Pulp board, 100-120 parts of waste paper, 0.5-0.7 parts of deinking agent, 0.12-0.2 parts of retention aid, 1-3 parts of polyurethane, 4-7 parts of flame retardant and 5-10 parts of corn Starch glue, the deinking agent is one or more mixtures of sodium carbonate, sodium hydroxide and polyoxyethylene alkylphenyl ether, and the retention aid is one of polyethyleneimine, polyacrylamide and polyethylene oxide or multiple mixtures, the flame retardant is composed of 20-30 parts of magnesium hydroxide and 3-8 parts of calcium carbonate, the corn starch glue is made of 0.1-0.25 parts of 30% hydrogen peroxide, 0.85-0.95 parts of 30 % concentration of caustic soda, 0.2-0.42 parts of borax, 12-14 parts of cornstarch, 82-86 par...

Embodiment 3

[0084] An environmentally friendly and easy-to-decompose corrugated paper, the formula includes: straw pulp board, waste paper, deinking agent, retention aid, flame retardant and corn starch glue, and the parts by weight of each component are: 30-40 parts of straw Pulp board, 100-120 parts of waste paper, 0.5-0.7 parts of deinking agent, 0.12-0.2 parts of retention aid, 1-3 parts of polyurethane, 4-7 parts of flame retardant and 5-10 parts of corn Starch glue, the deinking agent is one or more mixtures of sodium carbonate, sodium hydroxide and polyoxyethylene alkylphenyl ether, and the retention aid is one of polyethyleneimine, polyacrylamide and polyethylene oxide or multiple mixtures, the flame retardant is composed of 20-30 parts of magnesium hydroxide and 3-8 parts of calcium carbonate, the corn starch glue is made of 0.1-0.25 parts of 30% hydrogen peroxide, 0.85-0.95 parts of 30 % concentration of caustic soda, 0.2-0.42 parts of borax, 12-14 parts of cornstarch, 82-86 par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com