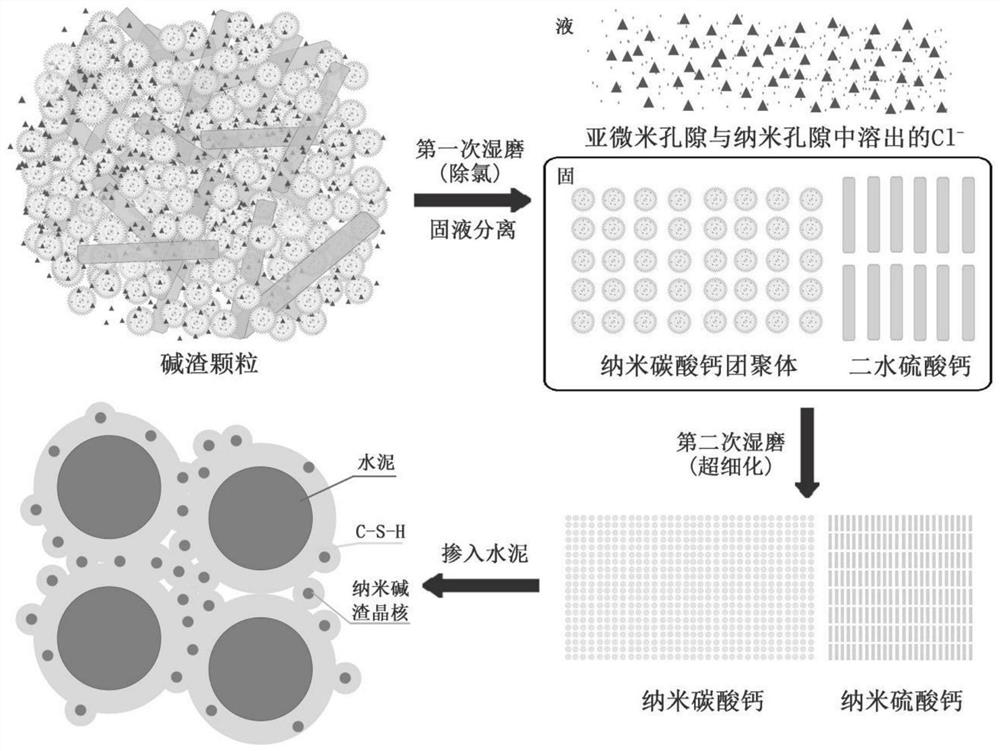

A kind of preparation method of inorganic salt early-strength agent for removing chlorine nano-alkali slag by wet grinding

A technology of early strength agent and inorganic salt, which is applied in the field of preparation of inorganic salt early strength agent for chlorine removal by wet milling, can solve the problems of large water consumption and low efficiency, and achieve small water consumption, simple process and good dispersion effect good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

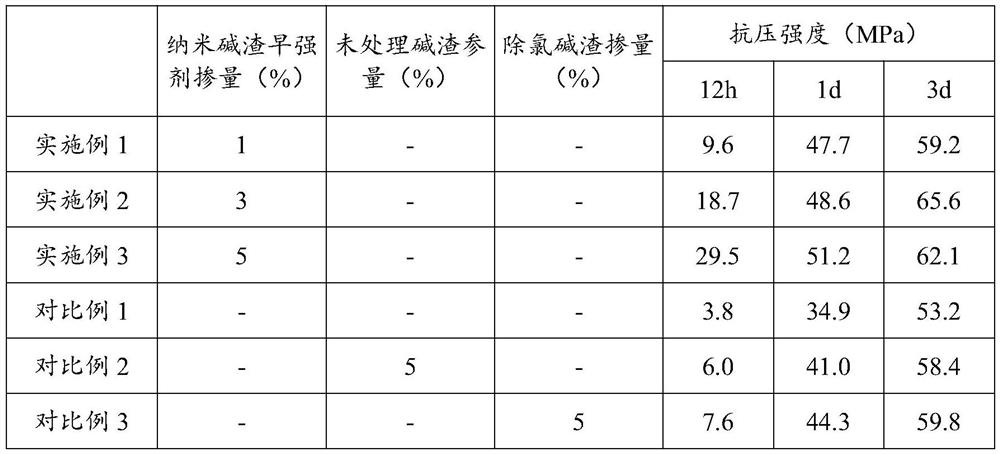

Examples

Embodiment 1

[0048] The specific steps of this embodiment are as follows:

[0049] (1) 30 parts by weight of alkali slag with a solid content of 90% is mixed with 64.5 parts by weight of water, and a suspension with a particle diameter of less than 1mm is obtained after sieving, and the solid content of the suspension is 30%.

