Efficient multi-stage braking mechanism

A braking mechanism, efficient technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

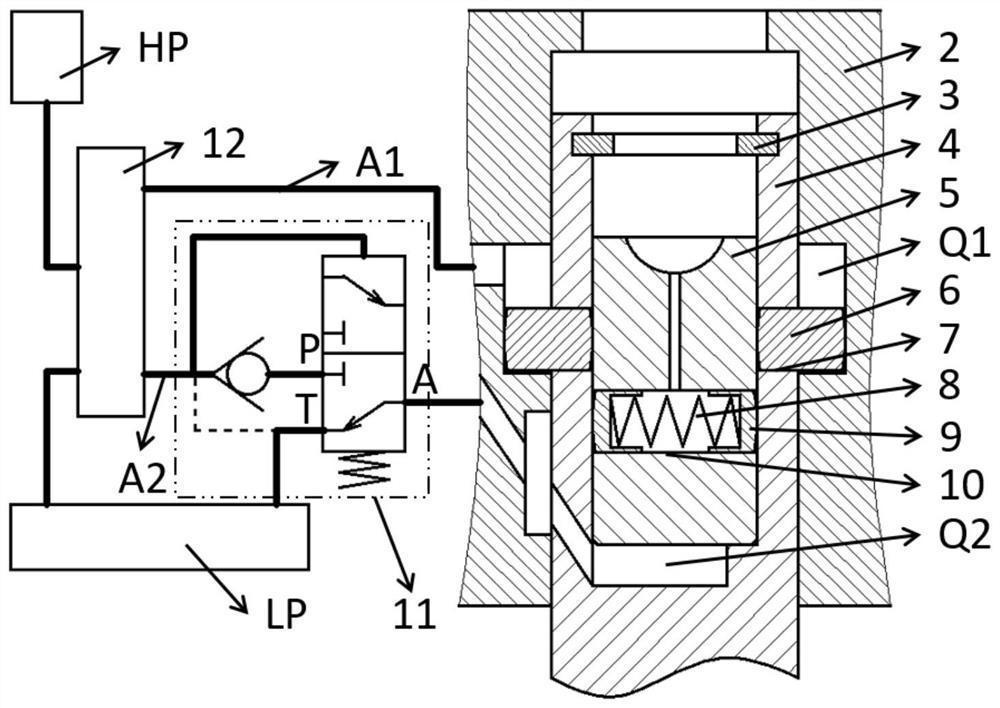

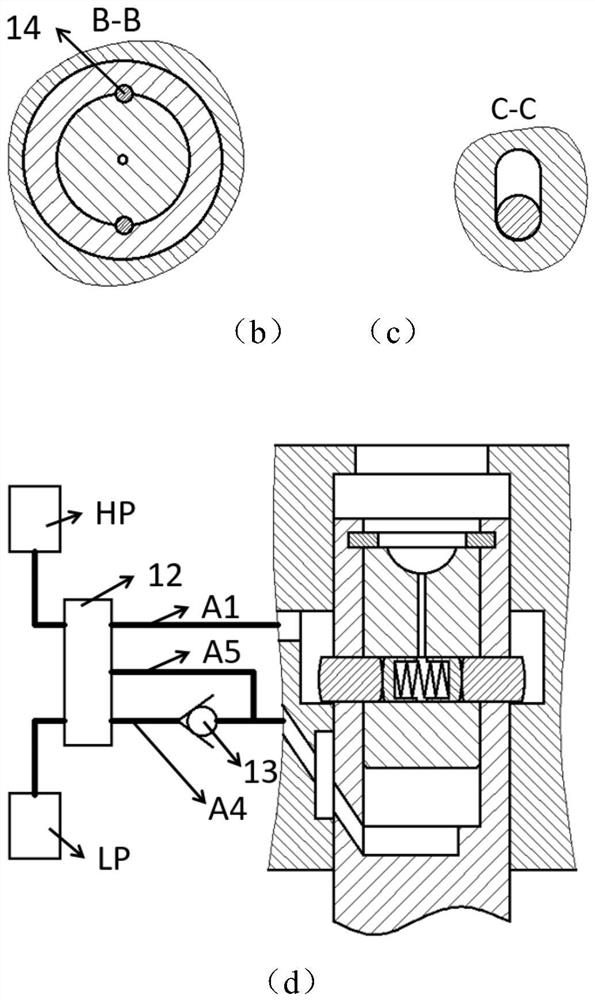

[0052] figure 1 It is a structural schematic diagram of Embodiment 1 of this mechanism. Such as figure 1 It can be seen that the mechanism includes a housing 2 , a plunger sleeve 4 arranged on the housing 2 and reciprocating relative to the housing 2 , a plunger 5 arranged on the plunger sleeve 4 and reciprocating relative to the plunger sleeve 4 , and a hydraulic control unit 12 . A second oil chamber Q2 is formed between the plunger 5 and the plunger sleeve 4 . A collar is provided on the plunger sleeve 4 as a limit setting for limiting the maximum volume of the second oil chamber Q2. Two first passages 7 are arranged on the side wall of the plunger sleeve 4 , and each first passage 7 is provided with a locking body 6 that reciprocates relative to the first passage 7 . A first oil chamber Q1 is formed between the plunger sleeve 4 , the housing 2 and the locking body 6 . The hydraulic control unit 12 is connected to the first oil chamber Q1 through the first oil passage...

