Wire harness protector and wire harness

A wire harness protection and modification technology, which is applied in the field of pressure-sensitive adhesives to achieve the effects of improving the stability of use, increasing the strength, and enhancing protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of described modified polylactic acid fiber comprises the steps:

[0029] (1) Rinse the kaolin once with deionized water, then put it into the calciner for calcining, and take it out for subsequent use after completion;

[0030] (2) Immerse the kaolin treated in step (1) into the silane coupling agent solution, and filter out after 30-35 minutes for later use;

[0031] (3) The kaolin, nano-silver, and polylactic acid slices processed in step (2) are mixed together, firstly mixed, and taken out after 50 to 55 minutes to obtain the mixed material for subsequent use;

[0032] (4) Put the compounded material obtained in step (3) into a twin-screw extruder for extrusion processing, and then carry out spinning processing after completion, and finally go through cooling, drawing, and cutting.

[0033] During the calcination treatment described in step (1), the temperature in the calcination furnace is controlled to be 800-850° C., and the treatment time...

Embodiment 1

[0043] A wire harness protector, specifically, a non-woven fabric composed of mixed fibers containing polypropylene resin fibers, modified polylactic acid fibers, and modified basalt fibers is formed into a predetermined shape.

[0044] The corresponding weight fractions of the polypropylene resin fiber, modified polylactic acid fiber and modified basalt fiber in the non-woven fabric are 55%, 30% and 15% respectively.

[0045] The preparation method of described modified polylactic acid fiber comprises the steps:

[0046] (1) Rinse the kaolin once with deionized water, then put it into the calciner for calcining, and take it out for subsequent use after completion;

[0047] (2) Immerse the kaolin treated in step (1) in the silane coupling agent solution, and filter out after 30 minutes for subsequent use;

[0048] (3) The kaolin, nano-silver, and polylactic acid slices processed in step (2) are mixed together, and the mixing process is carried out first, and the mixing materi...

