Preparation device and preparation method for titanium alloy composite material

A composite material and preparation device technology, which is applied in the direction of additive processing, etc., can solve the problems of large arc heat input, affecting the forming accuracy of composite materials, microstructure grains, heat accumulation effect, etc., and achieves small heat input and grain refinement. , The effect of high deposition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

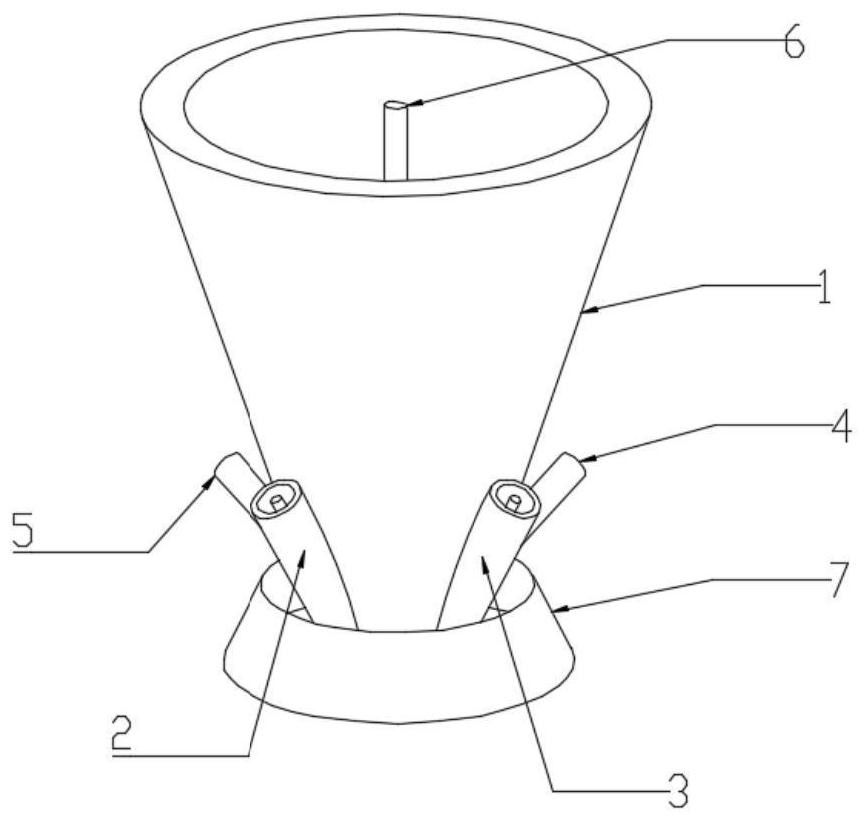

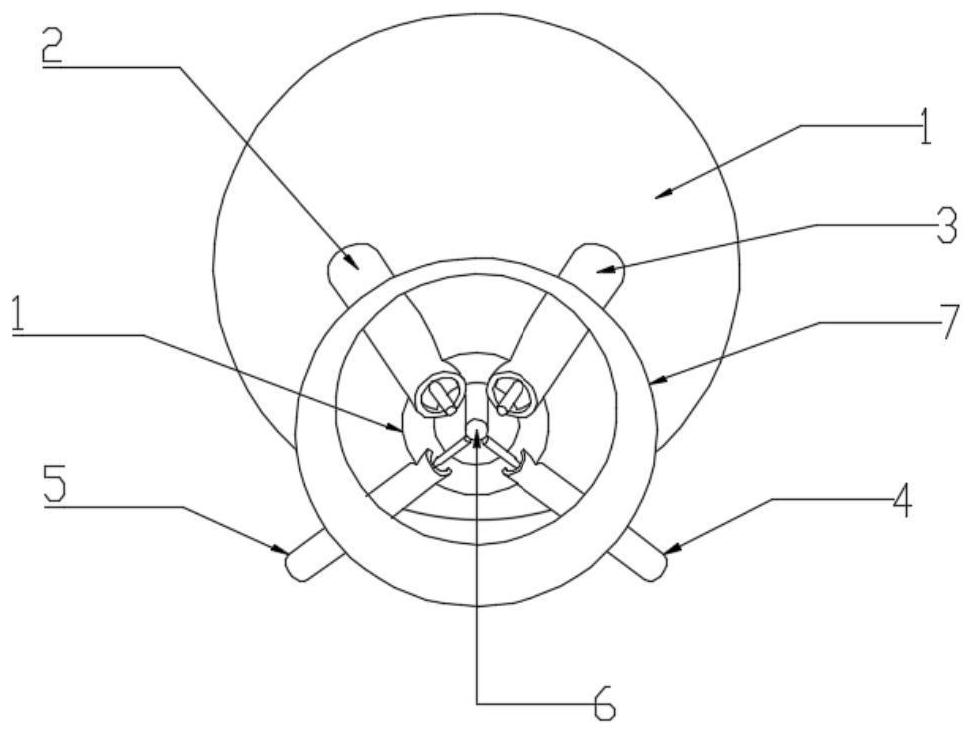

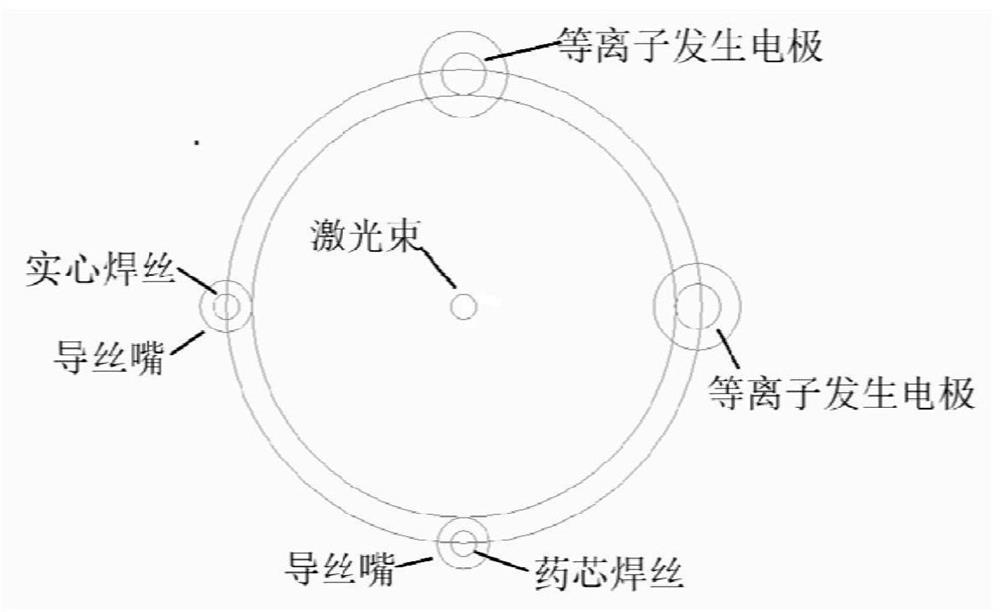

[0038] This embodiment provides a preparation device for a titanium alloy composite material, such as Figure 1~3 As shown, it includes a gun body, and the nozzle of the gun body is provided with a laser beam channel 1 , a first plasma generating electrode 2 , a second plasma generating electrode 3 , a first wire guide nozzle 4 and a second wire guide nozzle 5 . Wherein, the laser beam channel 1 communicates with the laser generator, the laser beam 6 transmitted by the laser beam channel 1 is located on the central axis, the first plasma generating electrode 2, the second plasma generating electrode 3, the first wire guide nozzle 4 and the second guide wire The nozzles 5 are evenly distributed on the outer circumference of the laser beam passage 1 and form an included angle with the central axis of the laser beam passage 1 . Specifically, the first wire guide nozzle 4 and the second wire guide nozzle 5 respectively form an angle of 50°-70° with the central axis of the laser be...

Embodiment 2

[0042] This embodiment provides a method for preparing a titanium alloy composite material, which is prepared using the titanium alloy composite material preparation device of Example 1, and the steps are as follows:

