Elemene cabazitaxel compound flexible emulsion and preparation method thereof

A flexible technology of cabazitaxel and compound formula, which is applied in the fields of pharmaceutical formulation, emulsion delivery, organic active ingredients, etc., can solve problems such as drug penetration into cells, drug resistance, safety, and problems, and achieve remarkable results. Prospect of clinical transformation application, reduction of toxicity and irritation, and effect of enhancing curative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

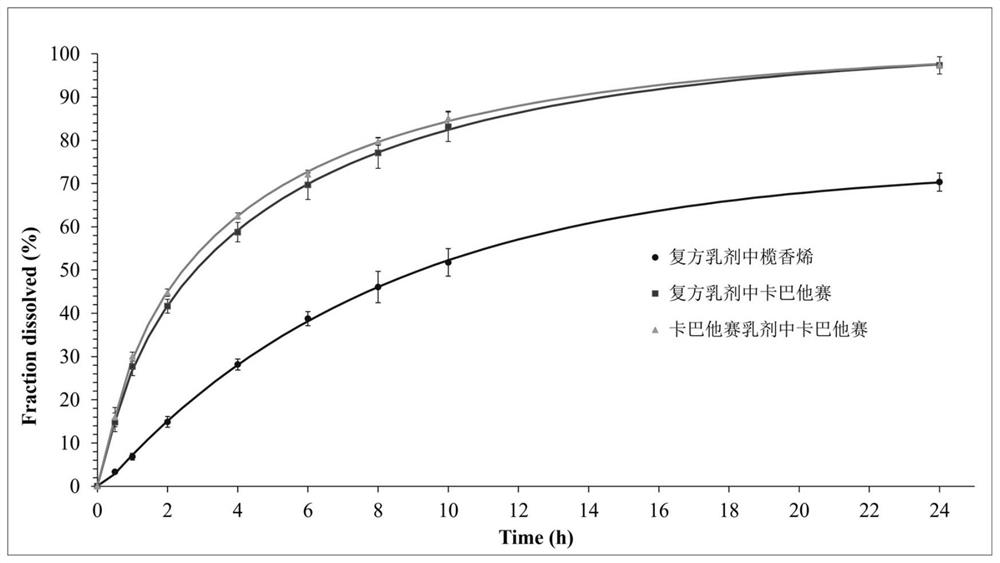

Embodiment 1

[0039] A kind of elemene-cabazitaxel compound flexible emulsion, calculated in 100mL, raw materials include: 0.5g elemene, 0.1g cabazitaxel, 5g medium-chain triglycerides, 2.5g soybean lecithin, 1g vitamin E polyethylene glycol Succinate, 2.6g glycerin, balance water.

[0040] The preparation method of above-mentioned elemene cabazitaxel compound flexible emulsion comprises the following steps:

[0041] (1) Preparation of the oil phase: melting medium-chain triglycerides, soybean lecithin, vitamin E polyethylene glycol succinate, elemene and cabazitaxel in a water bath at 80°C in proportion to obtain the oil phase;

[0042] (2) Water phase preparation: mix glycerin and water, heat and dissolve at 60°C to obtain a water phase;

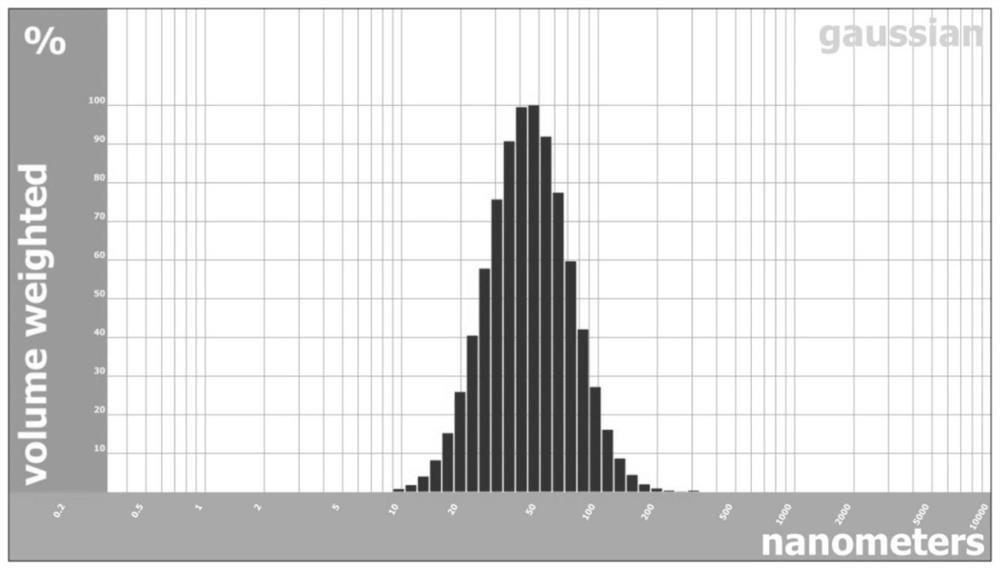

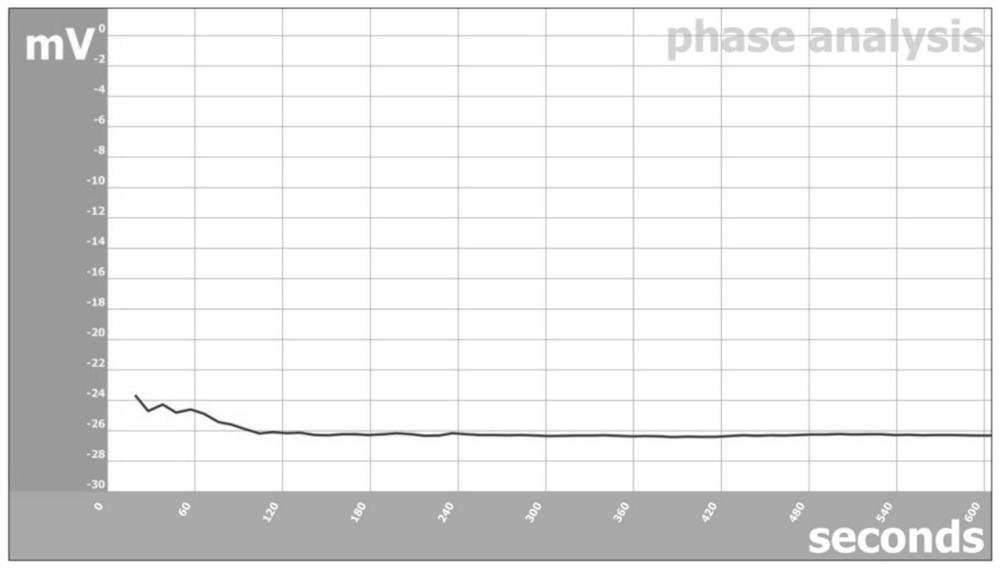

[0043] (3) Mix and homogenize: Add the oil phase to the water phase, cut in a 60°C water bath at 15000r / min for 30min, add 0.1mol / L sodium hydroxide / 0.1mol / L hydrochloric acid to adjust the pH of the system to 6.0, add water to make it 100mL , then 15...

Embodiment 2

[0045] A kind of elemene-cabazitaxel compound flexible emulsion, calculated in 100mL, raw materials include: 0.1g elemene, 0.1g cabazitaxel, 5g medium-chain triglycerides, 2.5g soybean lecithin, 1g vitamin E polyethylene glycol Succinate, 2.6g glycerin, balance water.

[0046] The preparation method of above-mentioned elemene cabazitaxel compound flexible emulsion comprises the following steps:

[0047] (1) Preparation of the oil phase: melting medium-chain triglycerides, soybean lecithin, vitamin E polyethylene glycol succinate, elemene and cabazitaxel in a water bath at 80°C in proportion to obtain the oil phase;

[0048] (2) Water phase preparation: mix glycerin and water, heat and dissolve at 60°C to obtain a water phase;

[0049] (3) Mix and homogenize: add the oil phase to the water phase, cut in a 60°C water bath at 15000r / min for 30min, add 0.1mol / L hydrochloric acid to adjust the pH of the system to 4.5, add water to 100mL, and then homogenize twice at 25000psi, Coo...

Embodiment 3

[0051] A kind of elemene-cabazitaxel compound flexible emulsion, calculated in 100mL, raw materials include: 2g elemene, 0.1g cabazitaxel, 5g medium-chain triglycerides, 2.5g soybean lecithin, 1g vitamin E polyethylene glycol succinate Ester, 2.6g glycerin, the balance is water.

[0052] The preparation method of above-mentioned elemene cabazitaxel compound flexible emulsion comprises the following steps:

[0053] (1) Oil phase preparation: melt medium-chain triglycerides, soybean lecithin, vitamin E polyethylene glycol succinate, elemene and cabazitaxel in a water bath at 70°C in proportion to obtain the oil phase;

[0054] (2) Water phase preparation: mix glycerin and water, heat and dissolve at 60°C to obtain a water phase;

[0055] (3) Mix and homogenize: Add the oil phase to the water phase, cut in a 60°C water bath at 15000r / min for 30min, add 0.1mol / L sodium hydroxide / 0.1mol / L hydrochloric acid to adjust the pH of the system to 6.0, add water to make it 100mL , homoge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| release amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com