Concentrated milk with improved taste

A concentrated milk and taste technology, applied in the field of concentrated milk, can solve the problems of increasing product sweetness and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

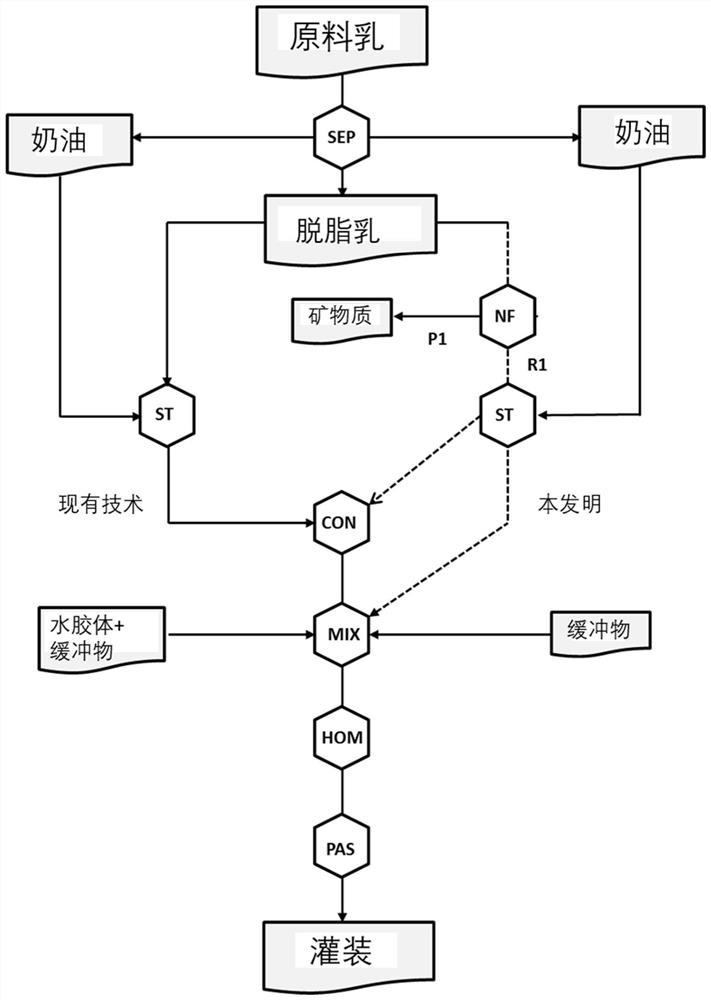

Method used

Image

Examples

Embodiment 1

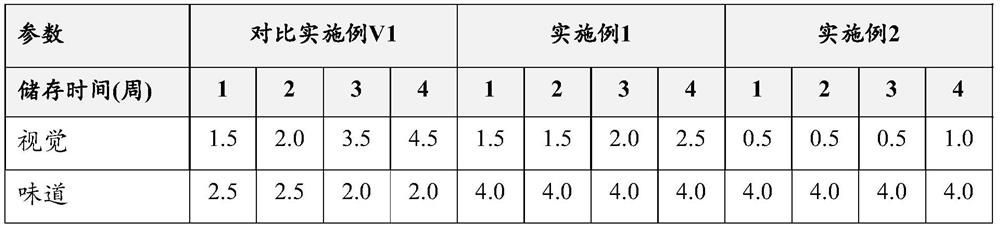

[0075] Comparative Example V1 was repeated, but without carrageenan and with 2.0 kg of a 35% by weight buffer solution consisting of 1:1 molar sodium dihydrogen phosphate and sodium citrate instead of 1.5 kg of 35% by weight phosphate buffered saline solution.

Embodiment 2

[0077] 5,000 liters of raw milk flow continuously through a combination of plate heat exchanger and separator at 55°C, followed by dedusting and skimming. The resulting skim milk was subjected to nanofiltration at 20°C using a ceramic membrane with an average pore size of 1000 Daltons. The mineral-rich permeate was discharged and the partially demineralized and protein-rich retentate was adjusted to a fat content of 2% by weight in dry matter by addition of part of the pre-separated milk fat. The milk thus standardized was dehydrated in a falling-film evaporator until a fat-free dry matter of 18% by weight and a fat of 4% by weight was achieved. 2.0 kg of a 35% by weight buffer solution consisting of 1:1 molar sodium dihydrogen phosphate and sodium citrate was then added to the concentrate to establish a pH of approximately 6.4. The mixture was then homogenized in a stirred tank for 30 minutes, followed by brief heating (3 minutes, 121° C.), and the product pasteurized in thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com