Singeing device for polyester filament non-woven geotextile production

A technology of non-woven geotextiles and polyester filaments, applied in the field of textile processing, can solve the problems of affecting the process effect and unable to clean the lint, and achieve the effects of avoiding scratches, optimizing singeing effect, and easy leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

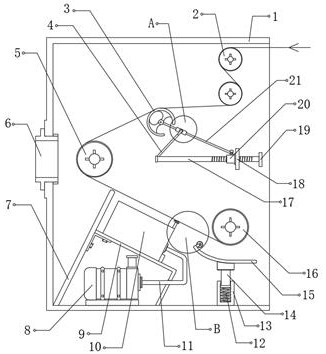

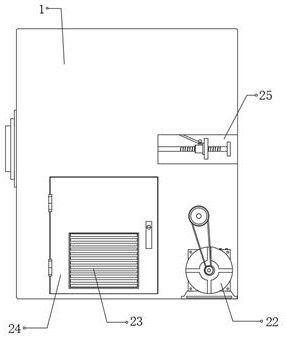

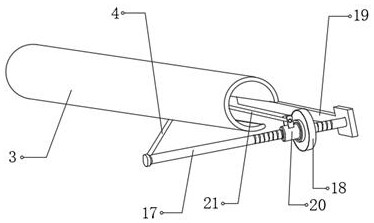

[0031] refer to Figure 1-5 , a singeing device for polyester filament non-woven geotextile production, comprising a box body 1 and a flame injection port 6, the flame injection port 6 is arranged in the middle of one side of the box body 1, and the box body 1 is away from the flame injection port 6- The top of the side inner wall is rotatably connected with two first turning rollers 2, and the middle part of the inner wall on the other side of the box body 1 is rotatably connected with a second turning roller 5 through bearings, and the inner wall of the side of the box body 1 close to the first turning roller 2 The bottom of the box is rotatably connected with a winding roller 16 through bearings, and the rotating shaft of the winding roller 16 is connected with a motor 22, the inner wall of the middle part of the box body 1 is fixedly connected with a crossbar 17, and the middle part of the crossbar 17 is threadedly connected with a knob 18, The circumference of one side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com