Double-material-barrel type capillary rheometer

A capillary rheometer and capillary technology, applied in the field of rheology testing, can solve problems such as single structure design, unfavorable use, equipment damage, etc., and achieve the effect of obvious dissolution effect, wide coverage area and strong heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

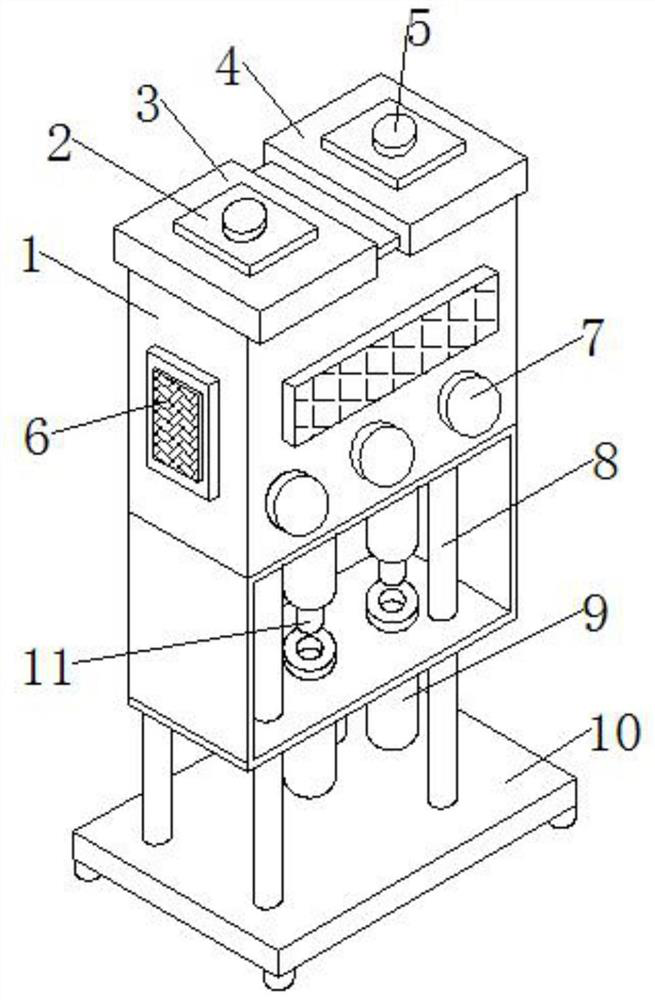

[0025] refer to Figure 1-4 ,

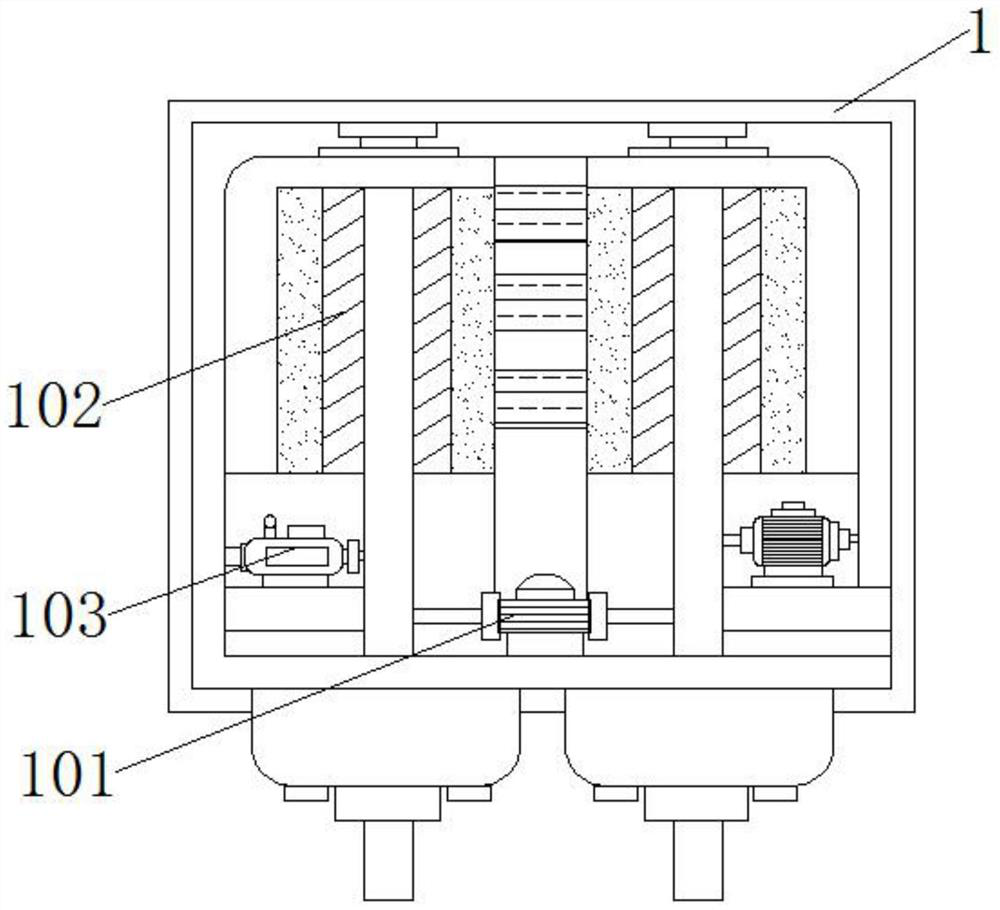

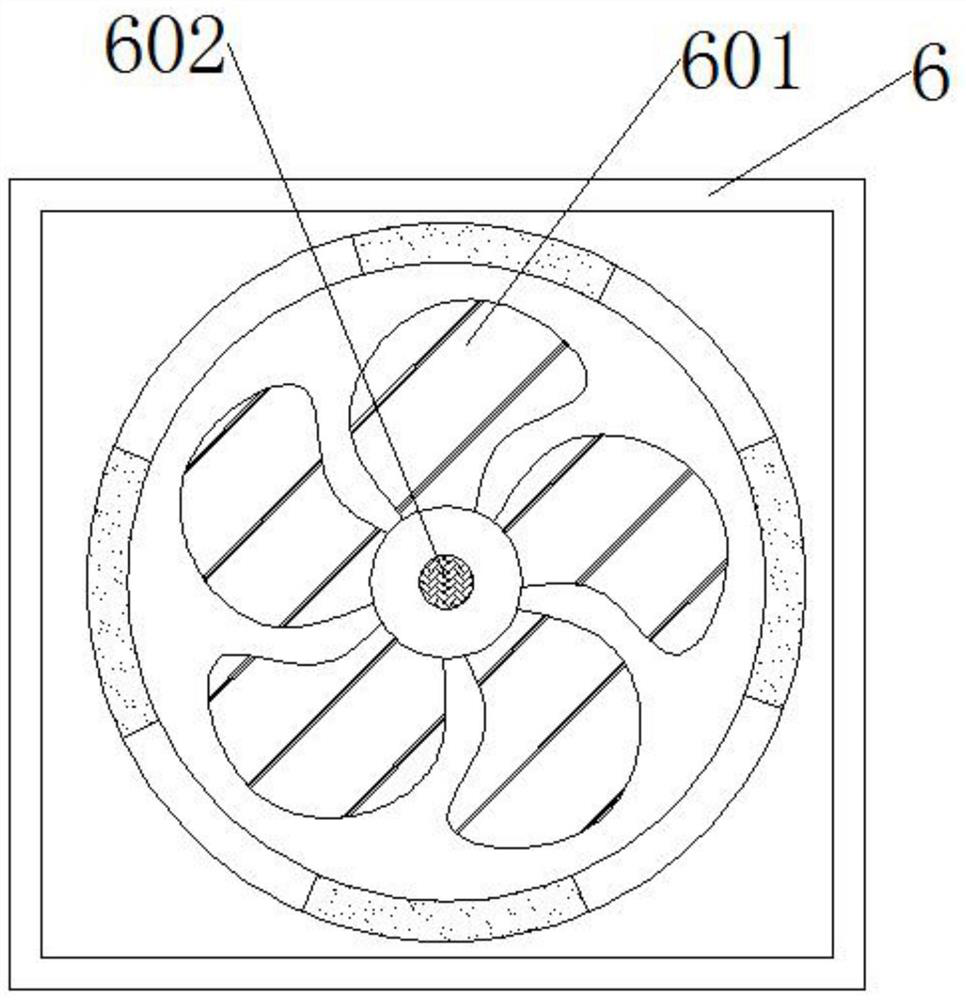

[0026] A double-barrel capillary rheometer provided in this embodiment includes a case 1, a cover 2 and a barrel 3, the cover 2 is located at the top of the case 1, and the cover 2 is movably connected with the case 1, and the left end of the inside of the case 1 A material barrel 3 is provided, and the a material barrel 3 is fixedly connected with the chassis 1, and the b material barrel 4 is provided at the inner right end of the chassis 1, and the b material barrel 4 is fixedly connected with the chassis 1, and the inside of the chassis 1 is provided with a pressure relief valve 101, And the pressure relief valve 101 is fixedly connected with the cabinet 1, the inside of the cabinet 1 is provided with a heating plate 102, and the heating plate 102 is fixedly connected with the cabinet 1, the inside of the cabinet 1 is provided with a heater 103, and the heater 103 is fixedly connected with the cabinet 1, the machine The upper end of the cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com