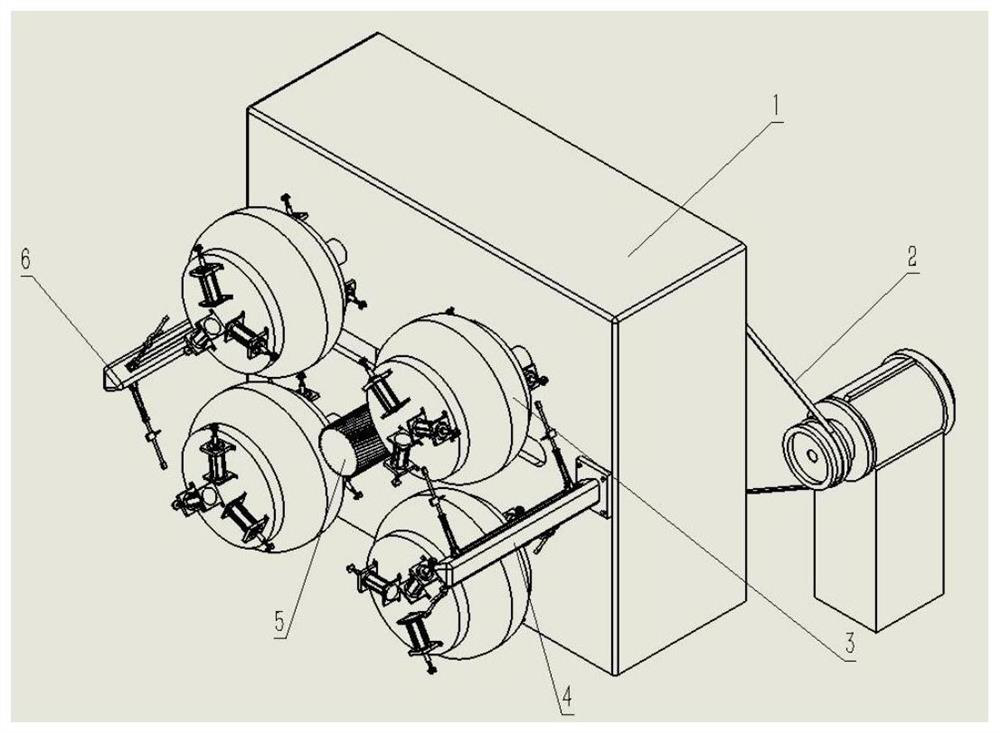

Tire deburring device and method

A technology for deburring and tires, applied in tires, household appliances, metal processing, etc., can solve problems such as low production efficiency, unguaranteed safety, and tread damage, so as to improve work efficiency, increase the scope of application, The effect of improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

