Repairing tool for bracket crane

A technology for maintenance tools and cranes, which is applied to mechanical equipment, engine components, engine lubrication, etc., can solve the problems of time-consuming and laborious, poor wire rope effect, etc., to prevent rust, better straightening effect, and good straightening effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Further detailed explanation through specific implementation mode below:

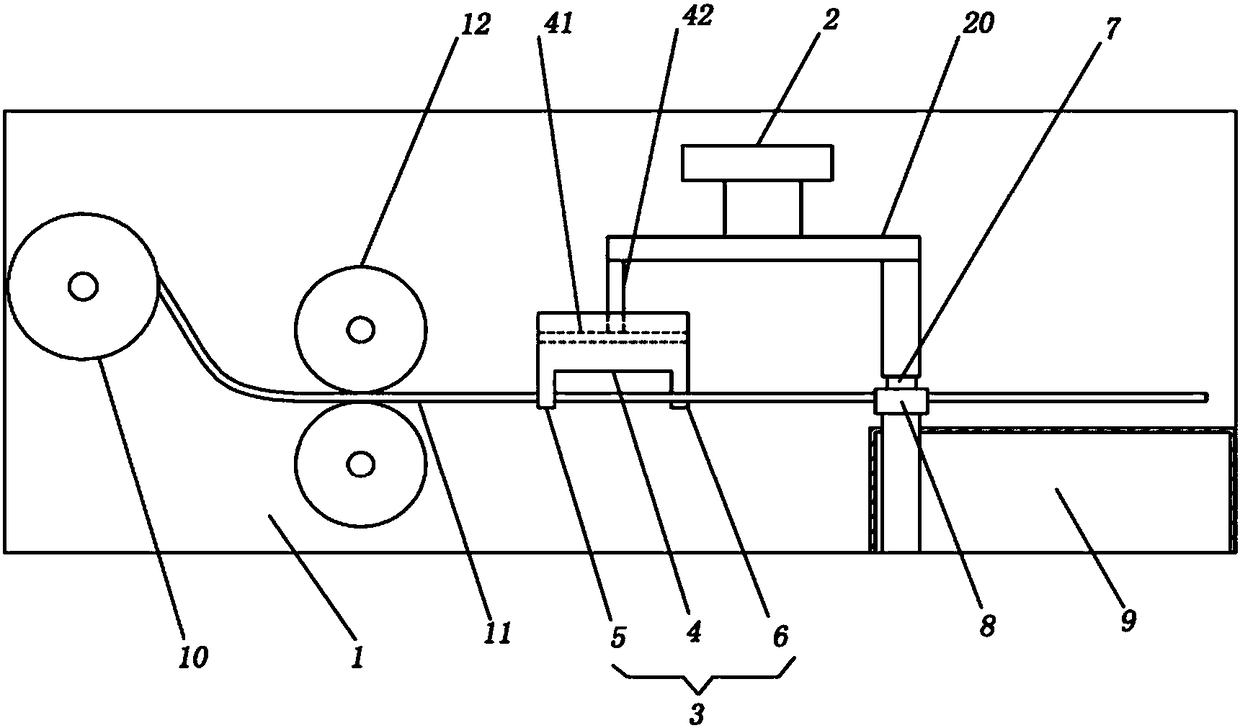

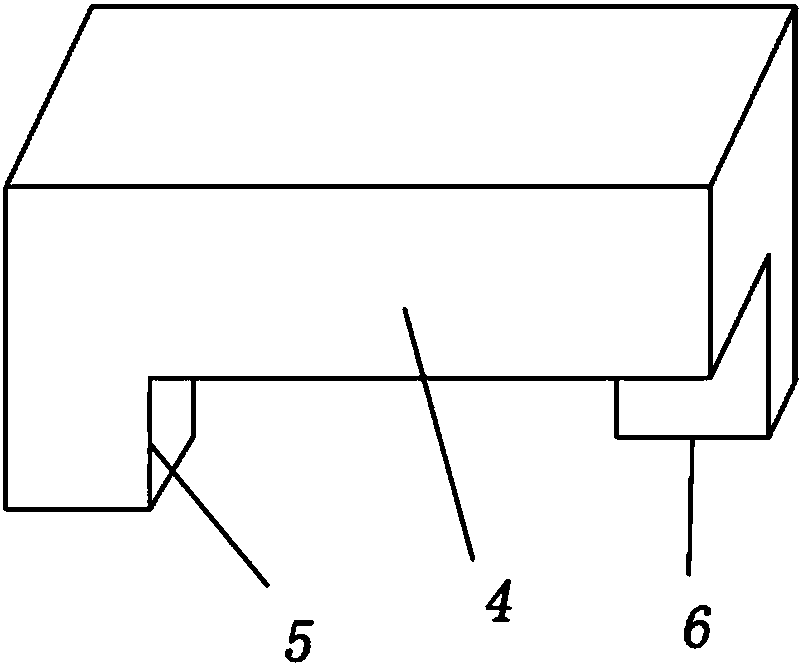

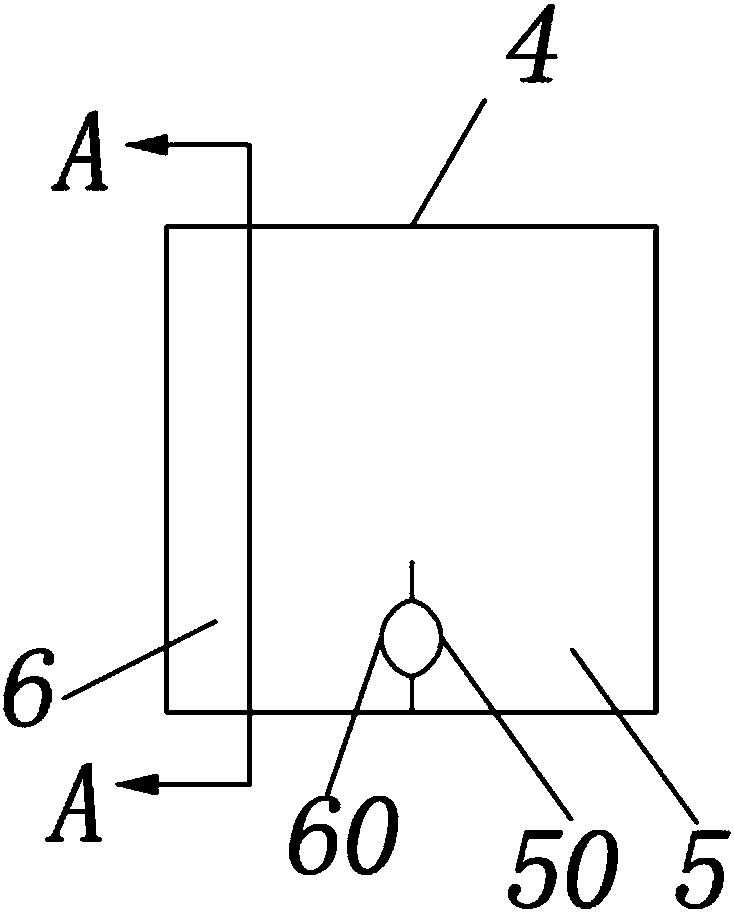

[0022] The reference signs in the drawings of the description include: frame 1, drum 10, wire rope 11, conveying roller 12, hydraulic cylinder 2, moving plate 20, straightening cylinder 3, air cylinder 4, air inlet 40, piston 41, piston Rod 42, first oil cylinder 5, first straightening groove 50, second oil cylinder 6, second straightening groove 60, oil leakage hole 61, sponge layer 62, blowing tube 63, cutting blade 7, support part 8, cutting groove 80, support plate 81, stage clip 82, material receiving chute 9.

[0023] The embodiment is basically as attached figure 1 Shown: jib crane maintenance tools, including frame 1, traction mechanism, power mechanism, straightening mechanism and cutting mechanism. The traction mechanism includes two transfer rollers 12 for conveying the wire rope 11, and the transfer roller 12 is rotatably connected with the frame 1; the left side of the transfer rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com