Feed adhesive agent and preparation method thereof

A binder and feed technology, applied in the field of feed binder and its preparation, can solve the problems of veterinary drug and feed additive manufacturers' product promotion confusion, increase manpower, material resources and time costs, and fail to guarantee the uniformity of animals, etc., to achieve Save manpower, ensure uniformity and good palatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

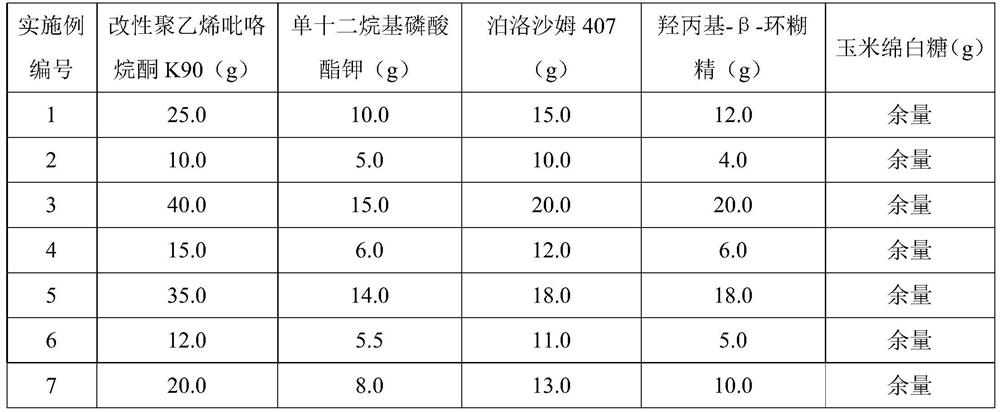

[0026] In order to make the description concise, the weight compositions of the feed adhesives of the present invention described in Examples 1-10 are given below in the form of a table, as shown in Table 1 for details.

[0027] The weight composition of every 100g of the present invention in table 1 embodiment 1-10

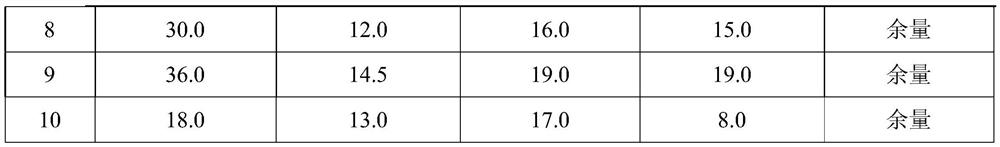

[0028]

[0029]

[0030] The preparation method of the described feed sticking agent of embodiment 1-10, comprises the following steps:

[0031] 1) premixing monododecyl potassium phosphate, poloxamer 407, hydroxypropyl-β-cyclodextrin and corn floss sugar to obtain a premix;

[0032] 2) Mix the premix and the modified polyvinylpyrrolidone K90 in an environment with a relative humidity not higher than 20%;

[0033] The modified polyvinylpyrrolidone K90 used in the present invention is obtained by modifying the polyvinylpyrrolidone K90 by a certain method. The specific preparation method is as follows: the polyvinylpyrrolidone K90 is dissolved in a 50% isopr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com