Modified polypropylene master batch, modified melt-blown fabric material and improved melt-blown fabric processing method

A processing method, polypropylene technology, applied in the direction of non-woven fabrics, textiles and papermaking, etc., can solve the problems of high elongation at break, poor toughness, easy breakage, etc., to improve the stability of capture and charge storage, Effect of increasing crystallinity and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

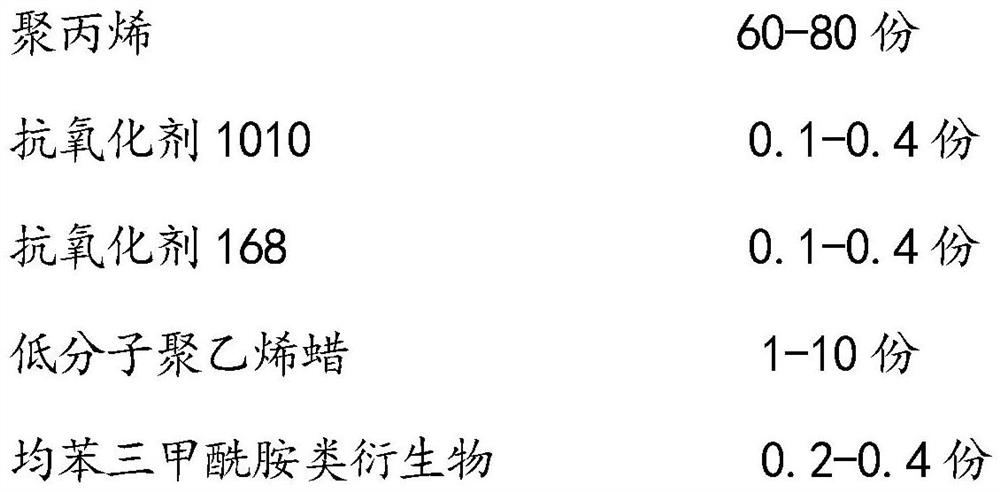

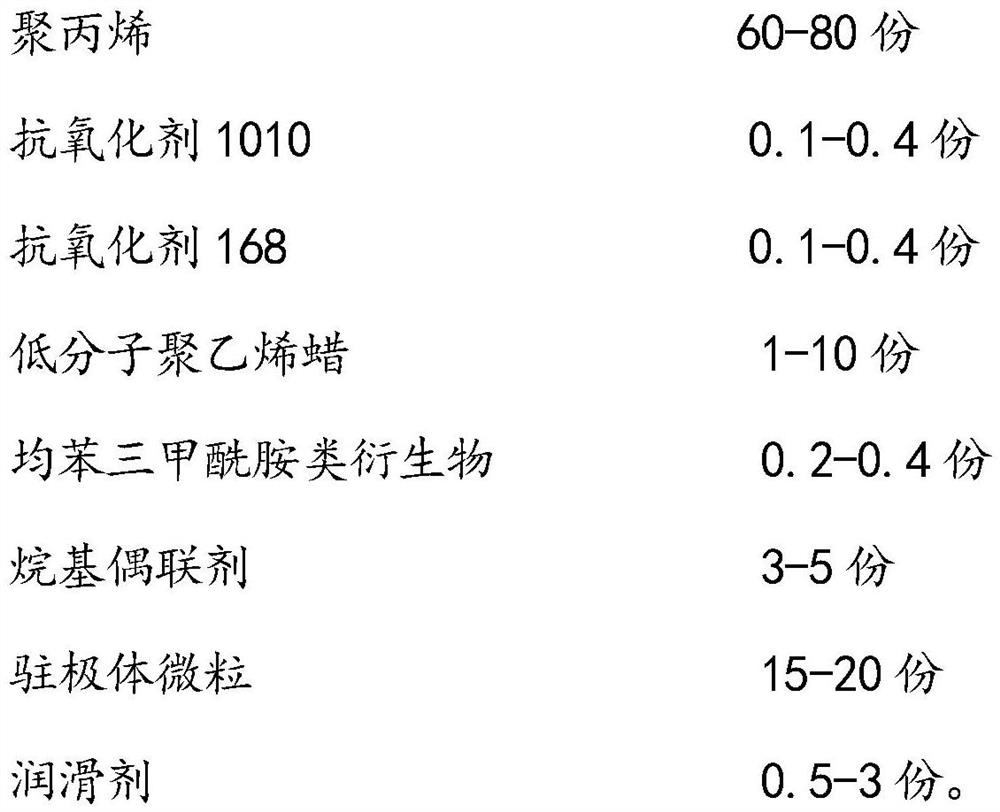

Method used

Image

Examples

Embodiment 1

[0058] Adopt 77 parts of polypropylene (melt index 1500g / 10min), 5 parts of low molecular weight polyethylene wax, 0.5 part of molecular weight regulator, 0.1 part of antioxidant 1010, 0.2 part of antioxidant 168, 2 parts of lubricant , 0.2 parts of trimesisamide derivatives, 3 parts of alkyl coupling agent, 12 parts of electret particles. Put them in a high-speed mixer and mix them in sequence, then transfer to a twin-screw co-extruder with an aspect ratio of 30 for melt blending and extrusion, the temperature of the melting section is 125-150°C, and after granulation, the particles are dried to obtain modified polystyrene Functional polypropylene masterbatch material.

Embodiment 2

[0060] Adopt 66 parts of polypropylene (melt index 1500g / 10min), 10 parts of low molecular weight polyethylene wax, 0.3 part of molecular weight modifier, 0.1 part of antioxidant 1010, 0.2 part of antioxidant 168, 2 parts of lubricant , 0.4 parts of trimesisamide derivatives, 5 parts of alkyl coupling agent, and 16 parts of electret particles. Put them in a high-speed mixer and mix them in sequence, then transfer to a twin-screw co-extruder with an aspect ratio of 30 for melt blending and extrusion, the temperature of the melting section is 125-150°C, and after granulation, the particles are dried to obtain modified polystyrene Functional polypropylene masterbatch material.

Embodiment 3

[0062] Adopt 71 parts of polypropylene (melt index 1500g / 10min), 8 parts of low molecular weight polyethylene wax, 0.4 part of molecular weight modifier, 0.1 part of antioxidant 1010, 0.2 part of antioxidant 168, 3 parts of lubricant , 0.3 parts of trimesisamide derivatives, 2 parts of alkyl coupling agent, 15 parts of electret particles. Put them into a high-speed mixer in order to mix them, transfer them to a twin-screw co-extruder with an aspect ratio of 30 for melt blending and extrusion, the temperature of the melting section is 125-150°C, and dry the particles after granulation to obtain the modified multi- Functional polypropylene masterbatch material.

[0063] In the actual preparation of melt-blown cloth, in addition to using the modified polypropylene masterbatch as a material, conventional polypropylene masterbatch can also be added, thereby reducing material costs and achieving an effective combination of cost and performance improvement of the final melt-blown clo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com