a solid co 2 Exhaust gas treatment system of washing machine

A tail gas treatment, CO2 technology, applied in the direction of solidification, inorganic chemistry, climate sustainability, etc., can solve the problems of accelerating global warming, aggravating environmental pollution, polluting the environment, etc., to improve the efficiency of dry ice manufacturing, reduce emissions, reduce The effect of power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

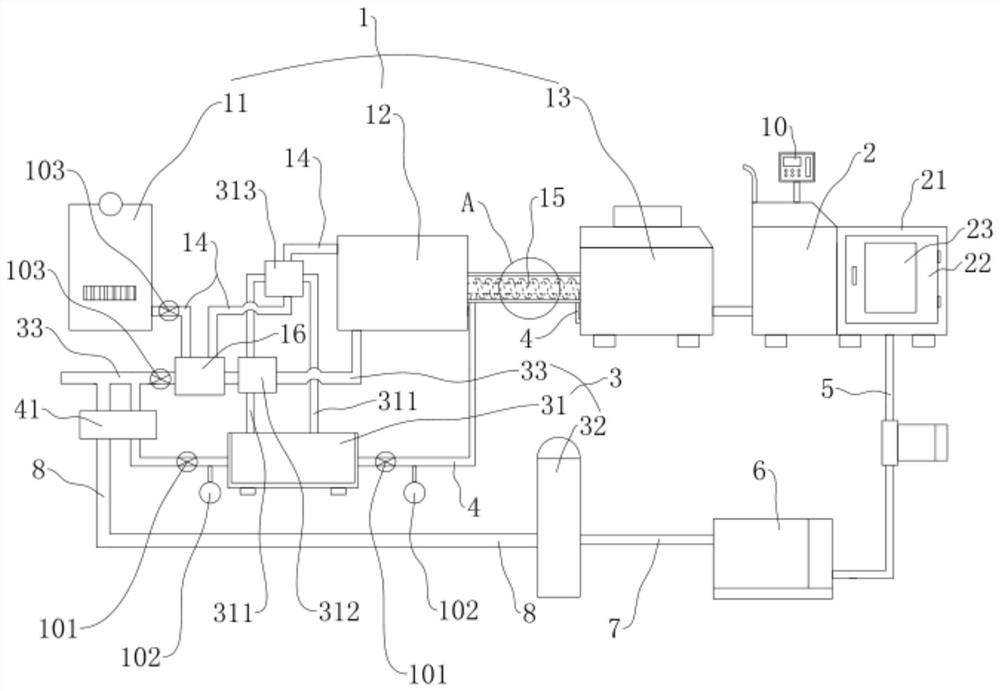

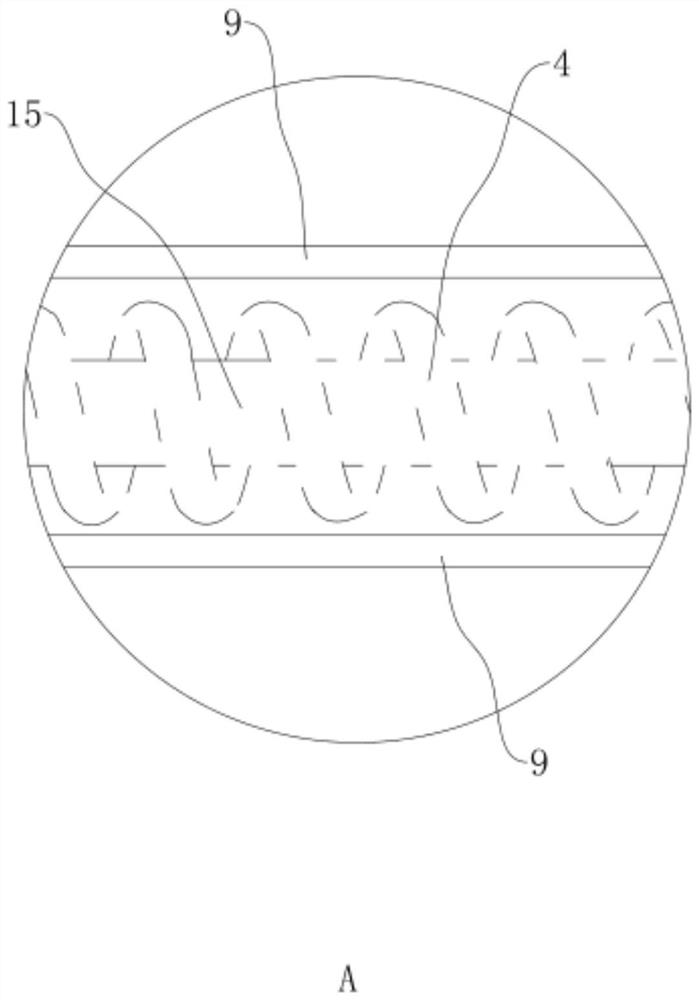

[0025] refer to Figure 1 to Figure 3 Further explain the tail gas treatment system of the solid CO2 cleaning machine.

[0026] A kind of exhaust gas treatment system of solid-state CO2 cleaning machine, such as figure 1 As shown, it includes a dry ice manufacturing device 1, a dry ice blasting device 2 connected with the dry ice manufacturing device 1, and an exhaust device 3 for recovering exhaust gas. The exhaust gas device 3 is connected with the dry ice manufacturing device 1 and the dry ice cleaning device 2, and can be used for recycling The exhaust gas of the operator is cleaned and reused to reduce the emission of carbon dioxide and improve the effect of energy saving and environmental protection.

[0027] Such as figure 1 with figure 2 As shown, the dry ice manufacturing device 1 includes a gaseous carbon dioxide supplier 11, a liquid carbon dioxide generator 12, and a dry ice compressor 13. The gaseous carbon dioxide attack device is connected to the liquid carb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com