Process for producing nickel-cobalt salt and ammonium salt through continuous crystallization

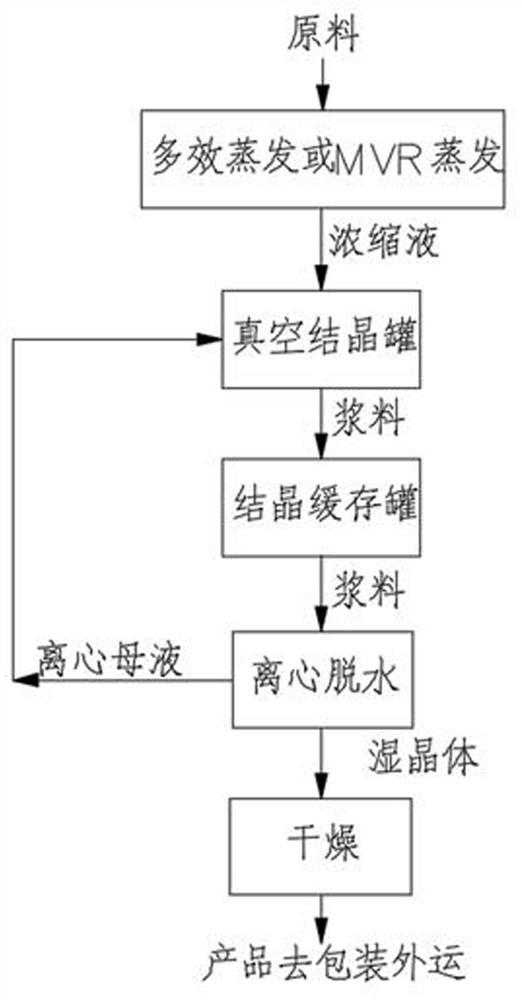

A technology of crystallization and nickel-cobalt, which is applied in the field of continuous crystallization production process of salt, can solve the problems of intermittent operation of the system, low degree of automation, and large footprint, and achieve continuous and stable operation, high degree of automation, and small footprint Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Continuous crystallization process for the production of cobalt sulfate. The cobalt sulfate saline solution is 25°C, and the saline solution with a cobalt sulfate concentration of 23% is concentrated through a multi-effect evaporator or MVR evaporation device. The concentrated cobalt sulfate concentration is 41%, and the temperature is 72°C; the concentrated solution enters the vacuum crystallization Flash cooling after the tank, control the temperature of the solution in the vacuum crystallization tank to 48°C, the temperature of the secondary steam generated by the flash is 42°C, and the concentration of cobalt sulfate is 33%. The feed liquid precipitates salt crystals in the vacuum crystallization tank to obtain a slurry. The secondary steam generated by the vacuum crystallization tank is cooled by exchanging heat with the circulating cooling water through the surface cooler to obtain condensed water and a small amount of non-condensable steam. The non-condensable ste...

Embodiment 2

[0019] A continuous crystallization process for the production of nickel sulfate. Nickel sulfate salt-containing solution at 40°C, the salt-containing solution with a nickel sulfate concentration of 21% is concentrated through a multi-effect evaporator or MVR evaporation device, the concentrated nickel sulfate concentration is 41%, and the temperature is 95°C; the concentrated solution enters the vacuum crystallization Flash cooling after the tank, control the temperature of the solution in the vacuum crystallization tank to 45°C, the temperature of the secondary steam generated by the flash is 40°C, and the concentration of nickel sulfate is 33%. The feed liquid precipitates salt crystals in the vacuum crystallization tank to obtain a slurry. The secondary steam generated by the vacuum crystallization tank is cooled by exchanging heat with the circulating cooling water through the surface cooler to obtain condensed water and a small amount of non-condensable steam. The non-con...

Embodiment 3

[0021] Continuous crystallization process for the production of ammonium chloride. A saline solution with an ammonium chloride concentration of 5.9% at a temperature of 30°C is concentrated through a multi-effect evaporator or MVR evaporator. The concentrated ammonium chloride concentration is 40% and the temperature is 75°C; the concentrated solution enters a vacuum crystallization tank After flashing, the temperature of the solution in the vacuum crystallization tank is controlled to be 54°C, the temperature of the secondary steam generated by the flashing is 42°C, and the concentration of ammonium chloride is 34%. The feed liquid precipitates salt crystals in the vacuum crystallization tank to obtain a slurry. The secondary steam generated by the vacuum crystallization tank is cooled by exchanging heat with the circulating cooling water through the surface cooler to obtain condensed water and a small amount of non-condensable steam. The non-condensable steam is pumped out by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com