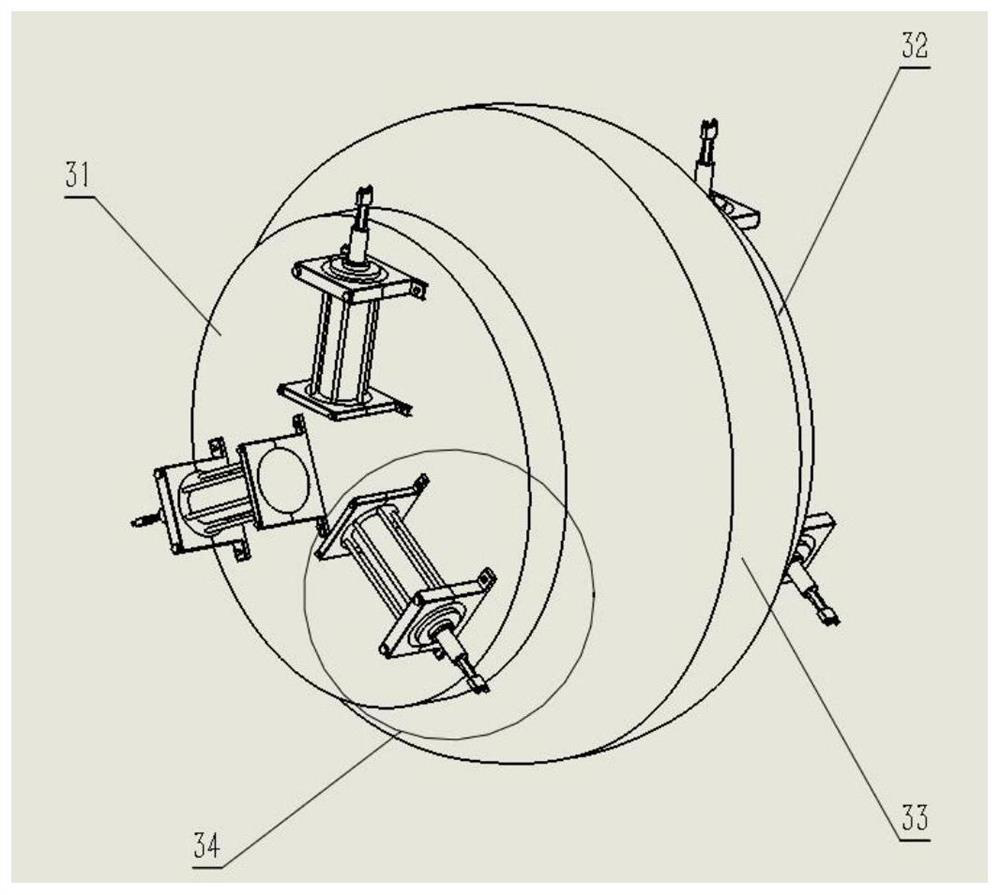

[0044] 1. When the two 135 / 80R12 tires to be processed are sent to the upper and lower stations on the right, the right tire clamping device is activated, and the two tires are respectively set on the upper and lower airbags on the right, and are inflated by the air pump. The air at 240KPa supports the inner surface of the tire, and the plunger in the telescopic cylinder has a stroke of 5mm, so that the distance between the front end cover and the rear end cover changes, so as to adapt to the tire section width of 135 / 80R12 tire to be processed, which is 135mm. The cylinder in the mouth support mechanism pushes the electric gripper to clamp the tire mouth, and the electric gripper adapts to the width of the mouth of the tire to be processed to 20mm, so as to complete the fixing of the tire to be processed.

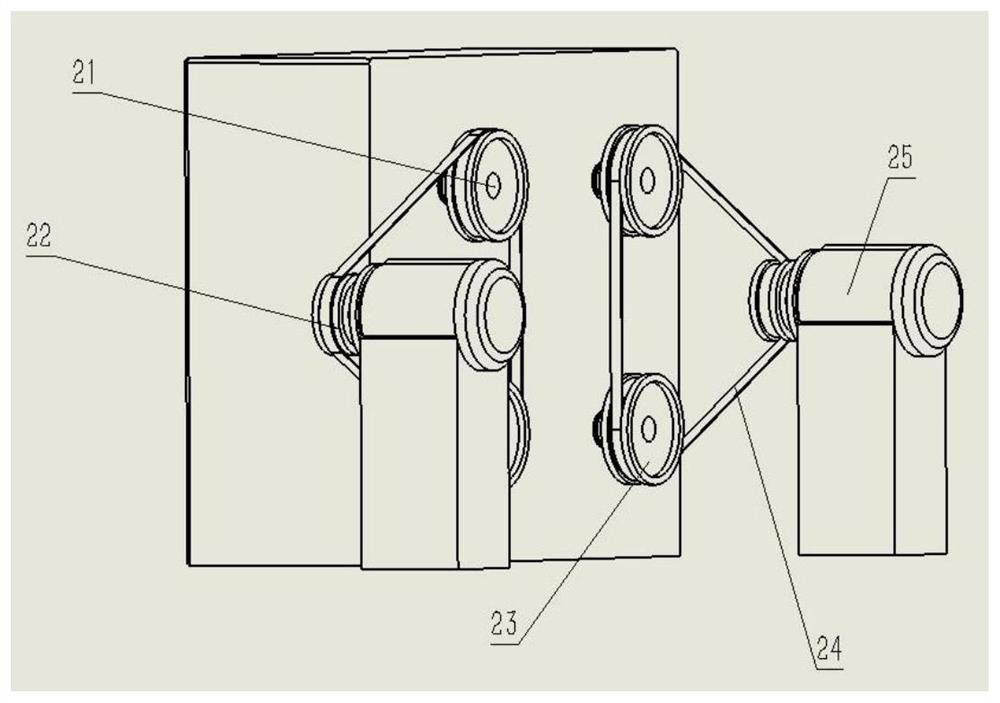

[0045] 2. The right tire clamping and rotating device is started, and the first driving motor provides a speed of 1440r / min. After the deceleration mechanism, the rotating ...

Embodiment 2

[0051] 1. When the two 225 / 45R16 tires to be processed are sent to the upper and lower stations on the right, the right tire clamping device is activated, and the two tires are respectively set on the upper and lower airbags on the right, and are filled by the air pump. The air at 250KPa supports the inner surface of the tire, and the plunger in the telescopic cylinder has a stroke of 95mm, so that the distance between the front end cover and the rear end cover changes, so as to adapt to the tire section width of 225 / 45R16 tire to be processed, which is 225mm. The cylinder in the mouth support mechanism pushes the electric grippers to clamp the rim of the tire, and the electric gripper adapts to the width of the rim of the tire to be processed at 25 mm, so as to complete the fixing of the tire to be processed.

[0052] 2. The right tire clamping and rotating device is started, and the first driving motor provides a speed of 1440r / min. After the deceleration mechanism, the rotatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com