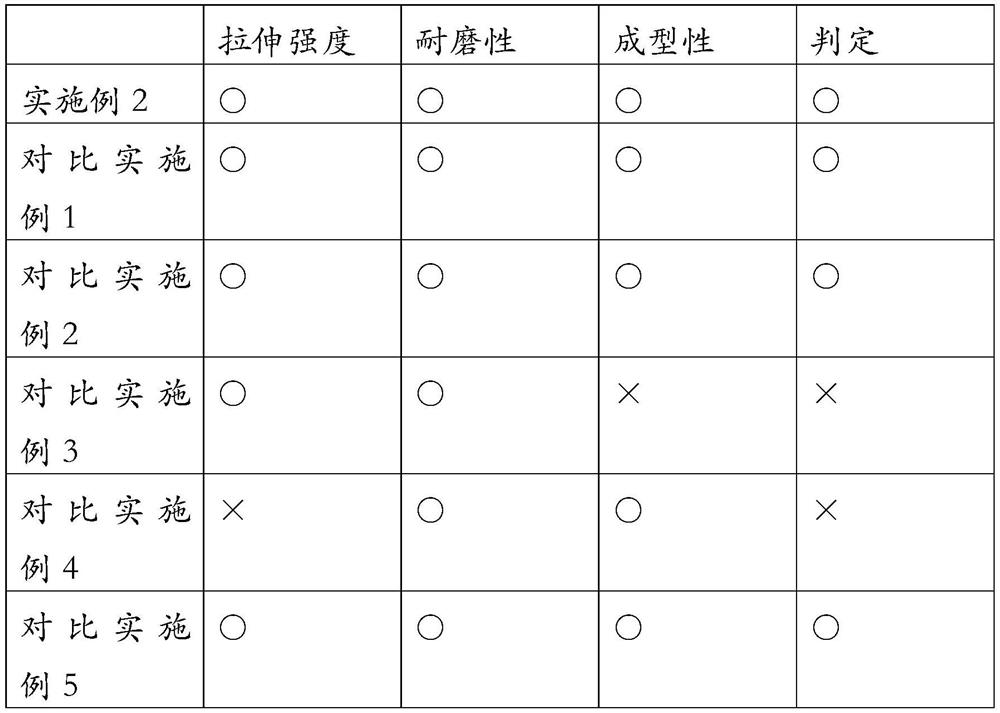

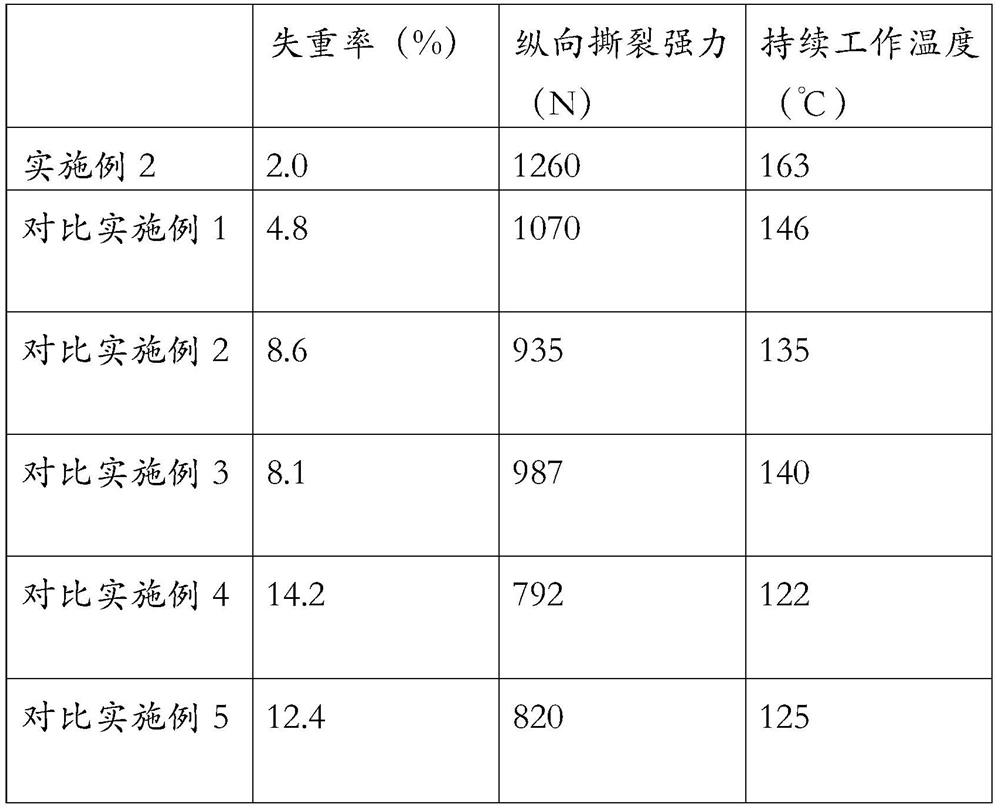

Embodiment 2

[0060] A wire harness protector, specifically, a non-woven fabric composed of mixed fibers containing polypropylene resin fibers, modified polylactic acid fibers, and modified basalt fibers is formed into a predetermined shape.

[0061] The corresponding weight fractions of the polypropylene resin fiber, modified polylactic acid fiber and modified basalt fiber in the non-woven fabric are 58%, 32% and 10% respectively.

[0062] The preparation method of described modified polylactic acid fiber comprises the steps:

[0063] (1) Rinse the kaolin once with deionized water, then put it into the calciner for calcining, and take it out for subsequent use after completion;

[0064] (2) Immerse the kaolin treated in step (1) in the silane coupling agent solution, and filter out after 31 minutes for subsequent use;

[0065] (3) The kaolin, nano-silver, and polylactic acid slices processed in step (2) are mixed together, and the mixing process is carried out first, and the mixing materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com