Eluting machine for purifying proteins

A protein purification and elution machine technology, applied in the field of protein purification, can solve the problems such as the inability to continuously carry out sample loading and washing, the influence of human factors, and the inability to purify proteins, etc. The effect of saving labor time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

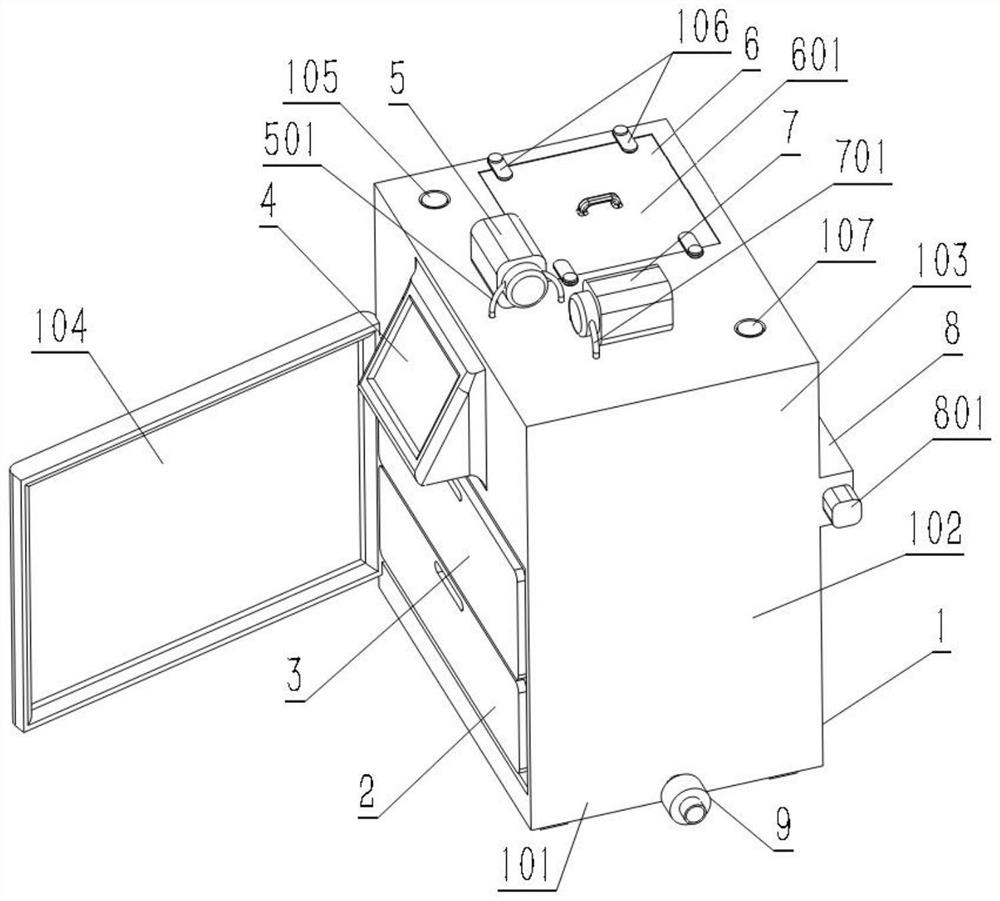

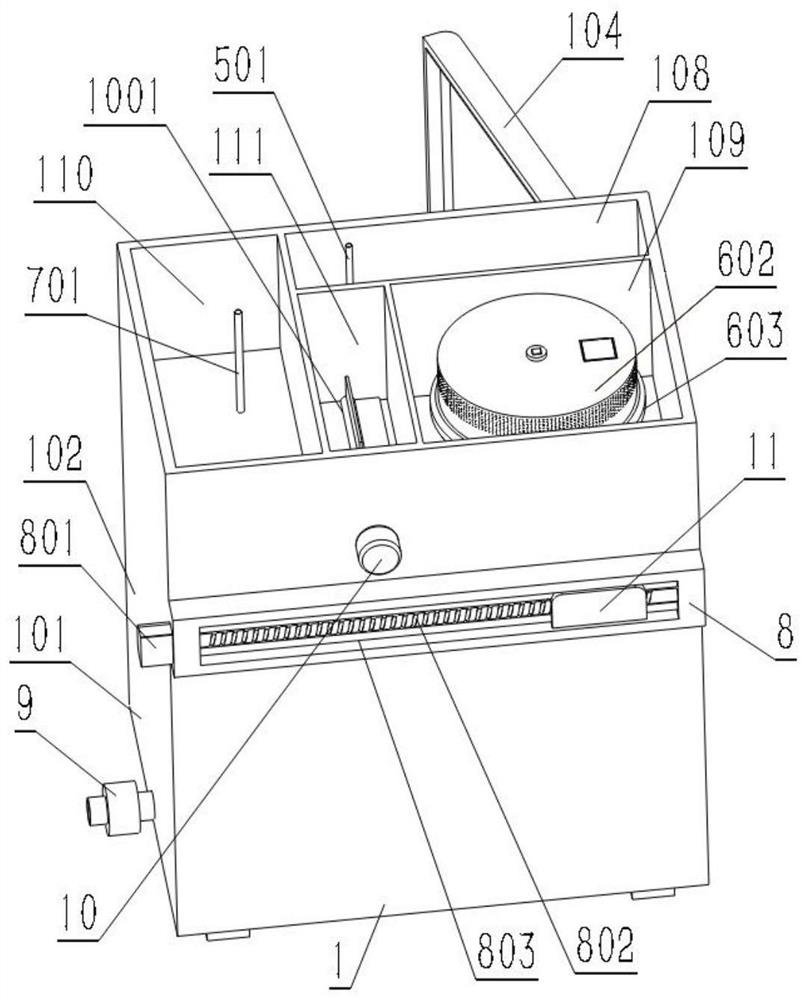

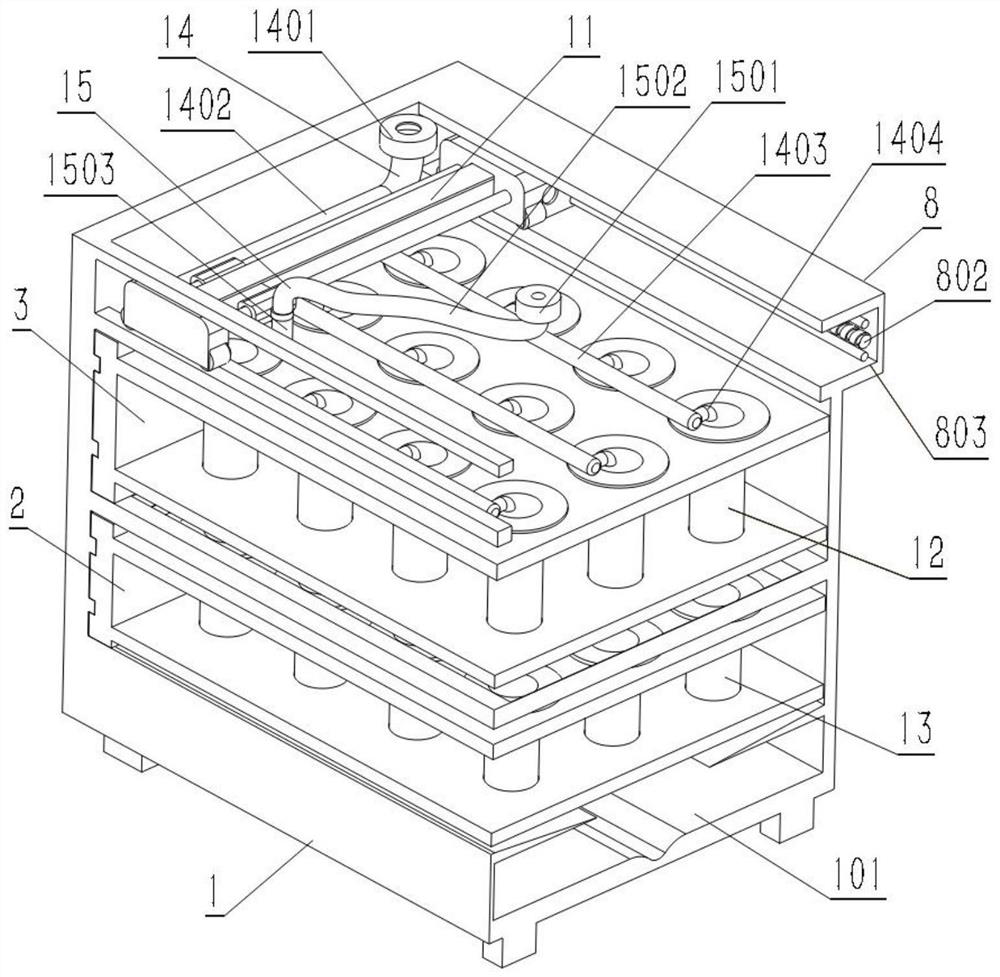

[0019] Such as Figure 1 to Figure 6As shown, a protein purification elution machine according to the present invention adopts a technical solution comprising a body 1, which is characterized in that the inner cavity of the body 1 is divided into a collection layer 101, a purification layer 101, and a purification layer from bottom to top. The reaction layer 102 and the storage layer 103, the storage layer 103 is vertically divided into a first eluent chamber 108, a protein solution chamber 109, a second eluent chamber 110, and an eluent mixing chamber 111 through a partition The top of the body 1 is provided with a first eluent feeding port 105 corresponding to the first eluent chamber 108, and a second eluent is provided at a position corresponding to the second eluent chamber 110. The feed port 107, the first eluent feed port 105 and the second eluent feed port 107 are all provided with a sealing cover plate, the top of the protein liquid cavity 109 is open and a rotating d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com