Method and system for preparing tetramethyldihydrodisiloxane by hydrolyzing organic silicon low-boiling-point substance and comprehensive utilization method

A technology of tetramethyldihydrodisiloxane and dimethylmonochlorosilane, which is applied in the fields of silicon organic compounds, preparation with chloride, organic chemistry, etc., can solve the problems of unstable downstream manufacturers, cumbersome residue treatment, and energy consumption Consumption and other issues, to achieve the effect of easy promotion, low cost, and reduced processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

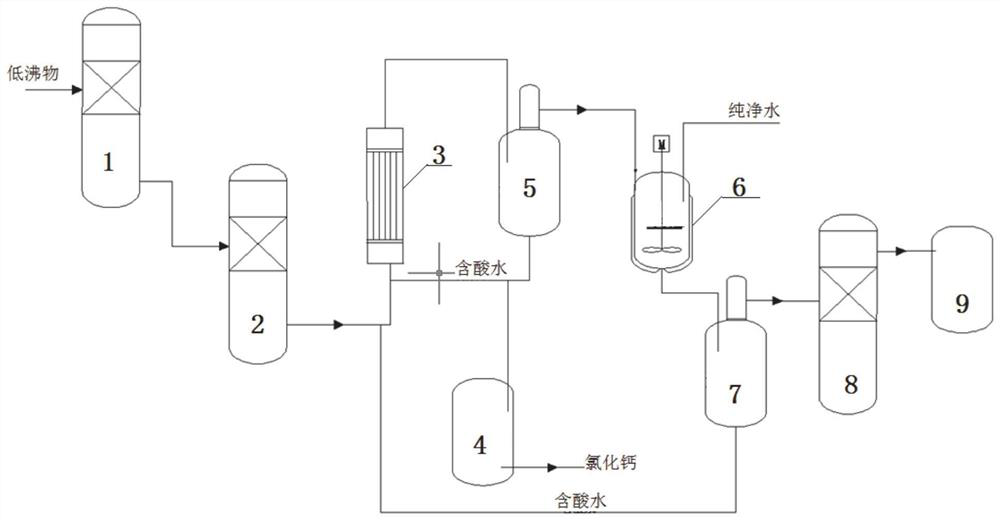

[0047] Such as figure 1 The process flow shown, a method for preparing tetramethyldihydrodisiloxane by hydrolysis of low-boiling organic silicon, includes the following steps:

[0048] (1) The rectified low-boiling matter is first sent to Sijia Tower 1 through the low-boiling feed pump, and Sijia Tower 1 starts to rise when the liquid level of Sijia Tower 1 reaches 50% to 70% of the bottom of the tower, and a total reflux operation is established. By adjusting the control parameters of Sijia Tower 1: Operating pressure: 0.25Mpa, return flow 4m 3 / hr, the top temperature of the tower is about 42℃, and the temperature of the tower bottom is about 68℃. Take reflux and tower bottom sample analysis, the content of tetramethylsilane in the reflux sample is controlled at about 90%, dimethylmonochlorosilane is less than 0.1%, and the content of tetramethylsilane in the tower bottom is less than 0.5%. For feeding, tetramethylsilane is taken from the top of the tower into the tetramethyls...

Embodiment 2

[0057] (1) The rectified low-boiling matter is first sent to Sijia Tower 1 through the low-boiling feed pump, and Sijia Tower 1 starts to rise when the liquid level of Sijia Tower 1 reaches 50% to 70% of the bottom of the tower, and a total reflux operation is established. By adjusting the control parameters of Sijia Tower 1: Operating pressure: 0.25Mpa, return flow 4m 3 / hr, the top temperature of the tower is about 42℃, and the temperature of the tower bottom is about 68℃. Take reflux and tower bottom sample analysis, the content of tetramethylsilane in the reflux sample is controlled at about 90%, dimethylmonochlorosilane is less than 0.1%, and the content of tetramethylsilane in the tower bottom is less than 0.5%. For feeding, tetramethylsilane is taken from the top of the tower into the tetramethylsilane metering tank, and the bottom of the tower is sent to the dimethylmonochlorosilane tower 2 through the dimethylmonochlorosilane feed pump, the dimethylmonochlorosilane towe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com