[0050] (2) Mix the suspension, 0.135 parts by weight of ionic solubilizer and 400 parts by weight of agate balls, place them in a wet mill and grind them at a speed of 300rps to 400rps for 8min, and then sieve to obtain the chlor-alkali removal with a median particle size of 5 μm Slag slurry; wherein, the ionic solubilizer is composed of triethanolamine and propylene glycol mixed in a weight ratio of 2:1; agate balls are composed of 200 parts by weight of agate balls with a diameter of 2mm to 3mm, and 100 parts by weight of agate balls with a diameter of 3mm to 5mm Agate medium balls and 100 parts by weight of large agate balls with a ball diameter of 5 mm to 7 mm. ...

Embodiment 2

[0056] The specific steps of this embodiment are as follows:

[0057] (1) 30 parts by weight of alkali slag with a solid content of 70% is mixed with 64.5 parts by weight of water, and a suspension with a particle size of less than 1mm is obtained after sieving, and the solid content of the suspension is 40%.

[0058] (2) Mix the suspension, 0.105 parts by weight of ionic solubilizer and 400 parts by weight of agate balls, place in a wet grinder and grind for 9 minutes at a speed of 300rps to 400rps, and then sieve to obtain the chlor-alkali removal with a median particle size of 5 μm Slag slurry; wherein, the ionic solubilizer is composed of triethanolamine and propylene glycol mixed in a weight ratio of 1.5:1; agate balls are composed of 200 parts by weight of agate balls with a diameter of 2mm to 3mm, and 100 parts by weight of agate balls with a diameter of 3mm to 5mm Agate medium balls and 100 parts by weight of large agate balls with a ball diameter of 5 mm to 7 mm.

[...

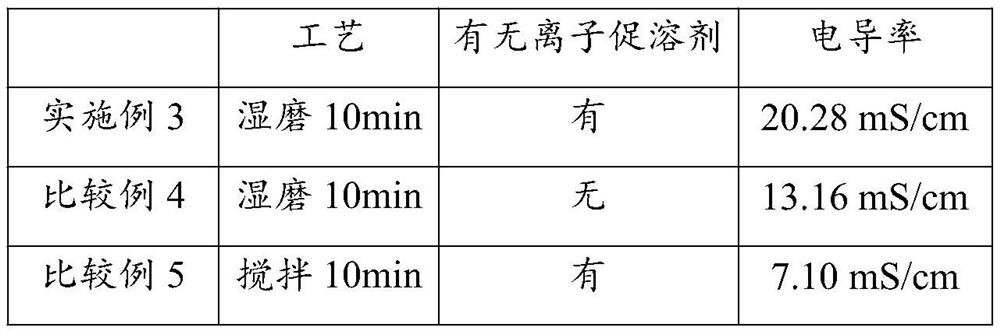

Embodiment 3

[0064] The specific steps of this embodiment are as follows:

[0065] (1) Get 30 parts by weight of alkali slag with a solid content of 50% and mix it with 64.5 parts by weight of water, and sieve to obtain a suspension with a particle size of less than 1 mm, and the solid content of the suspension is 30%.

[0066] (2) Mix the suspension, 0.075 parts by weight of ionic solubilizer and 400 parts by weight of agate balls, place in a wet grinder and grind for 10 minutes at a speed of 300rps to 400rps, and then sieve to obtain the chlor-alkali removal with a median particle size of 5 μm Slag slurry; wherein, the ionic solubilizer is composed of triethanolamine and propylene glycol mixed in a weight ratio of 1:1; agate balls are composed of 200 parts by weight of agate balls with a diameter of 2 mm to 3 mm, and 100 parts by weight of agate balls with a diameter of 3 mm to 5 mm. Agate medium balls and 100 parts by weight of large agate balls with a ball diameter of 5 mm to 7 mm.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com