Embodiment 2

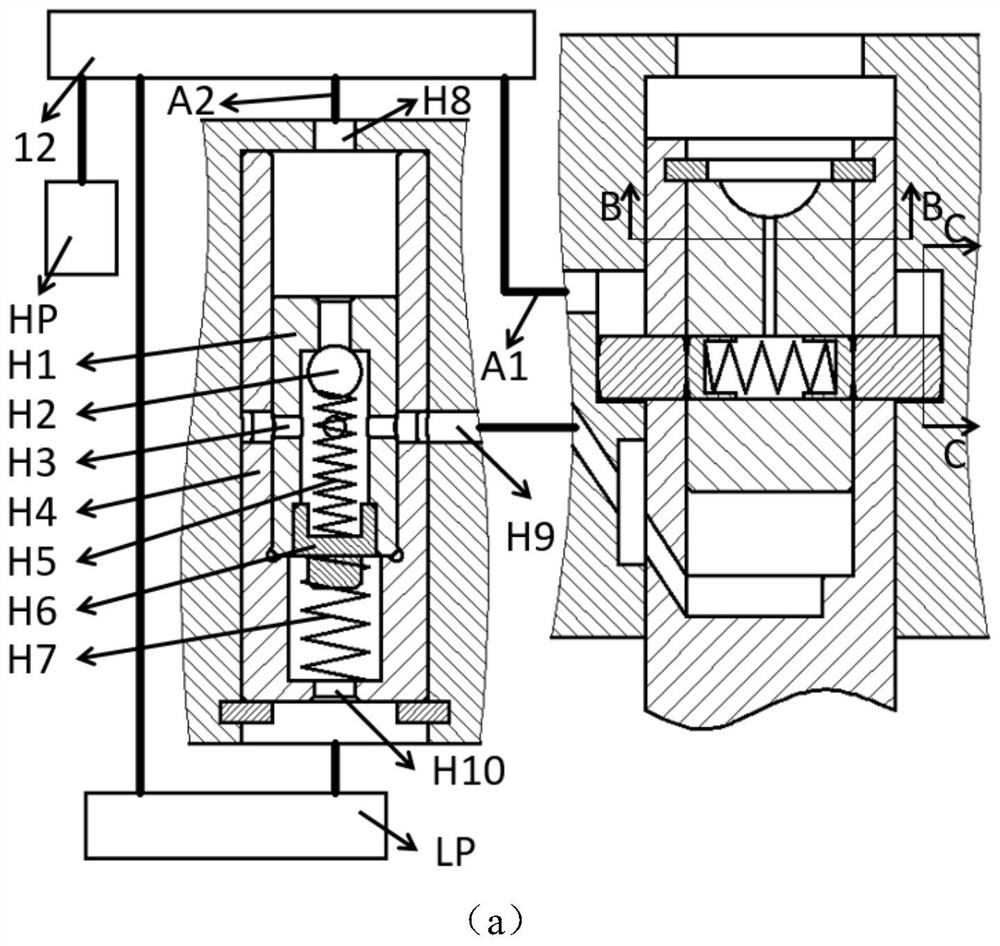

[0059] image 3 It is a structural schematic diagram of Embodiment 2 of this mechanism. Such as image 3 It can be seen that the mechanism includes a housing 2 , a plunger sleeve 4 fixed on the housing 2 , a plunger 5 arranged on the plunger sleeve 4 and reciprocating relative to the plunger sleeve 4 , and a hydraulic control unit 12 . A second oil chamber Q2 is formed between the plunger 5 and the plunger sleeve 4 . A shoulder is set on the plunger sleeve 4 to limit the limit setting of the maximum volume of the second oil chamber Q2. Three first passages 7 uniformly distributed in the circumferential direction are arranged on the side wall of the plunger sleeve 4 , and each first passage 7 is respectively provided with a locking body 6 that reciprocates relative to the first passage 7 .

[0060] image 3 The third reset scheme is adopted, the side wall of the plunger 5 is provided with a circumferential groove, the third oil chamber Q3 is arranged between the plunger 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com