Oil stain adsorption device for non-planar metal workpiece

A technology of metal workpieces and adsorption devices, which is applied in the field of powder steel processing devices, can solve the problems of waste of manpower, large limitations, and difficulty in removal, and achieve the effect of convenient power connection and power disconnection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

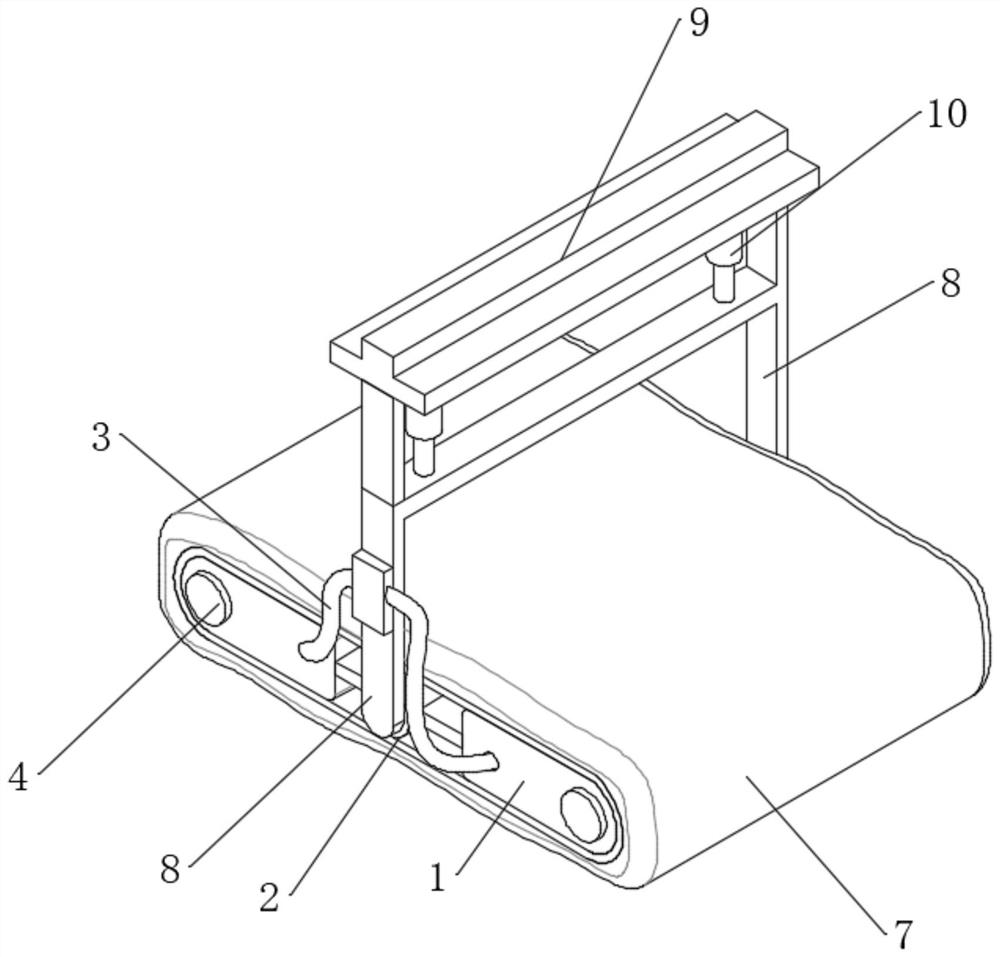

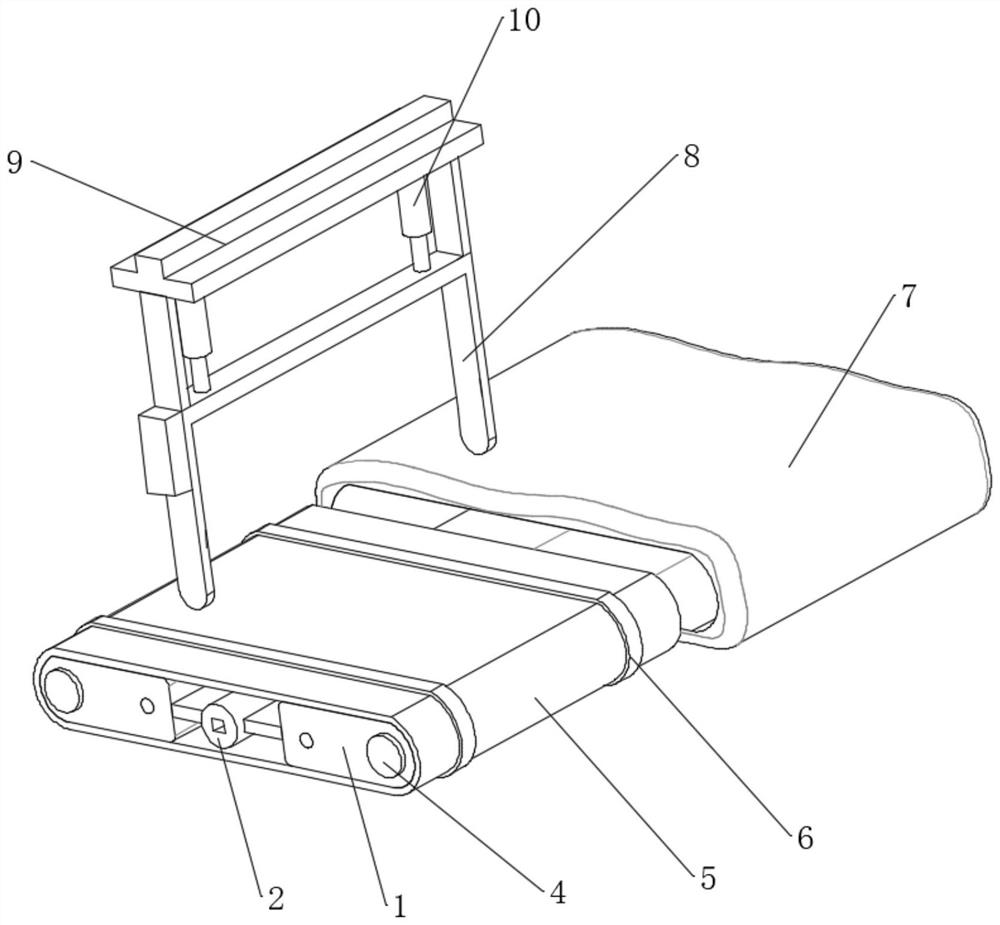

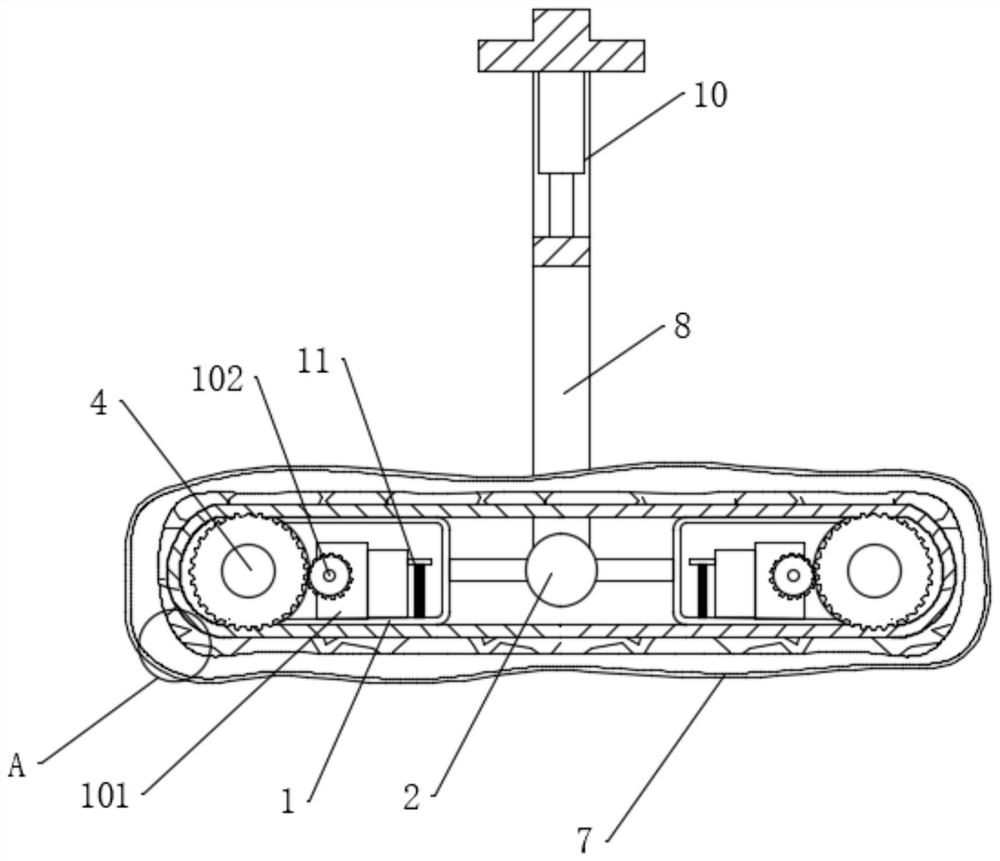

[0038] see Figure 1-3 and Figure 6, an oil dirt adsorption device for non-planar metal workpieces, comprising a pair of housings 1, a central shaft 2 is arranged between the pair of housings 1, the central shaft 2 includes a connecting shaft 201, and both sides of the connecting shaft 201 are provided There is a motor 202, a hinged plate 203 is fixedly connected to the power output end of the connecting shaft 201, the hinged plate 203 is fixedly connected to the housing 1, and a support 8 is connected between the two connecting shafts 201; a power supply is connected to the support 8, and the power supply and A conductive wire 3 is connected between the shells 1, and a fixed plate 9 is fixedly connected to the upper end of the bracket 8. A person skilled in the art designs an electric guide rail that matches the workpiece, and then the fixed plate 9 is slidably connected to the electric guide rail, so that the device It can move along the designated route. The route design ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com