A volumetric fracturing waste liquid electrocoagulation destabilization separation treatment device and method

A volume fracturing and separation treatment technology, which is applied in mining wastewater treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of affecting the efficiency of electrocoagulation destabilization reaction, reducing treatment efficiency, and shortening the life of plates. Achieve the effect of realizing high-efficiency and low-cost destabilization separation treatment, reducing passivation and scaling, and accelerating the dissolution process

Active Publication Date: 2022-06-03

BC P INC CHINA NAT PETROLEUM CORP +1

View PDF12 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] However, during the application process, it was found that due to the water quality characteristics of the volumetric fracturing waste fluid, plate passivation and fouling occurred frequently during the application of the electrocoagulation process, which seriously affected the destabilization reaction efficiency of the electrocoagulation process, resulting in increased power consumption , shortened plate life, and reduced treatment efficiency, it is urgent to optimize the design of the electrocoagulation process to meet the needs of volumetric fracturing waste fluid treatment, so as to ensure the efficient application of this technology in the field of environmental protection for shale gas development

[0007] Based on the water quality characteristics of the volumetric fracturing waste fluid, how to reduce the problem of reduced reaction efficiency caused by scaling ions and keep the electrocoagulation process efficient and Cost characteristics are the primary issue for process technology improvement

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Login to View More

Abstract

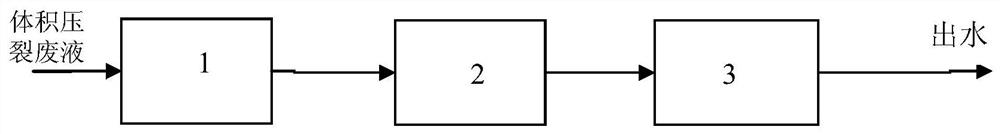

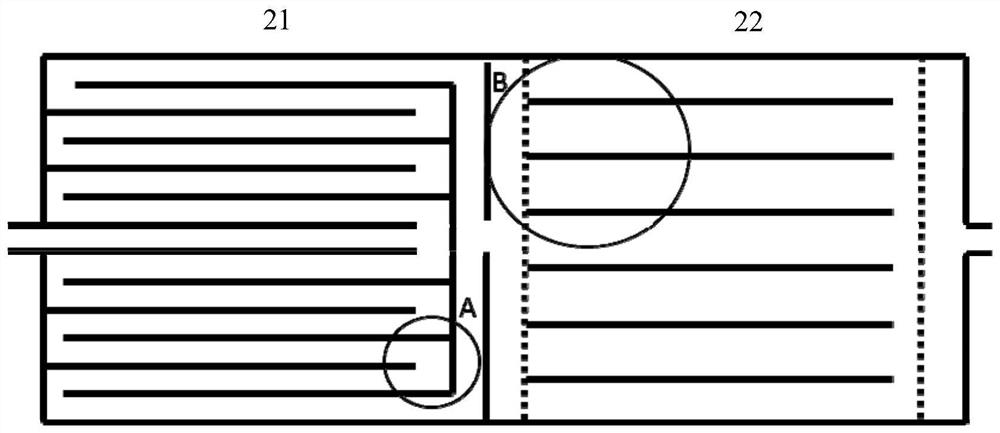

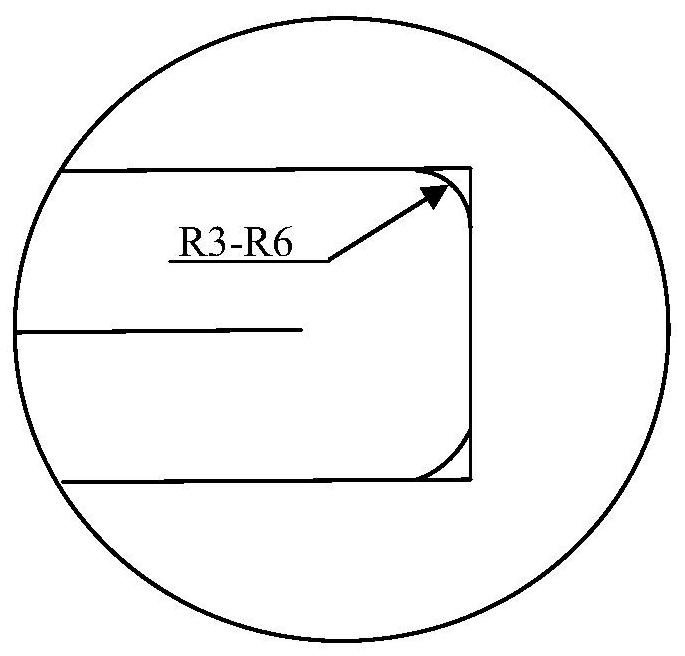

The invention provides a volumetric fracturing waste liquid electrocoagulation destabilization separation treatment device and method, the device comprises: a homogeneous adjustment tank, an electro-flocculation reaction tank and a sedimentation separation tank; a homogeneous adjustment tank, an electro-flocculation reaction tank and a sedimentation tank The separation pools are connected sequentially; inside the homogeneous adjustment pool, there are several independent waste liquid storage tanks that are not connected to each other, and an online chlorine ion monitoring instrument is installed at the entrance of the homogeneous adjustment pool; A number of electric valves and mixers that can automatically adjust the opening range; the electroflocculation reaction pool is equipped with a front-end destabilization reaction zone and a rear-end flocculation reaction zone, and the front-end destabilization reaction zone and the rear-end flocculation reaction zone are respectively equipped with The electrode plate group, and the flow channel between the plates in the front destabilization reaction zone is an S-shaped series structure, and the flow channel between the plates in the back-end flocculation reaction zone is a parallel structure. The invention can realize high-efficiency and low-cost destabilization and separation treatment of volumetric fracturing waste liquid.

Description

A kind of volume fracturing waste liquid electroflocculation destabilization separation treatment device and method technical field The present invention relates to a kind of volume fracturing waste liquid electro-flocculation destabilization separation treatment device and method, belong to the industrial waste water place The field of science and technology. Background technique The development of shale gas resources has been gradually accelerated in recent years, as the volume fracturing method that must be used in the shale gas development process. Due to its characteristics of large water consumption, large flowback liquid, and long flowback period, it has always been an important environment in the process of shale gas development. influencing factors. During the process of flowback from the formation to the surface, the volume fracturing waste liquid entrains some suspended solids and salts in the formation water. The composition of fracturing waste fluid is ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C02F1/463C02F103/10

CPCC02F1/463C02F1/46104C02F2001/46119C02F2103/10

Inventor 张晓飞罗臻张华王毅霖吴百春刘译阳李婷

Owner BC P INC CHINA NAT PETROLEUM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com