[0043] Set the first wire guide 4 and the second guide wire 5 to form an included angle of 60° with the central axis of the laser beam passage 1 respectively, and the first plasma generating electrode 2 and the second plasma generating electrode 3 are respectively connected to the central axis of the laser beam passage 1. The axis is at an angle of 25°, the laser power is 1000W, the plasma current is 50A, the deposition speed of solid wire with a diameter of 1.2mm is 1.2m / min, the wire feeding speed is 1.0m / min, and the core with a diameter of 1.6mm The deposition speed of the wire was 0.8 m / min, and the wire feeding speed was 1.0 m / min. Each layer is deposited sequentially along the Z direction in a layered manner, and each layer is deposited in a cross weaving...

Embodiment 3

[0045] This embodiment provides a method for preparing a titanium alloy composite material, which is prepared using the titanium alloy composite material preparation device of Example 1, and the steps are as follows:

[0046] Set the first wire guide 4 and the second guide wire 5 to form an included angle of 60° with the central axis of the laser beam passage 1 respectively, and the first plasma generating electrode 2 and the second plasma generating electrode 3 are respectively connected to the central axis of the laser beam passage 1. The axis is at an angle of 30°, the laser power is 1000W, the plasma current is 50A, the deposition speed of solid wire with a diameter of 1.2mm is 1.2m / min, the wire feeding speed is 1.0m / min, and the diameter of the drug core is 1.6mm The deposition speed of the wire was 0.8 m / min, and the wire feeding speed was 1.0 m / min. Each layer is deposited sequentially along the Z direction in a layered manner, and each layer is deposited in a circular...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap