Waste liquid collection device for operating room nursing

A waste liquid collection and operating room technology, applied in the field of medical appliances, can solve problems such as easy spillage, waste liquid cannot be effectively separated, single function, etc., and achieve the effect of improving functionality and sufficient and efficient solid-liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

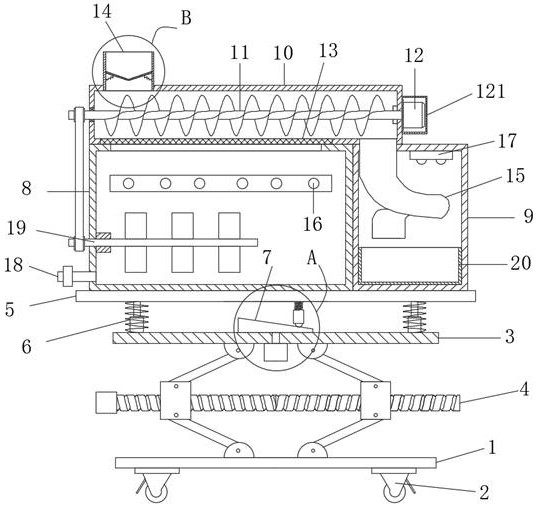

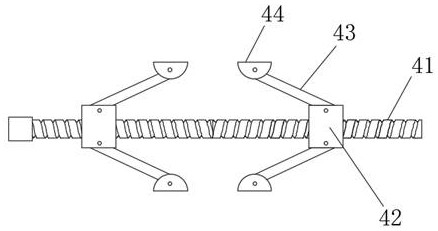

[0032] The invention provides a technical solution: a waste liquid collection device for nursing care in an operating room, including a base plate 1, rollers 2 are arranged at the four corners of the bottom end of the base plate 1, a lifting plate 3 is arranged above the base plate 1, and the lifting plate 3 and the base plate 1 is connected with a lifting mechanism 4, a mounting plate 5 is arranged above the lifting plate 3, and a spring telescopic rod 6 is arranged between the four corners of the bottom surface of the mounting plate 5 and the top surface of the lifting plate 3, and between the middle part of the lifting plate 3 and the middle part of the mounting plate 5 An up and down shaking mechanism 7 is provided, a waste liquid tank 8 is provided on the left side of the top of the mounting plate 5, a waste residue tank 9 is arranged on the right side of the waste liquid tank 8, and a cylinder 10 is provided on the top of the waste liquid tank 8, and the top of the cylinde...

Embodiment 2

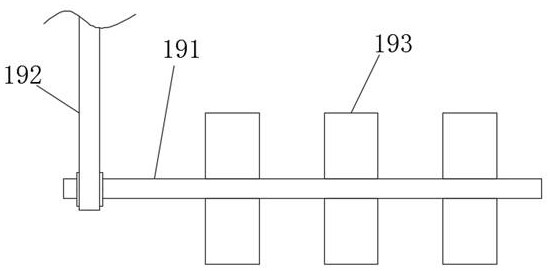

[0038] Compared with Embodiment 1, there are the following differences. The lower part of the left side wall of the waste liquid tank 8 is rotatably provided with a stirring mechanism 19. The stirring mechanism 19 includes a rotating shaft 191, and stirring blades 193 are uniformly arranged on the rod wall at the right part of the rotating shaft 191. The left end of the rotating shaft 191 runs through the left end of the waste liquid tank 8 and is connected with a transmission belt 192, and the upper part of the transmission belt 192 is connected with the left end of the conveying screw 11;

[0039] During specific implementation, after the medicament is added in the waste liquid tank 8, the stirring mechanism 19 can accelerate its mixing reaction efficiency, and the stirring mechanism 19 and the conveying screw 11 share a set of motors, which can reduce power consumption.

Embodiment 3

[0041] Compared with Embodiment 1, there are the following differences. The left and right sides of the inner cavity of the waste inlet nozzle 14 are correspondingly hinged with baffles 141, and a second spring 142 is connected between the bottom surface of the baffle 141 and the side wall of the adjacent waste inlet nozzle 14; When the solid waste is poured in, the buffering effect is activated, and it can also prevent the smell from overflowing to a certain extent.

[0042] In the solution, a protective cover 121 is provided around the driving motor 12 for protecting the motor.

[0043] In the scheme, the bottom of the waste slag discharge pipe (15) is a spiral pipe, which can reduce the risk of broken bottles of solid waste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com