Self-deflection oil filtering device for oil-containing waste gas treatment

An oil filter device and waste gas treatment technology, which is applied in the fields of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of few purchasing channels, low output, and damage to filtration equipment, so as to reduce insufficient oil filtration, The effect of prolonging the service life and speeding up the oil filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

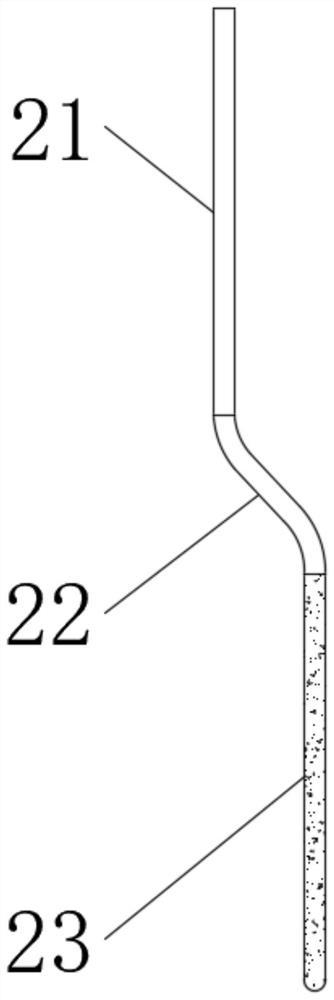

[0040] see Figure 1-2 , a self-deflecting oil filter device for oily waste gas treatment, comprising an oil filter plate 1, the lower end of the oil filter plate 1 is fixedly connected with a plurality of evenly distributed segmented oil filter fiber rods 2, and the oil filter plate 1 is provided with a plurality of Ventilation holes 3 are evenly distributed, and the segmental oil filter fiber rods 2 and air holes 3 are alternately distributed. The segmental oil filter fiber rods 2 include upper fixed oil filter fiber rods 21 and middle deflection transition rods distributed up and down in sequence. 22 and down moving oil filter fiber rod 23, and are connected with each other.

[0041] Both the upper fixed oil filter fiber rod 21 and the lower movable oil filter fiber rod 23 are made of oil-absorbing material, the middle deflection transition rod 22 is made of elastic material, and the oil absorption of the lower movable oil filter fiber rod 23 is better than that of the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com